- Joined

- May 6, 2017

- Messages

- 531

- Reaction score

- 284

Ok that's not fair you guys have some beautiful craftsmanship I your sumps

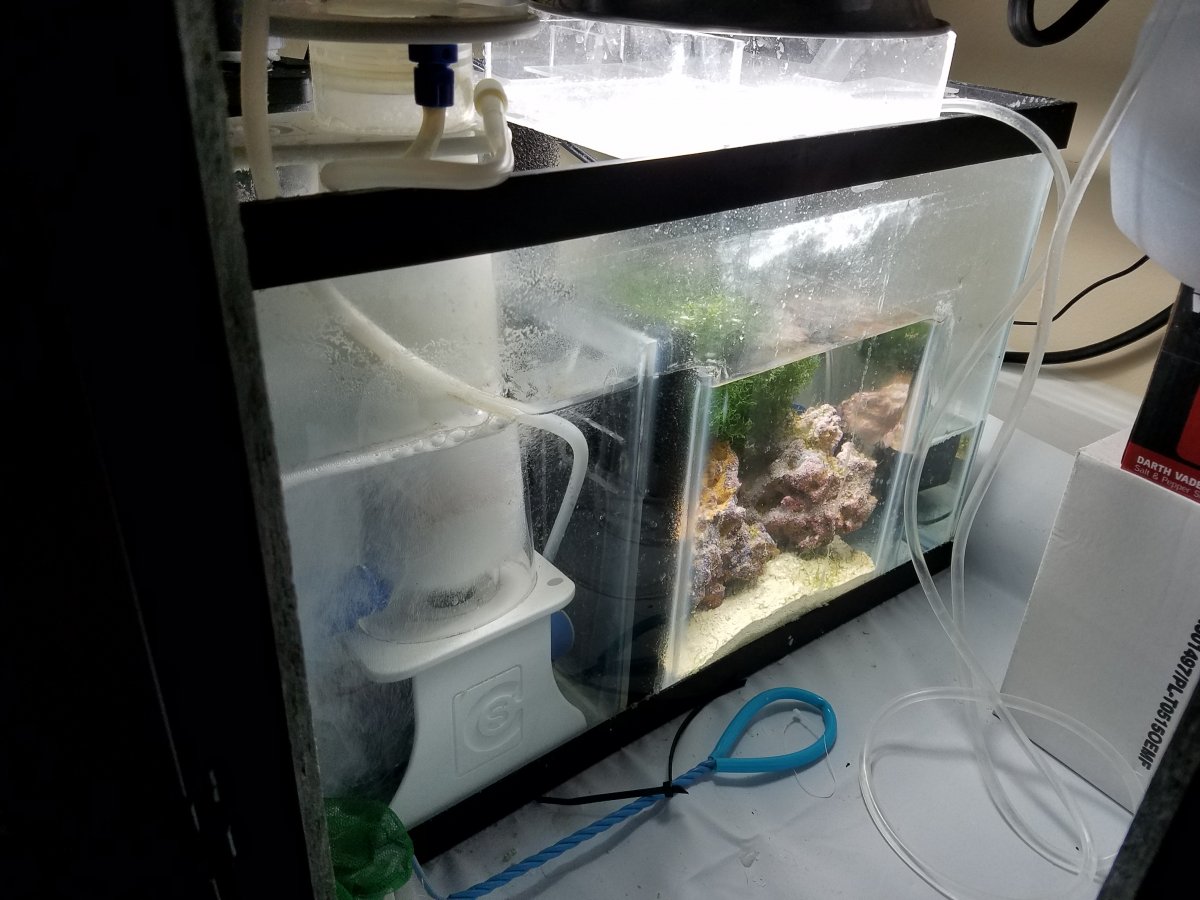

Mine is a 10 gallong glass tank with 1/4" acrylic siliconed on i had major size restrictions spitfire its a bit tight but i got everything in there

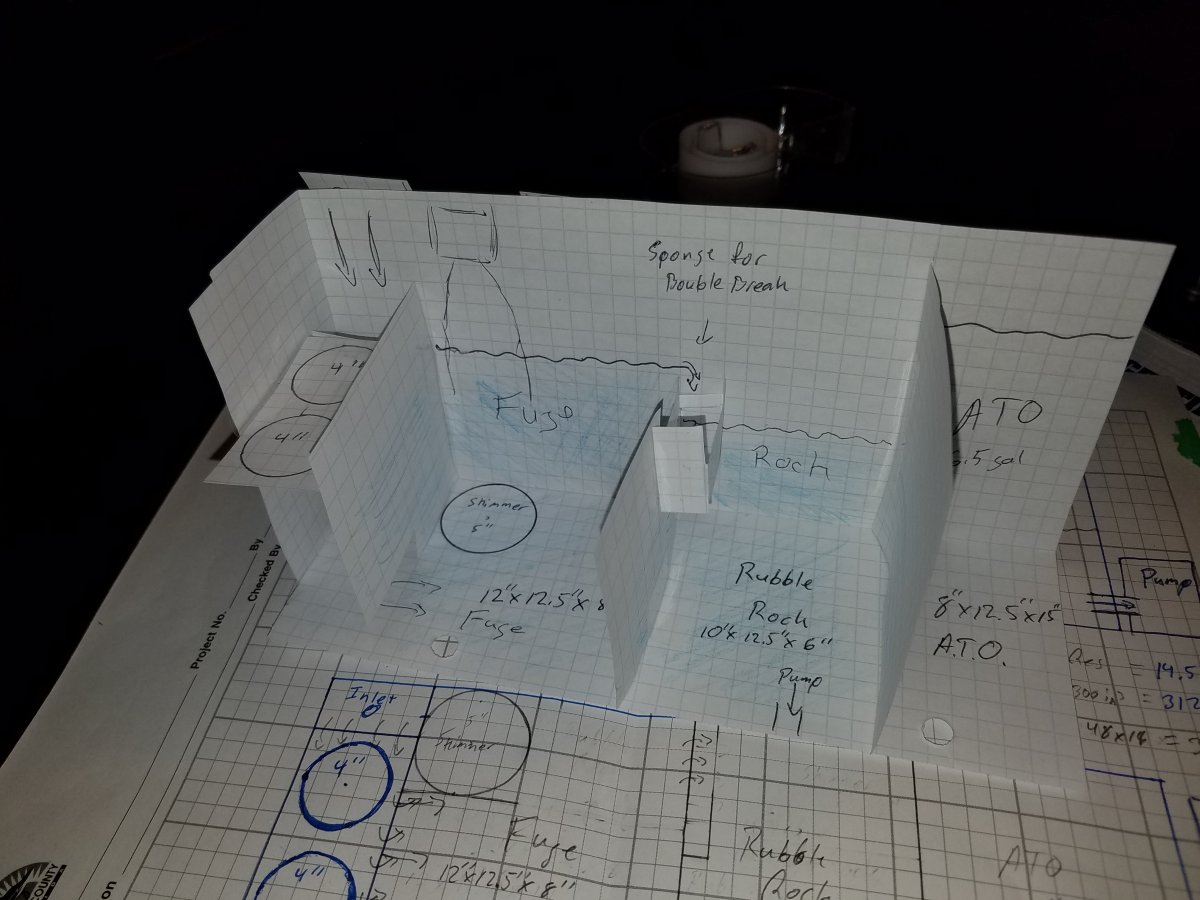

This is the design for my new 30 gallon sump on the 90 I'm setting up. But same style glass with acrylic

Mine is a 10 gallong glass tank with 1/4" acrylic siliconed on i had major size restrictions spitfire its a bit tight but i got everything in there

This is the design for my new 30 gallon sump on the 90 I'm setting up. But same style glass with acrylic