Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

imustbenuts office 65g revamp build

- Build Thread

- Thread starter imustbenuts

- Start date

- Tagged users None

Thanks @Chrisfish

Ordered plumbing but still need to order more. I guess I should have been satisfied to pick up the plumbing locally but wanted to make it look better than standard white sch 40 and a mix of gray valves. So, I have ordered sch 80 pipe and fittings to hopefully give it a more professional look.

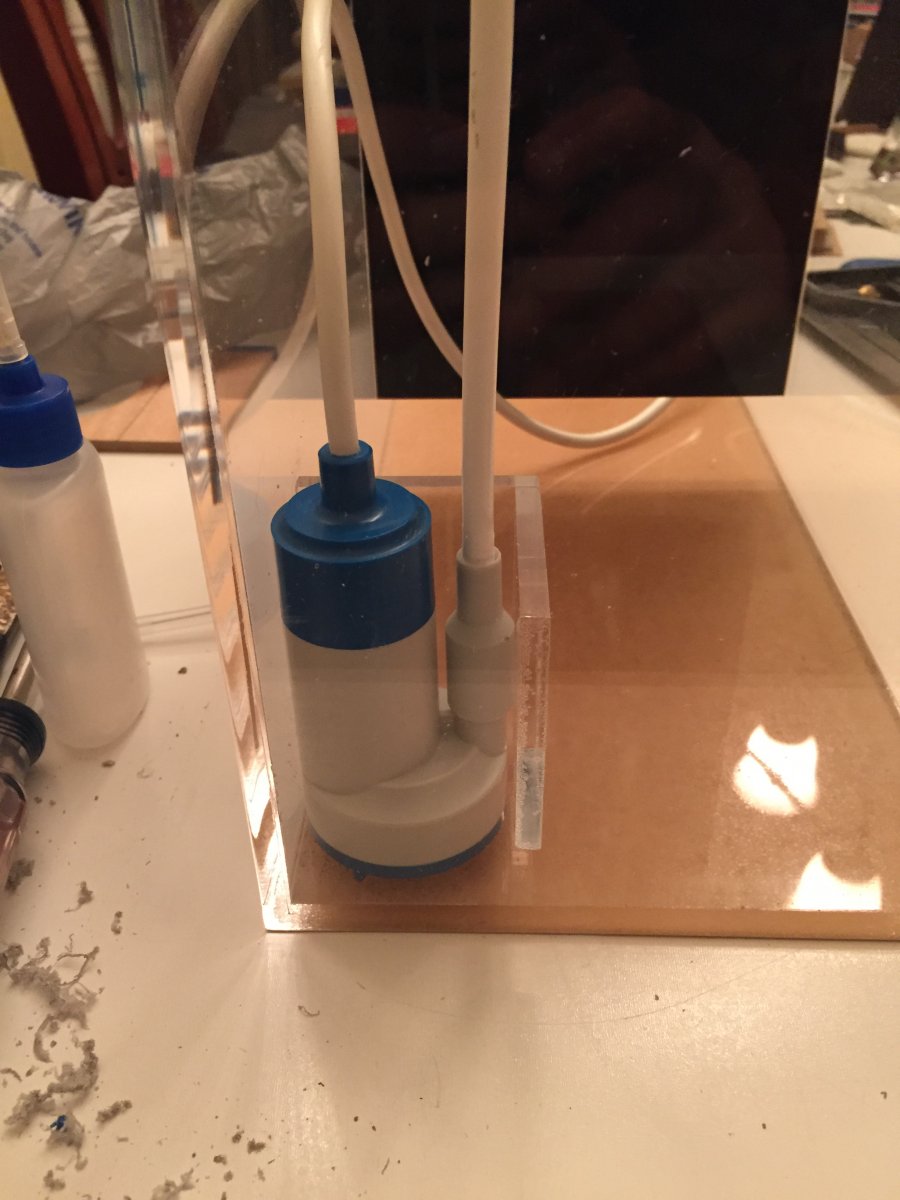

In the mean time, I put together a matching ATO container. I made a box inside for the Tunze pump to sit in. Hopefully It won't be too loud when it turns on and vibrates the container. I drilled the top for a bulkhead and am using push connect fittings to tie the ATO to the sump.

It holds 8gal of H2O. and measures 18x6.5x18. I still need to drill a 1/4" hole for the power cord to exit the ATO. I am pleased with it so far.

In the mean time, I put together a matching ATO container. I made a box inside for the Tunze pump to sit in. Hopefully It won't be too loud when it turns on and vibrates the container. I drilled the top for a bulkhead and am using push connect fittings to tie the ATO to the sump.

It holds 8gal of H2O. and measures 18x6.5x18. I still need to drill a 1/4" hole for the power cord to exit the ATO. I am pleased with it so far.

When I had to break the old tank down to get rid of the stand and clean up the water on the floor, I didn't try to keep the live rock. I let it sit outside for months. I brought it in and cleaned what junk off the rocks I could. Then, I baked the rock at 350* for 40 minutes. Once cooled I started curing it. It's been curing for about a month at this point. It put off a terrible stink for about 2 weeks. I'm thinking I'll pick up a piece of live rock from a LFS and introduce it to my curing rock.

How did you fix those molding trims, american style? It seems there are many miters at those moldings. Do you have a plan or cad? or some ref link?

Like how to fix this style of moldings?

Like how to fix this style of moldings?

I may not fully understand what you mean when you say fix. I will assume you are asking how the mouldings were cut and attached. I don't have any diagram or plans for the stand. It's all in my head.How did you fix those molding trims, american style? It seems there are many miters at those moldings. Do you have a plan or cad? or some ref link?

Like how to fix this style of moldings?

I made a traditional cabinet face frame using 1x4, actual measurement 3/4"x3-1/2" alder wood for the 3 open sides and used pocket holes to glue and screw them together. This made a 3 sided box to surround the 2x4 structure. I used glue and a finish nail gun to attach the face frame. I wanted to have fluted mouldings on the corners but couldn't find any in alder wood. So, I picked up 1x3 boards and used my router with a 3/16 round over bit to cut the flutes. I used 1x4 to box in the corners at the top and bottom. I cut the fluted 1x3 to fit between the boxed in corners creating like a Column with base and head. The finish moulding I used on the bottom and top is an alder wood base board with the routed profile already cut. I used a miter saw to cut the base board and wrap the bottom and top. The base board is glued and nailed. In the prior pictures, you can see I used a quarter round moulding to fit on the sides of the fluted corners. I didn't like that look and cut them down 1/8" so they weren't flush. I still didn't like the round corners so I turns them around and used the square back instead. The main thing I learned was to layer the wood to build the look you want.

I hope this helps you make sense of the build.

Last edited:

Yes, by fixing I meant attachments.

Thank you for a brief explanation, but still not been able to understand a thing about it. I'll point out the things i wanna understand about the mouldings, by marking your picture and posting again. What do you mean by base board? Is it that you attach those mouldings on a plank the way you wanna and then cut it? You make a lot of sense, but I'm the one not been able to grasp it. May be the cultural differences or you can say geographical difference. Some terms are like bullet shots to me. Lol

Thank you for a brief explanation, but still not been able to understand a thing about it. I'll point out the things i wanna understand about the mouldings, by marking your picture and posting again. What do you mean by base board? Is it that you attach those mouldings on a plank the way you wanna and then cut it? You make a lot of sense, but I'm the one not been able to grasp it. May be the cultural differences or you can say geographical difference. Some terms are like bullet shots to me. Lol

Baseboard is used at the bottom of walls in our homes where it meets the floor.Yes, by fixing I meant attachments.

Thank you for a brief explanation, but still not been able to understand a thing about it. I'll point out the things i wanna understand about the mouldings, by marking your picture and posting again. What do you mean by base board? Is it that you attach those mouldings on a plank the way you wanna and then cut it? You make a lot of sense, but I'm the one not been able to grasp it. May be the cultural differences or you can say geographical difference. Some terms are like bullet shots to me. Lol

@TherealplexiG i would suggest you search YouTube using the terms you don't know. It should bring up videos for you to watch. Things like, "install baseboard, layering moulding, etc". You might be able to watch some of the techniques I used for the stand.

An example of baseboard install. I didn't cope my inside corners because I had 90* corners. So, I used a miter saw on inside and outside corners.

If you look at the back corner behind the one you circled. You can see the layers of wood. 2x4, 1x4, 1x3 on top. It's not 1 piece. Search cabinet making face frames and decrative trim moulding install. This is face framing

Last edited:

Now you got me rolling baby. Thanks a tonne. If I succeed in making those kinda stands, all the credit would be due to you.An example of baseboard install

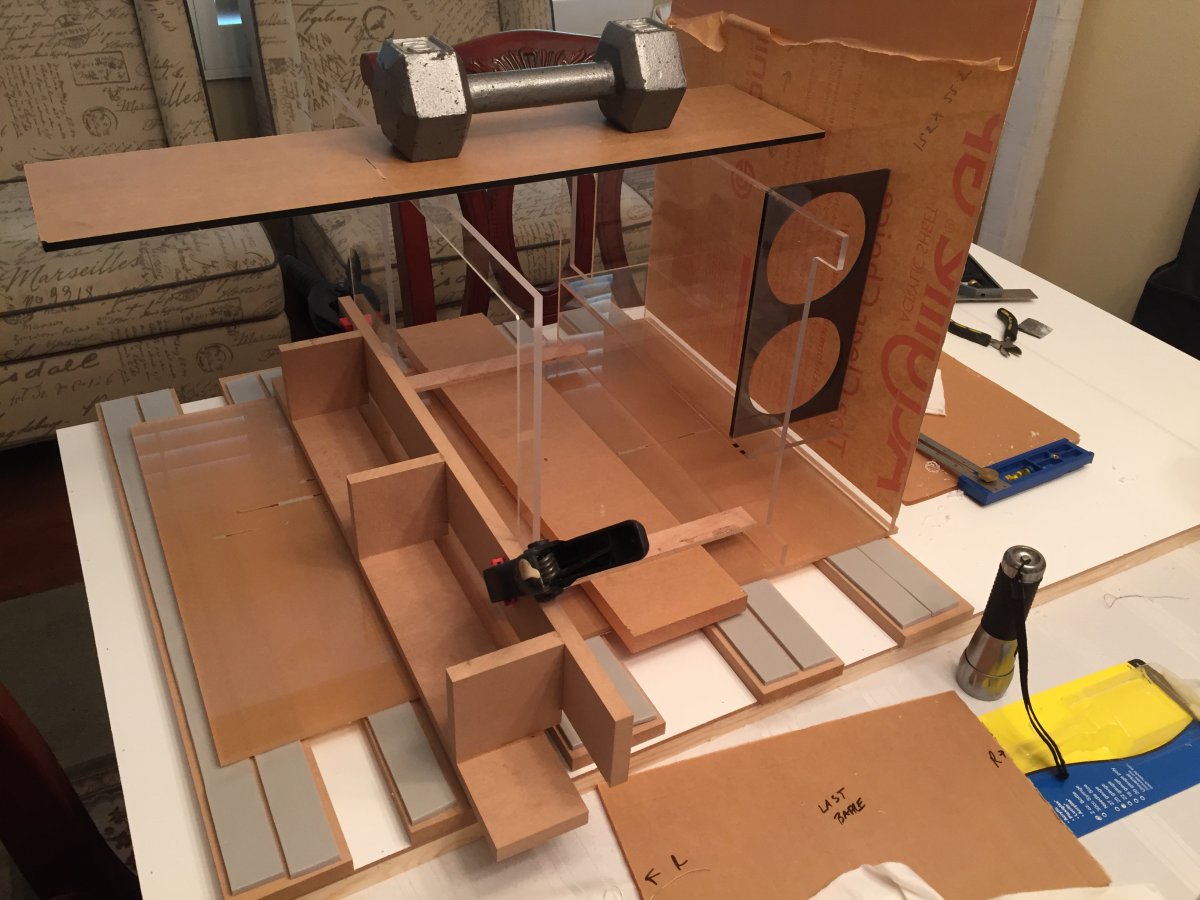

I first welded the short riser and filter sock plate together. After it set, about 30 min, I welded that to the baffle. Once set, I welded the baffle to the sump wall. After that set for a day I turned the sump to its side so I could weld the riser and filter sock plate to the other sump wall. Make sure you do your cut outs for the socks and water flow before you weld them together.Hey,

How did you do this part? the whole first baffle with filter sock holder and a partition? could ya tell me the steps what goes first and how?

Last edited:

Your edges seem to be most perfect, what bit you using for edge prep? how have you set up your fence?

I use this bit. http://www.precisionbits.com/solid-...-bit-spiral-upcut-1-4-shank-yonico-14121.html

I thinks it's a Chinese bit so you may have a local supplier.

I used the same method discussed in the acrylic thread. I set up a straight edge clamp, http://www.eemersontool.com , the distance I needed away from the bit. I did not use the router table fence. I rough cut the pieces 1/4" larger and used the router to trim to proper size. If I had 6 panels that needed to be say 15", I would run all 6 pieces on one side to make sure they were all cut to exact same size before changing the straight edge position and finishing on the other edge. Make sure to keep pressure on your panel and run against the spin of the bit.

Last edited:

Quick update; pics of the plumbing.

It took a while to figure out but got it done and I think it turned out ok. 1" return hard plumbed with 3 valve manifold up to a tee and reduced to 3/4" then reduced to 1/2" at the bulkhead . 2 1" drains. 1 with gate valve to tune syphon so 25% of water flows through second drain. The first drain to the sump and the second drain to the refugium.

It took a while to figure out but got it done and I think it turned out ok. 1" return hard plumbed with 3 valve manifold up to a tee and reduced to 3/4" then reduced to 1/2" at the bulkhead . 2 1" drains. 1 with gate valve to tune syphon so 25% of water flows through second drain. The first drain to the sump and the second drain to the refugium.

Nice work!!! Still in progress so it's becoming better and better!!! [emoji106][emoji106][emoji106]