- Joined

- Nov 24, 2015

- Messages

- 79

- Reaction score

- 38

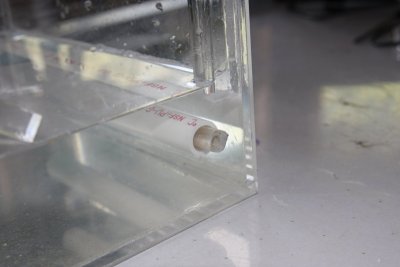

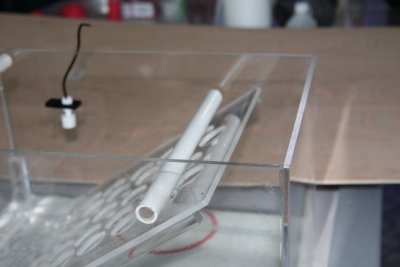

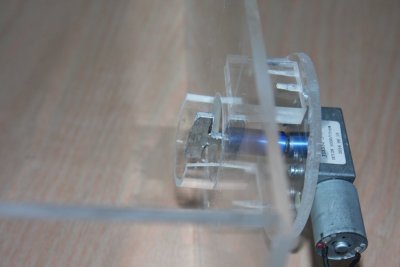

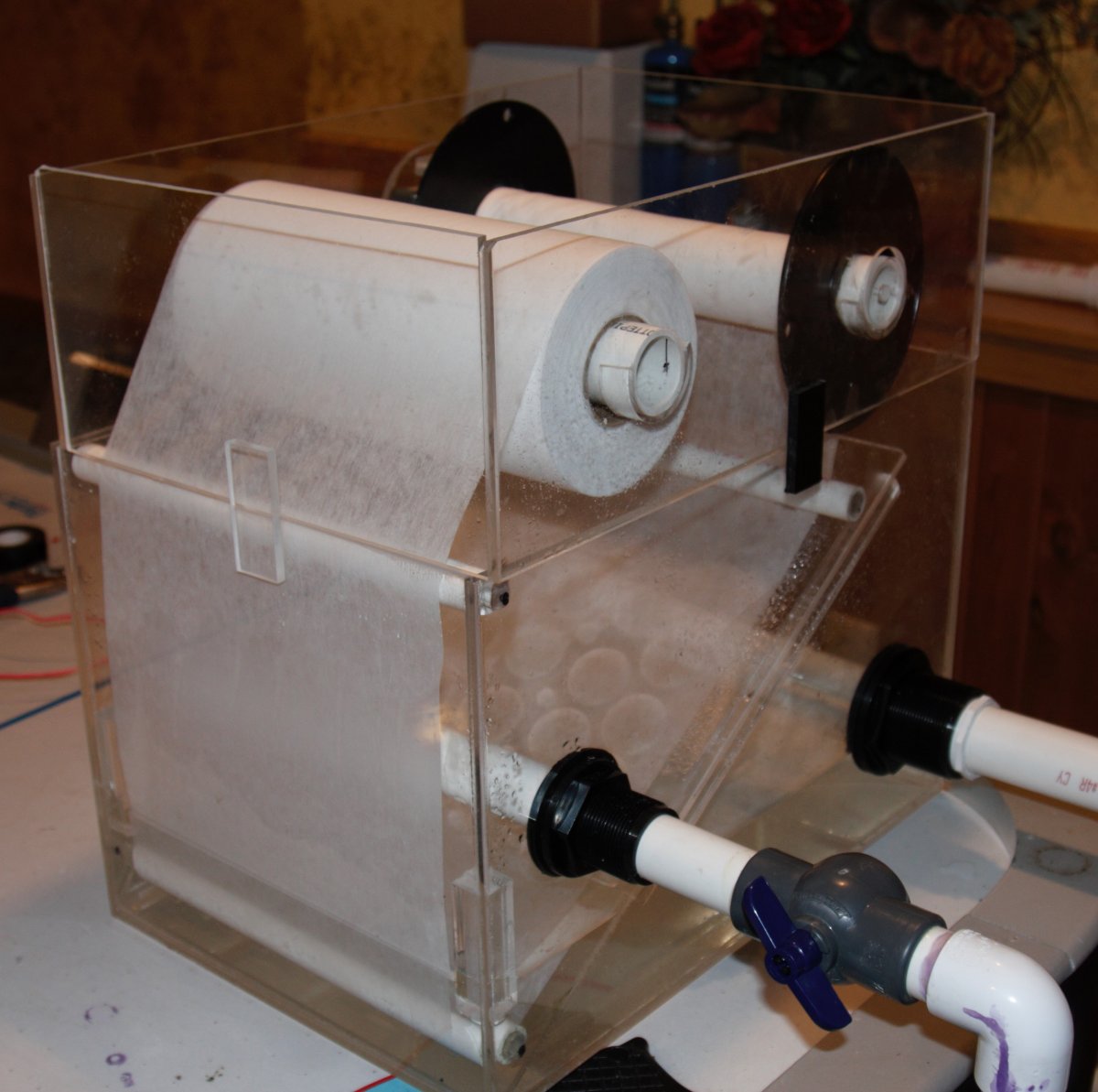

This is an image of a DIY automatic filter I just finished. I will post a video of it in operation later as well as a breakdown on the build and cost.

Credit to DBR_reef for his post that was the inspiration.

Credit to DBR_reef for his post that was the inspiration.