Its all pluged to outlets.That is pretty awesome. I am thinking more simple for my first try. Do you have all your equipment hard wired to the controller or is it plugged in to an outlet?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Your Resident Electrician for all your electrical questions!

- Thread starter Young Frankenstein

- Start date

- Tagged users None

Young Frankie  do you know cable? I know it's not electric but I thought it would be worth a shot. I have dish for tv and cox for Internet. The dish and cox both join outside the house and then are distributed to the rooms. What I want to do is change what rooms they go to.

do you know cable? I know it's not electric but I thought it would be worth a shot. I have dish for tv and cox for Internet. The dish and cox both join outside the house and then are distributed to the rooms. What I want to do is change what rooms they go to.

What used to be my media room (dish) now is my fish room and I want Internet in there. And I also want dish in my guest room.

outside the house is a box with a birds best of wires.

I have tracked one wire from the ground that gets split into 6 for cable.

Dish has (if I remember right) two that go from the dish to the box outside and then join into one. Then split into two and into the house.

My thought is that I should just be able to unplug one of the wires and move it over (either from the dish to cable or visa versa) and be done. I have done this to no avail.

Are there any tips that you know of? If this needs to be moved to a different thread that's fine. I just want to be able to use all of my tv's again and have Internet on my computer.

What used to be my media room (dish) now is my fish room and I want Internet in there. And I also want dish in my guest room.

outside the house is a box with a birds best of wires.

I have tracked one wire from the ground that gets split into 6 for cable.

Dish has (if I remember right) two that go from the dish to the box outside and then join into one. Then split into two and into the house.

My thought is that I should just be able to unplug one of the wires and move it over (either from the dish to cable or visa versa) and be done. I have done this to no avail.

Are there any tips that you know of? If this needs to be moved to a different thread that's fine. I just want to be able to use all of my tv's again and have Internet on my computer.

I need a cable guy here people .......................come on .........Young Frankiedo you know cable? I know it's not electric but I thought it would be worth a shot. I have dish for tv and cox for Internet. The dish and cox both join outside the house and then are distributed to the rooms. What I want to do is change what rooms they go to.

What used to be my media room (dish) now is my fish room and I want Internet in there. And I also want dish in my guest room.

outside the house is a box with a birds best of wires.

I have tracked one wire from the ground that gets split into 6 for cable.

Dish has (if I remember right) two that go from the dish to the box outside and then join into one. Then split into two and into the house.

My thought is that I should just be able to unplug one of the wires and move it over (either from the dish to cable or visa versa) and be done. I have done this to no avail.

Are there any tips that you know of? If this needs to be moved to a different thread that's fine. I just want to be able to use all of my tv's again and have Internet on my computer.

Do you happen to know what the phase angle is for a standard 120v outlet? I'm trying to calculate what my current draw is based on the posted wattage for each device.

To calculate Amps, divide watts by voltage ex 500W/120V=4.16Amps

okP=VIcos(phase-angle), but I thought the only instance where you could simply divide power by voltage was for DC (phase angle of 0)?

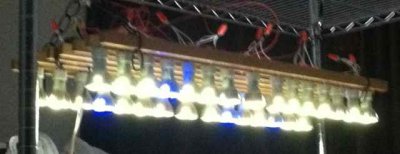

Any thoughts on the current design of my light?

Also any suggestions on "finishing" the top half so it could be safe to move around? I was considering just "building in" the top with hardboard secured to a small interior frame - just big enough to contain the wiring.

Last, how about "properly" wiring power into the ficture? Say I have the hardboard box built above...what's the correct way to enter the box with power and best way to secure the cable inside?

I'd also like wiring suggestions in general.....this works well, but it seems like there should be a much more efficient or otherwise better way to wire these up. (All sockets are wired in parallel.)

(Sorry for the "awesome" phtotos.)

The next iteration will actually be three "rails" of 16 bulbs each (vs two "rails" as in the photos), so that's going to be a lot of connections! (96!) Tips will be appreciated!

-Matt

Also any suggestions on "finishing" the top half so it could be safe to move around? I was considering just "building in" the top with hardboard secured to a small interior frame - just big enough to contain the wiring.

Last, how about "properly" wiring power into the ficture? Say I have the hardboard box built above...what's the correct way to enter the box with power and best way to secure the cable inside?

I'd also like wiring suggestions in general.....this works well, but it seems like there should be a much more efficient or otherwise better way to wire these up. (All sockets are wired in parallel.)

(Sorry for the "awesome" phtotos.)

The next iteration will actually be three "rails" of 16 bulbs each (vs two "rails" as in the photos), so that's going to be a lot of connections! (96!) Tips will be appreciated!

-Matt

Believe it or not, using tie wraps to make electrical panels neater, is not suggested by NEC or local inspectors, this issue came up about 5 years ago. It is safer but more messy to leave wiring loose the way you have it. You are using wire nuts, perfectrly fine, all looks good to me. The problem is the splices can NOT be contained in a flammable enclosure. Since you have a bunch of them you need a metal enclosure to make this fixture safe. There is several ways to do that, you can get flat metal and built a frame, use a 1900 box over each bulb with a blank cover, or go to your local supply house and get 4" x 10" boxes and drill them. The idea is to have a non flammable grounded enclosure, how it looks like it does not matter. As far as your wiring, I am assuming you are using #12 THHN to wire in parallel, don't go over 15A and you will be fine. Make shure all wire nuts are tight. I would also use a aluminum L metal bar from HD$5 each, to mout the bulb sockets instead of wood. Hope this helps

Last edited:

That's pretty cool of you to offer up your services like that. I don't have an issue right now but it's good to know I have a place to go if something comes up. Thank you

Not a problem, others have helped me always, so if I can offer some advice, its a pleasureThat's pretty cool of you to offer up your services like that. I don't have an issue right now but it's good to know I have a place to go if something comes up. Thank you

Believe it or not, using tie wraps to make electrical panels neater, is not suggested by NEC or local inspectors, this issue came up about 5 years ago. It is safer but more messy to leave wiring loose the way you have it. You are using wire nuts, perfectrly fine, all looks good to me. The problem is the splices can NOT be contained in a flammable enclosure. Since you have a bunch of them you need a metal enclosure to make this fixture safe. There is several ways to do that, you can get flat metal and built a frame, use a 1900 box over each bulb with a blank cover, or go to your local supply house and get 4" x 10" boxes and drill them. The idea is to have a non flammable grounded enclosure, how it looks like it does not matter. As far as your wiring, I am assuming you are using #12 THHN to wire in parallel, don't go over 15A and you will be fine. Make shure all wire nuts are tight. I would also use a aluminum L metal bar from HD$5 each, to mout the bulb sockets instead of wood. Hope this helps

Interesting!

tie wraps

It's not so apparent in my "awesome" photos, but after wiring everything up I did wire-tie each bundle of wires about 1/2" under each wire nut just - theory being to make sure if anything accidentally got tugged, it would be tug the bundle and not tug one wire loose from the nut. Trying to avoid anything that could lead to sparks! Not sure if this was a good theory or not now.

the missing enclosure

The flammable enclosure is what's been really killing me...wood would make the solution both inexpensive and simple to do. Metal solutions I'm aware of are neither simple to implement nor inexpensive. Seems there's a lot of room for a compromise solution that's inexpensive and relatively simple, yet still safe - but it's eluding me so far.

One box-per-bulb makes a nice, simple solution, but that's between 30 and 50 boxes - not cheap unless there's a metal box that costs around a buck or less. Bigger boxes are never big enough, which complicates things (drilling, fabricating) and they are usually pricey as well. Hrm...

the wiring

The sockets are pre-wired with 20 gauge (is that the same as #20?), so that (or 18 gauge) is what I used for the parallel interconnects as well. The incoming power cable is 16 gauge and connects through a 4-terminal connector block. Does it makes sense to use 12 gauge (assuming that's what #12 means....don't know what THHN means) when the socket wires are so small? If possible, please explain?

For what it's worth, the entire load is only about 100VA (83 watts or so) and the individual bulbs only get barely warm to the touch.

too many connections

It seems like there should be plenty of high-density wiring scenarios like this where someone has already figured out a super-genius way of managing or combing a bunch of parallel connections like this. The best I've found is a terminal connector block with a jumper across one side of the block. With only 6" leads from the sockets, this is a limited solution - I wind up making more connections and jumper wires just to get all the sockets to the terminal block.

Is there a DIN rail solution that you know of which would apply? I know those are big in telecom equipment that has lots of connections, but I don't know how similar those installations would be to mine.

At least one DIY'er has taken the step to just wire the sockets to each other in parallel, but he's splicing and taping - which I'm not so confident in as a connecting solution. You can see details of his process here to see what I mean. It clearly works for him, but electrically speaking does this method seem legit?

-Matt

The wiring I like its not bad, if the entire load is less than 100w than install a 500w fuse inline to protect the 16 and 20g wiring. I like the fixture, it all looks ok, the problem is with fire hazard and we dont wat that. Cost is also a factor with everything we do in the DIY forum, we dont want to spend more than it costs to gut a prefab fixture ad we also lean towards custom made, that is priceless. If you go to the roof section of HD you will fing a very thin stainless metal roll used for roof repairs, I thik itcomes in 20' x 1'rolls for about $ 20.00. wrap that metal or protect the wiring from being exposed with that metal frame, If there is arching or a short that metal will protect against a fire. Install a .5 to 1A fuse inline and you good to go, also dont forget to ground the metal cover. What type of bulbs are you using ? THHN is the type of insulation we use in the electrical field.Interesting!

tie wraps

It's not so apparent in my "awesome" photos, but after wiring everything up I did wire-tie each bundle of wires about 1/2" under each wire nut just THATS FINE- theory being to make sure if anything accidentally got tugged, it would be tug the bundle and not tug one wire loose from the nut. Trying to avoid anything that could lead to sparks! Not sure if this was a good theory or not now.ITS OK

the missing enclosure

The flammable enclosure is what's been really killing me...wood would make the solution both inexpensive and simple to do. Metal solutions I'm aware of are neither simple to implement nor inexpensive. Seems there's a lot of room for a compromise solution that's inexpensive and relatively simple, yet still safe - but it's eluding me so far.ITS GOT TO BE METAL

One box-per-bulb makes a nice, simple solution, but that's between 30 and 50 boxes I AGREE- not cheap unless there's a metal box that costs around a buck or less. Bigger boxes are never big enough, which complicates things (drilling, fabricating) and they are usually pricey as well. Hrm...

the wiring

The sockets are pre-wired with 20 g (is that the same as #20?), so that (or 18 g) is what I used for the parallel interconnects as well. The incoming power cable is 16 g and connects through a 4-terminal connector block. Does it makes sense to use 12 g (assuming that's what #12 means....don't know what THHN means) when the socket wires are so small? If possible, please explain?

For what it's worth, the entire load is only about 100VA (83 watts or so) and the individual bulbs only get barely warm to the touch.

too many connections

It seems like there should be plenty of high-density wiring scenarios like this where someone has already figured out a super-genius way of managing or combing a bunch of parallel connections like this. The best I've found is a terminal connector block with a jumper across one side of the block. With only 6" leads from the sockets, this is a limited solution - I wind up making more connections and jumper wires just to get all the sockets to the terminal block.

Is there a DIN rail solution that you know of which would apply? I know those are big in telecom equipment that has lots of connections, but I don't know how similar those installations would be to mine.

At least one DIY'er has taken the step to just wire the sockets to each other in parallel, but he's splicing and taping - which I'm not so confident in as a connecting solution. You can see details of his process here to see what I mean. It clearly works for him, but electrically speaking does this method seem legit?

-Matt

They are GU10-base, MR16-style LEDs. Three 1-watt LEDs in each bulb. 30° lenses on each LED. You get almost 6" diameter of coverage per bulb.

Thanks for all the feedback and great tip on the rolled stainless - will have to check for it next time I'm at the home store!

-Matt

Thanks for all the feedback and great tip on the rolled stainless - will have to check for it next time I'm at the home store!

-Matt

Let me know if you did find the metal in HD

What do I need to build LED setup?

I have read DIY led threads and I need help with what electrical parts I need to accumulate for the build. I understand I will probably need a couple drivers Meanwells to be exact. Going with Cree LEDS and the accessories needed for them ex.(heat sink), but then to my understanding if I want to make them auto dimmable like sunrise and sunset, then what other pieces of equipment or hardware do I need? I have read people mention an arduino. But I need more knowledge on functions of devices, capabilities, and what ill actually need to buy to make this work. Thanks

I have read DIY led threads and I need help with what electrical parts I need to accumulate for the build. I understand I will probably need a couple drivers Meanwells to be exact. Going with Cree LEDS and the accessories needed for them ex.(heat sink), but then to my understanding if I want to make them auto dimmable like sunrise and sunset, then what other pieces of equipment or hardware do I need? I have read people mention an arduino. But I need more knowledge on functions of devices, capabilities, and what ill actually need to buy to make this work. Thanks

I have builted a driver for leds, to make it programmable i would use a plc so the voltage can vary automatically, i have not builded a led fixture yet. LED people come out from the woods and help out here

Any thoughts on the current design of my light?

Also any suggestions on "finishing" the top half so it could be safe to move around? I was considering just "building in" the top with hardboard secured to a small interior frame - just big enough to contain the wiring.

Last, how about "properly" wiring power into the ficture? Say I have the hardboard box built above...what's the correct way to enter the box with power and best way to secure the cable inside?

I'd also like wiring suggestions in general.....this works well, but it seems like there should be a much more efficient or otherwise better way to wire these up. (All sockets are wired in parallel.)

(Sorry for the "awesome" phtotos.)

The next iteration will actually be three "rails" of 16 bulbs each (vs two "rails" as in the photos), so that's going to be a lot of connections! (96!) Tips will be appreciated!

-Matt

Solder and shrink wrap, it will clean up real nice

Similar threads

- Replies

- 18

- Views

- 631

- Replies

- 19

- Views

- 529

- Replies

- 1

- Views

- 87

New Posts

-

Markings on Gem Tang I can only see at night?

- Latest: onlyreefers

-

Big swings of parameters after water change

- Latest: GlassMunky

-

-