- Joined

- Nov 14, 2018

- Messages

- 50

- Reaction score

- 17

Hello alll!

Not completely new to the hobby but you could still call me a newbie. Did a fresh 40gal tank install with lessons learned from failures of the past. One important factor for this setup being successful so far (knock-on-wood) is my terrible memory with topping off tanks. I've had a tendency to start a top off and forget to end it. I've seen some very conventional methods of using floats and such that all look great but I wanted to share my flavor with everyone.

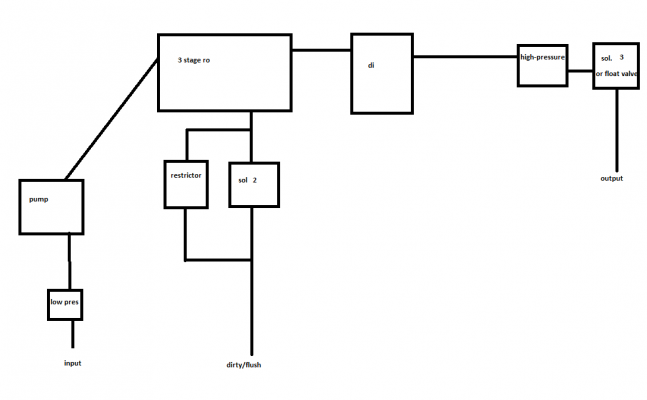

Some basic attributes:

With enough interest I'm willing to make it open source. I have a BOM, wiring diagram, and models for the 3D printables. I put the cost around $75 if you buy everything... Though I had most of this laying around.

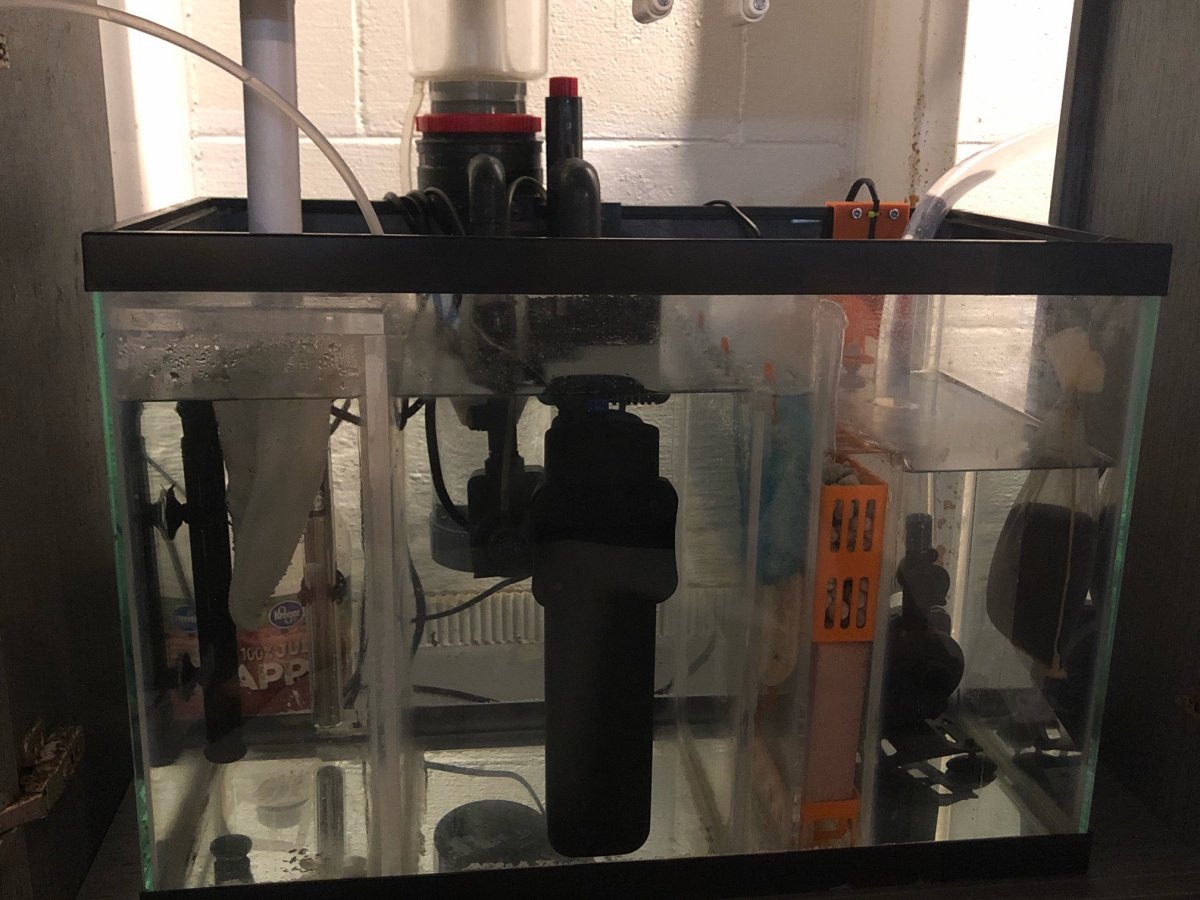

Full shot of fill-station

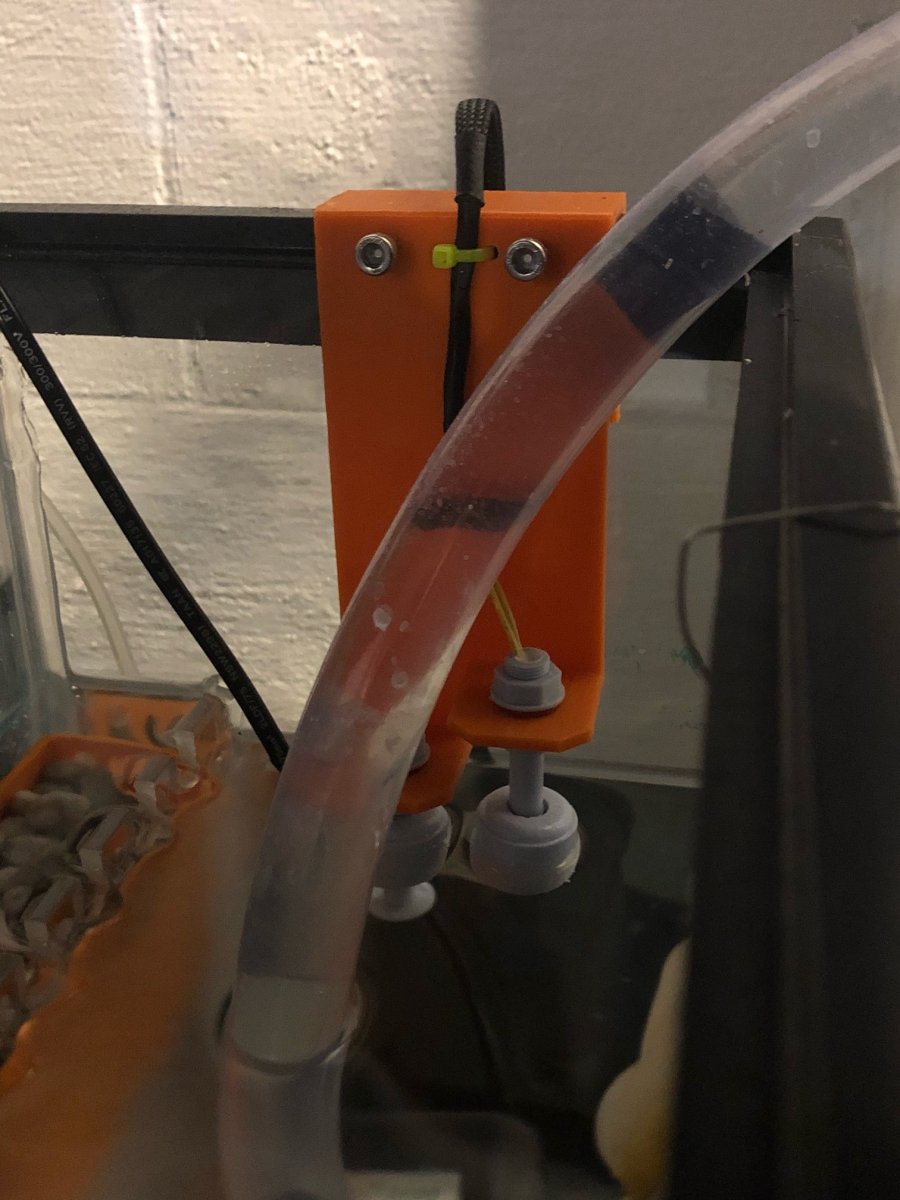

Close-up of enclosure

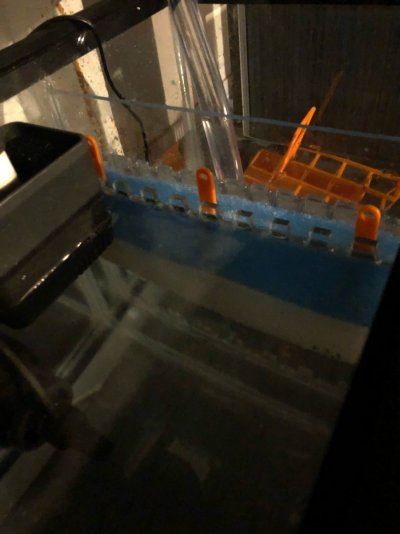

Close-up of digital float switches

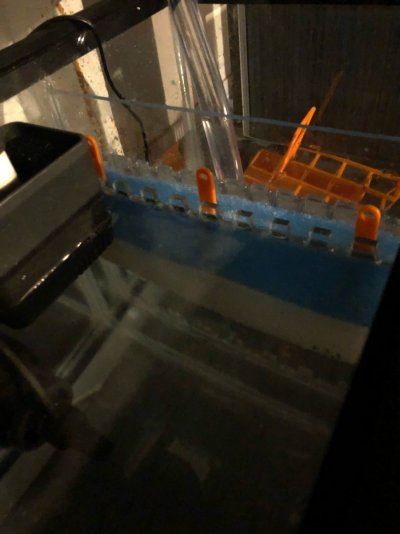

Full-shot of switches in sump

A look at the internals of the project box

Not completely new to the hobby but you could still call me a newbie. Did a fresh 40gal tank install with lessons learned from failures of the past. One important factor for this setup being successful so far (knock-on-wood) is my terrible memory with topping off tanks. I've had a tendency to start a top off and forget to end it. I've seen some very conventional methods of using floats and such that all look great but I wanted to share my flavor with everyone.

Some basic attributes:

- Arduino 2560 controlled

- Digital float switches (food safe)

- 1/4" water-line solenoid 12V

- Controlled (actuated) at water-source and not at the sump

- OLED read-out and debug screen

- Standard 1/4" water-fittings and valves

- 3D printed enclosure/project box

- Bypass loop allows for manual control when wanted - also in event of solenoid failure

With enough interest I'm willing to make it open source. I have a BOM, wiring diagram, and models for the 3D printables. I put the cost around $75 if you buy everything... Though I had most of this laying around.

Full shot of fill-station

Close-up of enclosure

Close-up of digital float switches

Full-shot of switches in sump

A look at the internals of the project box