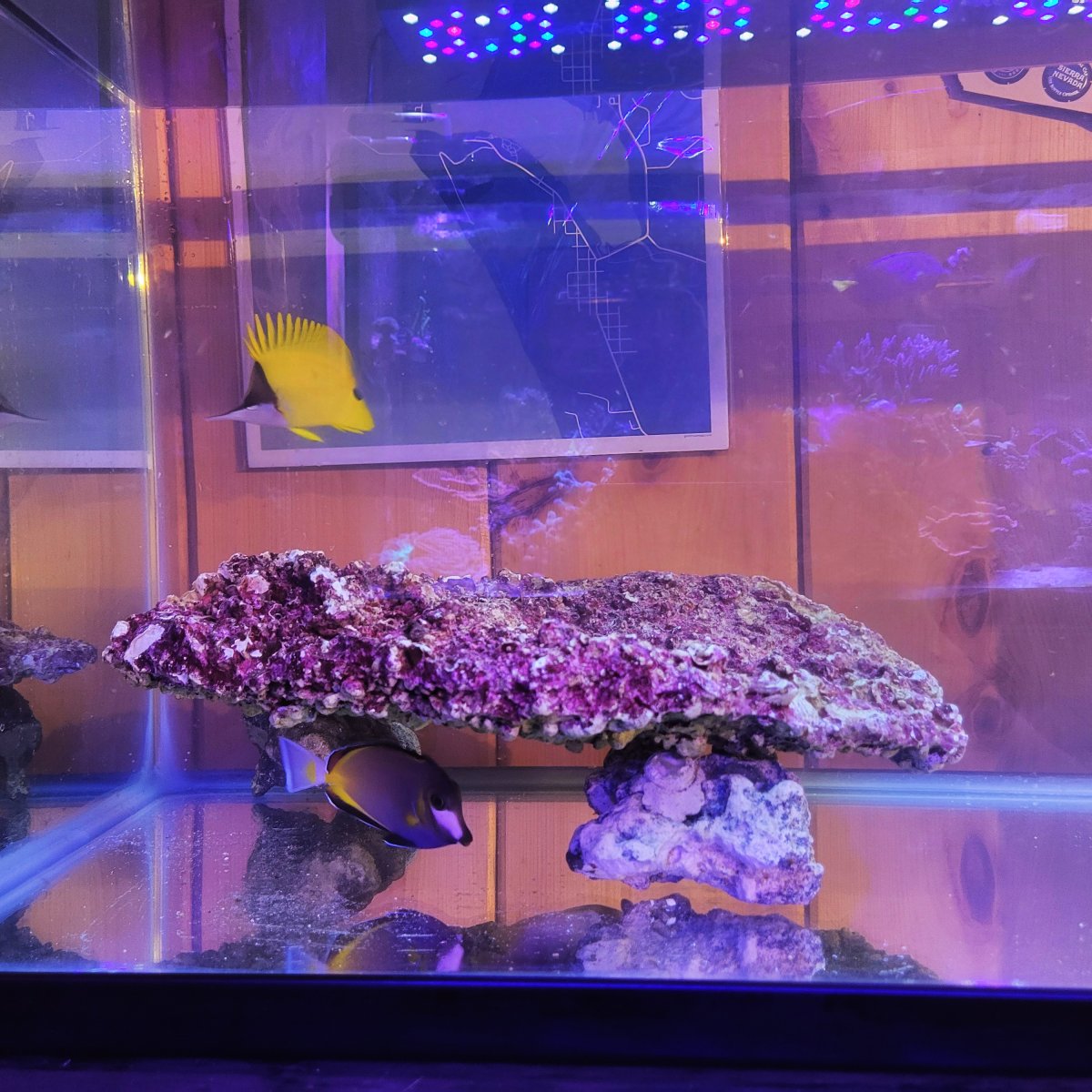

I am super excited! Picked up my 3'x7' 115gallon tank yesterday and going to start putting this togeather to be hooked to my main system for propagation and growout of mostly sps corals. Going to light it with reefbreeders photon fixtures. Still haven't figured out what way I'm going to do the plumbing just yet so I have to get that figured out then I can build the stand and start hooking up pipes!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Northernmichiganreef frag/grow out tank.

- Thread starter Tonycass12

- Start date

- Tagged users None

Bulkheads, drain strainers all ordered. Picked up a few fish that will be going in here to help keep things clean, ill probably transfer over 1 or 2 more tangs that are getting too big in my main tank as well. Just need to get ontop of building my stand.

Following along!

Looks like its about 1/8 of an inch thick @Harpo

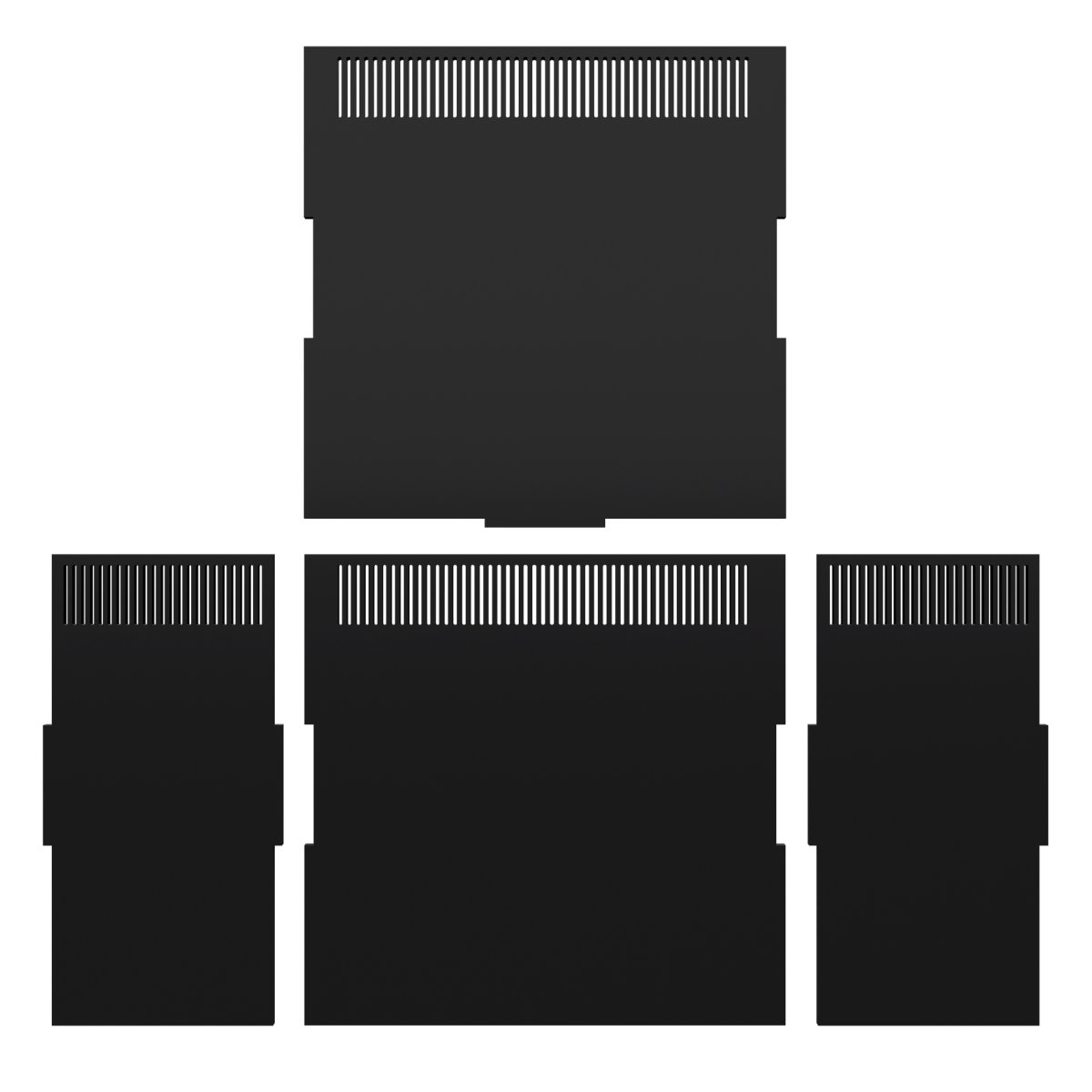

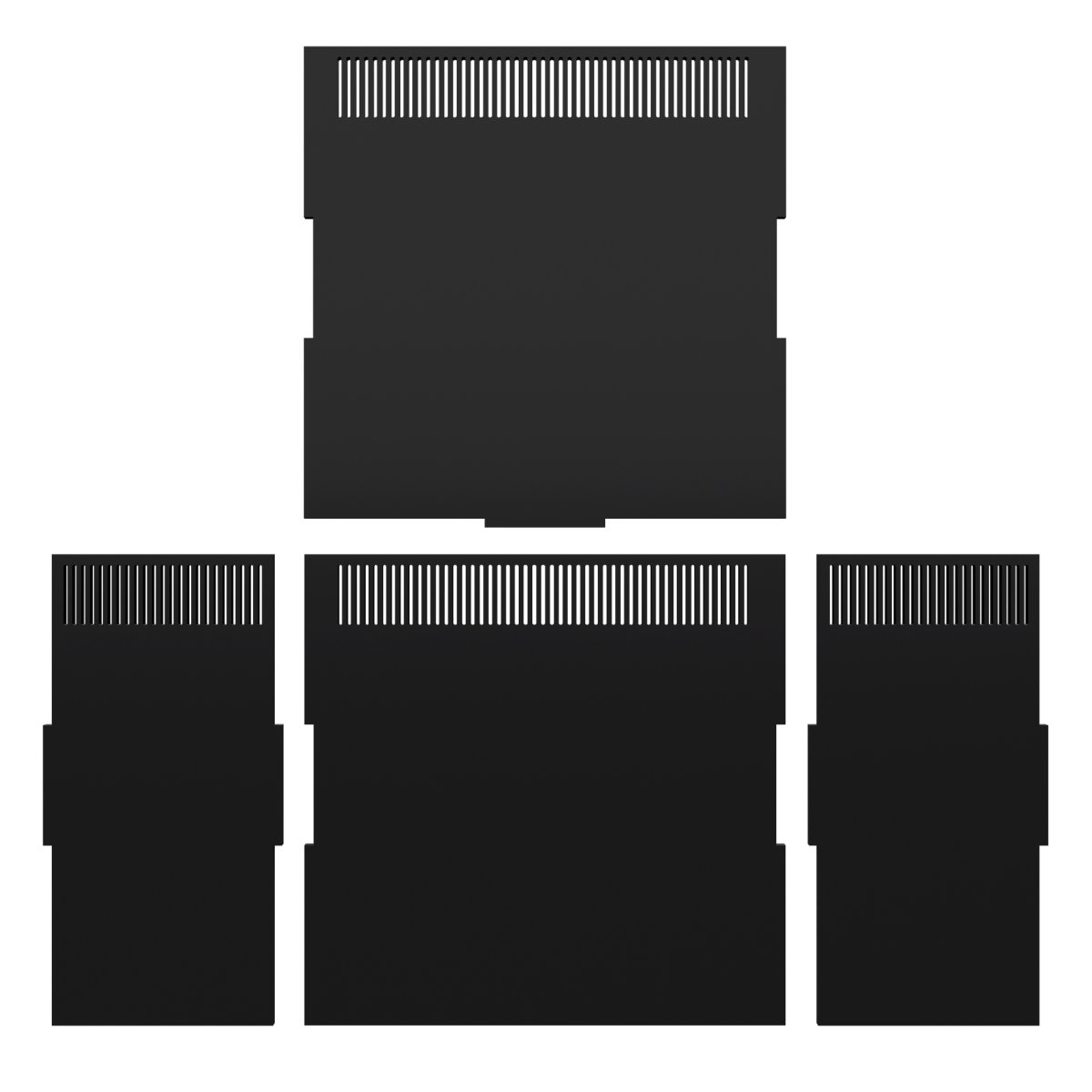

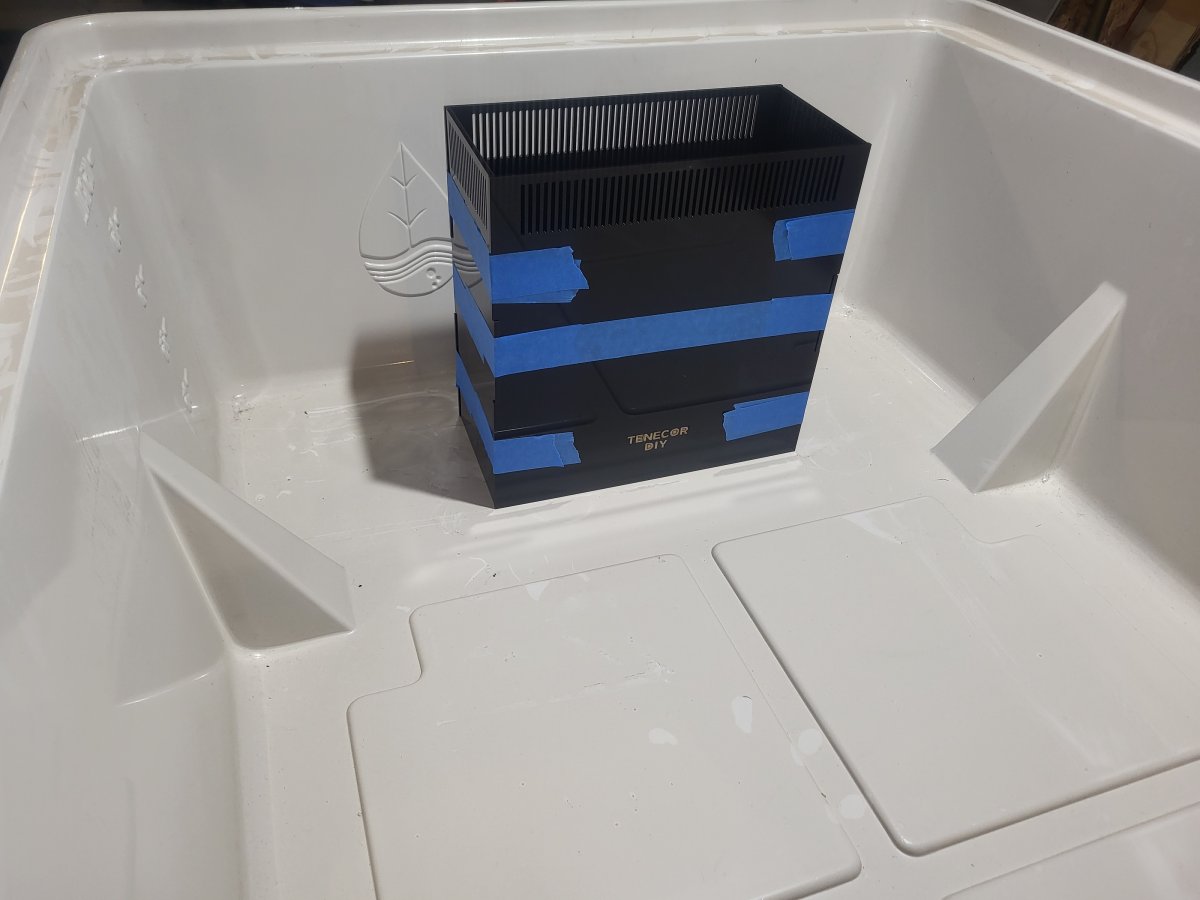

Slow progress but finally have the stand about 90% togeather so I could do a test fit. Im going to be trying my hand at putting togeather a pre cut nano tank from tenecore soon and I figured since I have the solvent I might as well try making an overflow box for this setup as well. So I've decided on 3 1"drains that I will box around with black acrylic. I should be able to bond the overflow box to this tank without an issue.

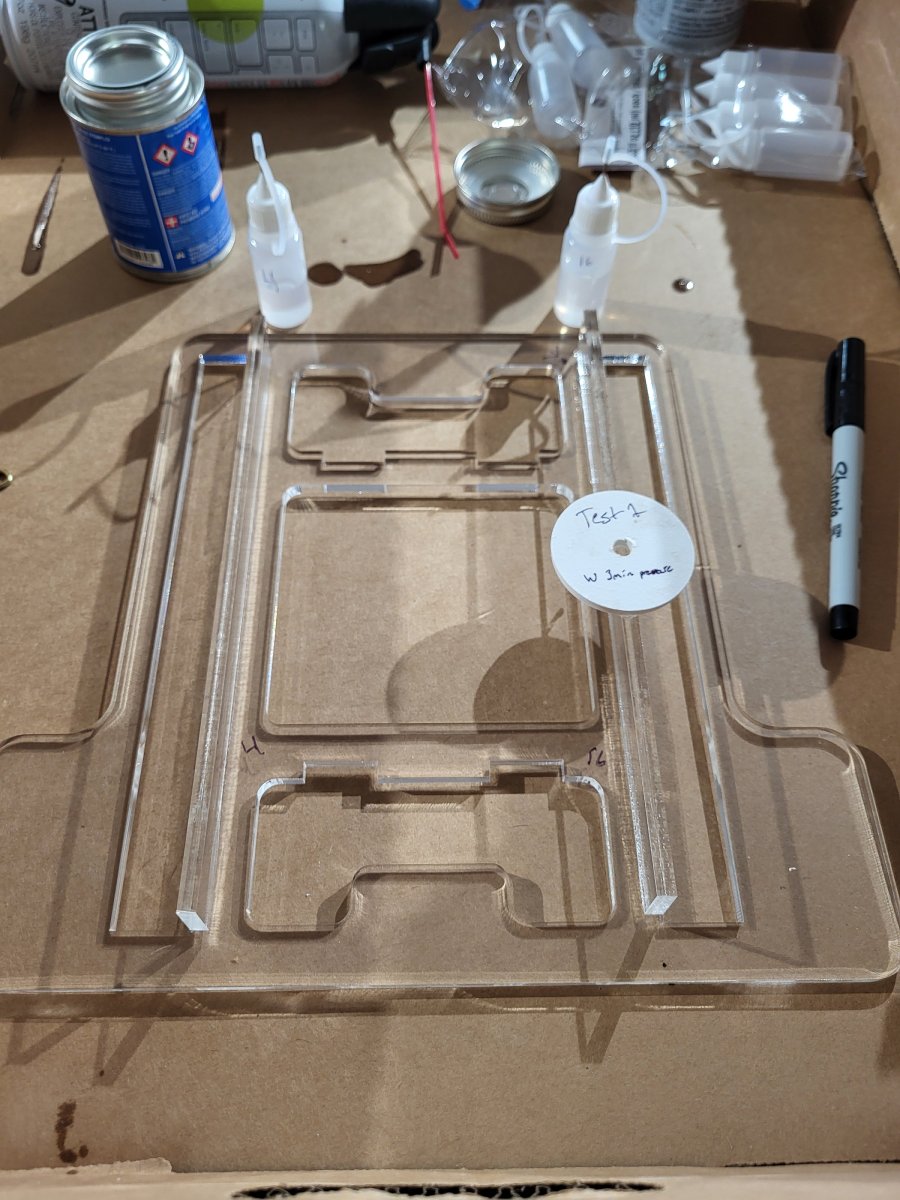

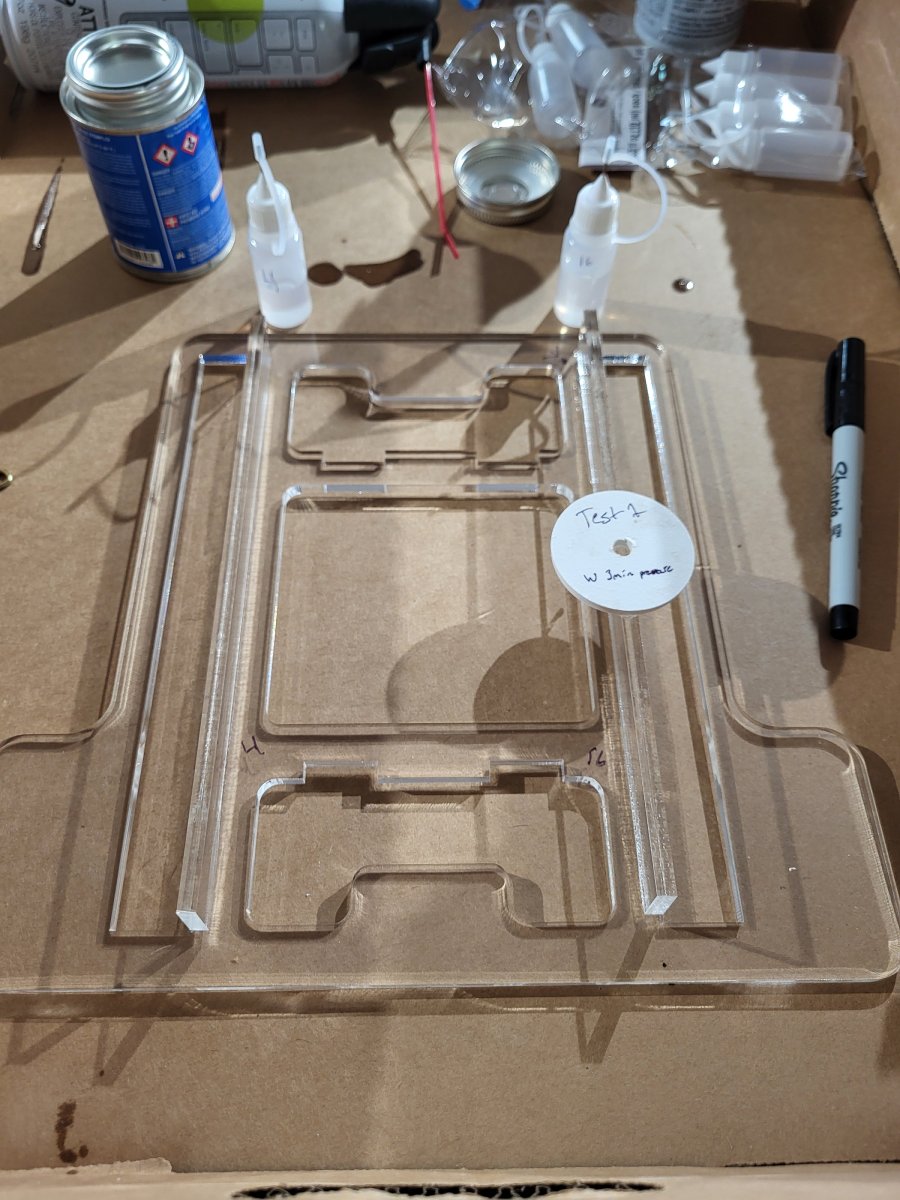

Well plan was to cut and build my own overflow for this. I got involved with the tenecor DIY nano build and figured since I'm already getting into the acrylic bonding/welding I could probably do this as well. After asking what saw blade is best for cutting acrylic @Tenecor Aquariums reached out and and a few questions later....

Tenecor will be cutting the panels for me and I will do final assembly. This is awesome and probably 10x better of a finish then I would get without shelling out a bunch of cash and time to get blades and build jigs for all the cuts. The overflow will house 3 1" drains for redundancy return plumbing will just come in over the side of the tank. I think I've got final placement figured out. I may start framing a room in around the tank after I get back from a little wilderness adventure this next week.

Tenecor will be cutting the panels for me and I will do final assembly. This is awesome and probably 10x better of a finish then I would get without shelling out a bunch of cash and time to get blades and build jigs for all the cuts. The overflow will house 3 1" drains for redundancy return plumbing will just come in over the side of the tank. I think I've got final placement figured out. I may start framing a room in around the tank after I get back from a little wilderness adventure this next week.

Here is your link to your OF box. >>> https://www.tenecoraquariums.com/pr...t-self-assembly-overflow-box-1000-gph-12x6x12

Well plan was to cut and build my own overflow for this. I got involved with the tenecor DIY nano build and figured since I'm already getting into the acrylic bonding/welding I could probably do this as well. After asking what saw blade is best for cutting acrylic @Tenecor Aquariums reached out and and a few questions later....

Tenecor will be cutting the panels for me and I will do final assembly. This is awesome and probably 10x better of a finish then I would get without shelling out a bunch of cash and time to get blades and build jigs for all the cuts. The overflow will house 3 1" drains for redundancy return plumbing will just come in over the side of the tank. I think I've got final placement figured out. I may start framing a room in around the tank after I get back from a little wilderness adventure this next week.

If you have any problems with the assembly, please read our "Do Over" Guarantee. This tab and open notch assembly is new and you are the first one to get this design. We have another design, the tab and CLOSED notch which is proven to be a solid choice. Either way, we will work with you. Tenecor will be adding dozens of new DIY products such as frag tanks. media caddies and ATO reservoirs such as the one

below. Happy Reefing!

A whole family of DIY ATO Reservoirs

DIY Media Caddies too. This one is for the IM Fusion Series.

All ordered up, thank you guys again this is awesome I can't wait to have this system up and running.Here is your link to your OF box. >>> https://www.tenecoraquariums.com/products/tenecor®-diy-tower-mount-self-assembly-overflow-box-1000-gph-12x6x12

If you have any problems with the assembly, please read our "Do Over" Guarantee. This tab and open notch assembly is new and you are the first one to get this design. We have another design, the tab and CLOSED notch which is proven to be a solid choice. Either way, we will work with you. Tenecor will be adding dozens of new DIY products such as frag tanks. media caddies and ATO reservoirs such as the one

below. Happy Reefing!

A whole family of DIY ATO Reservoirs

Making progress this weekend

All welded up. Now we get to cut some holes for bulkheads.

Wow, nice work on it. What kind of issues if any did you face with the tabs? Seriously, you do nice work.All welded up. Now we get to cut some holes for bulkheads.

Thank you! No issues, just took my time and made sure the tape was tight enough that the panels weren't shifting especially near the tabs. I just masking taped a contractors square the the bottom corner tight as well to square the box up. After laying each bead of weldon I gave it ample time to set so I was positive I wouldnt be shifting panels before they were solid. The tabs left small gaps on the outside less then 1mm but I just used a bottle with a syringe tip and got the weldon right down into any gaps.

Wow, nice work on it. What kind of issues if any did you face with the tabs? Seriously, you do nice work.

No turning back now.

Here is a little side profile of the tub thickness

Here is a little side profile of the tub thickness

Plan is to weld the overflow on tomorrow. If everything works out well that will put it up for a water test by the end of the week. Going to pick up some spa flex and a couple of ball valves so I can get the plumbing done before the weekend.

Well days later then I wanted but its attached. Things got delayed because i decided to reach out to weldon with some questions and run a test beforehand. I was happy with my test chunk I did to see how the acrylic and tub ABS would bond with weldon 16. An weldon got back to me saying 16 is the proper product for the application.

Overflow install.

I applied a coat of weldon 16 to the base of the overflow as quick as I could then flipped it and dropped it in place. I then ran around the exterior and the interior seam on the base with another quick coat of weldon to make sure the bond would be solid all the way around. One of the reps for weldon advised when bonding these two different materials to give it at least 72 hrs before running a test. so here we go, a few more days and maybe some water... this project is quickly growing and we've decided to help deal with the humidity in the house this area will be getting walled in and have a doorway entering into the room where my main display is located.

Overflow install.

I applied a coat of weldon 16 to the base of the overflow as quick as I could then flipped it and dropped it in place. I then ran around the exterior and the interior seam on the base with another quick coat of weldon to make sure the bond would be solid all the way around. One of the reps for weldon advised when bonding these two different materials to give it at least 72 hrs before running a test. so here we go, a few more days and maybe some water... this project is quickly growing and we've decided to help deal with the humidity in the house this area will be getting walled in and have a doorway entering into the room where my main display is located.

Actually glad I ran across this thread. I was thinking about doing something similar. Talk about synchronicity. Keep us updated! I'll be following alongWell days later then I wanted but its attached. Things got delayed because i decided to reach out to weldon with some questions and run a test beforehand. I was happy with my test chunk I did to see how the acrylic and tub ABS would bond with weldon 16. An weldon got back to me saying 16 is the proper product for the application.

Overflow install.

I applied a coat of weldon 16 to the base of the overflow as quick as I could then flipped it and dropped it in place. I then ran around the exterior and the interior seam on the base with another quick coat of weldon to make sure the bond would be solid all the way around. One of the reps for weldon advised when bonding these two different materials to give it at least 72 hrs before running a test. so here we go, a few more days and maybe some water... this project is quickly growing and we've decided to help deal with the humidity in the house this area will be getting walled in and have a doorway entering into the room where my main display is located.

Wow, that's good to know that Weldon 16 will bond acrylic and ABS.

Similar threads

- Replies

- 7

- Views

- 411

- Replies

- 2

- Views

- 110

TOP 10 Trending Threads

- Replies

- 52

- Views

- 581

-

- Poll

- Replies

- 23

- Views

- 241

- Replies

- 27

- Views

- 398

-

- Poll

- Replies

- 32

- Views

- 460

- Replies

- 54

- Views

- 1,133

- Replies

- 64

- Views

- 555

- Question

- Replies

- 65

- Views

- 699

- Replies

- 36

- Views

- 411

- Replies

- 31

- Views

- 426

New Posts

-

SBB - AFTERPARTY SALE- 3 day event 1750 corals. Our Largest sale ever!

- Latest: NatanylJames

-

-