ATS Description

I've been trying out a DIY "SURF"-style algae scrubber for more than a year, but its nutrient export doesnt keep up with my feeding, so I want to give the algae scrubbing method a "last chance"... Now I've started making myself a quality waterfall style ATS. Instead of just buying a COTS product, I wanted to make my own small footprint scrubber and replicate many features found in other ATS designs, and maybe add one or two myself...

Scrubber features

I'm trying to incoperate the following features into my ATS... (Most are from the Turbo ATS).

Coast to coast screen

As most ATS designs I go with the Darice brand plastic canvas #7 count mesh screen. The algae screen will go from one end of the box to the other, ie "coast to coast".

Lightning

The ATS will use a mix of 660-670 nm red and 420 nm hyper violet LED. The screen will be lit from both sides by a grand total of 48 red LEDs and 18 violet LED's mounted on two 300 x 200 mm aluminum heatsinks.

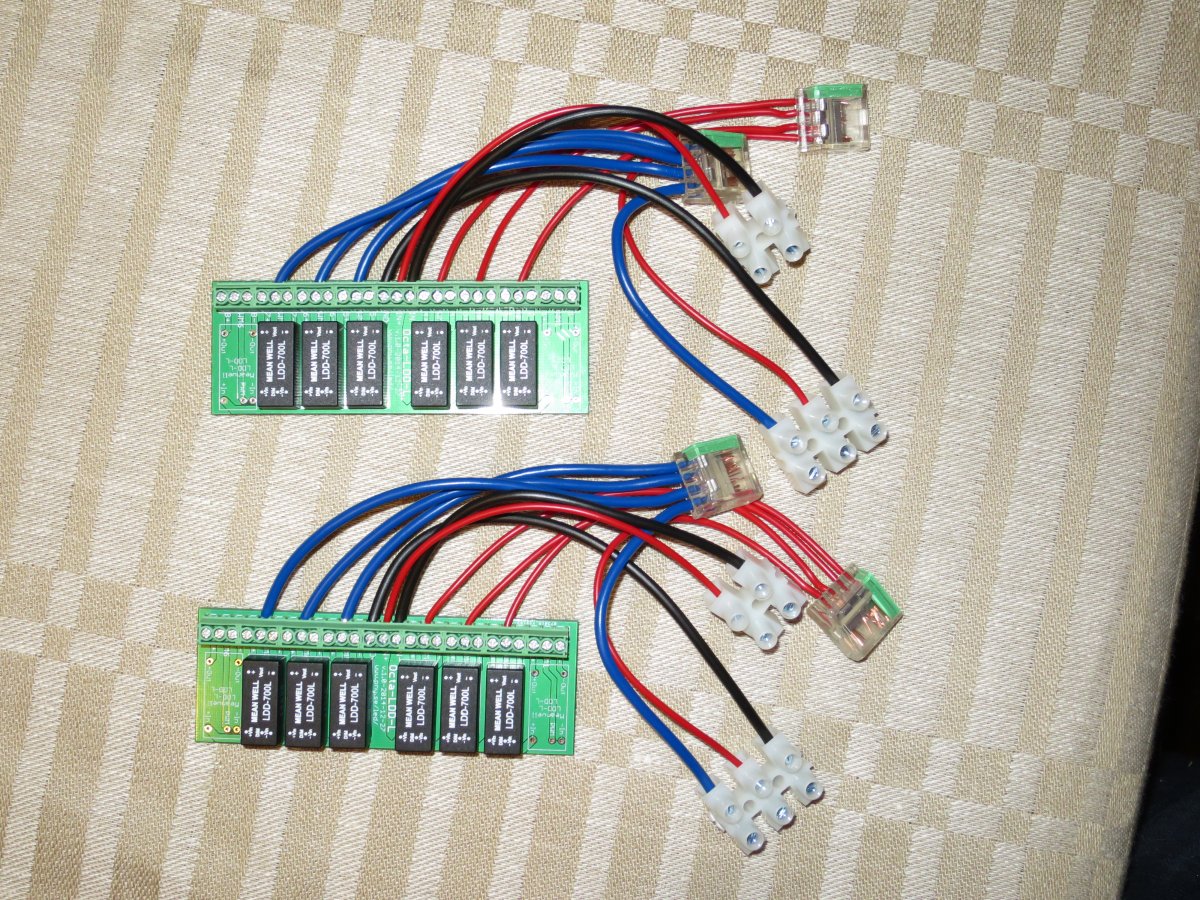

The LEDs will be powered by a 24V Meanwell waterproof powersupply and be driven by a number of Meanwell LDD-700L constant current circuits mounted on a PCB I designed a few years ago.

Lightning are very importing so I decided to go for named quality LEDs:

Luxeon LED, 2.2 V, 700 mA, LXM3-PD01-0300, BIN Code W

Steves LED Hyper violet 3.0, 3.7 V, 700mA

Two potentiometers will control the red and violet color dimming. An Arduino controller will perform potentiometer reading and output PWM signals. Also, it would be a nice feature to let the controller display the intensity percentage value for each of the two control channels. The Arduino controller will be powered from a 24V to 12V DC/DC converter.

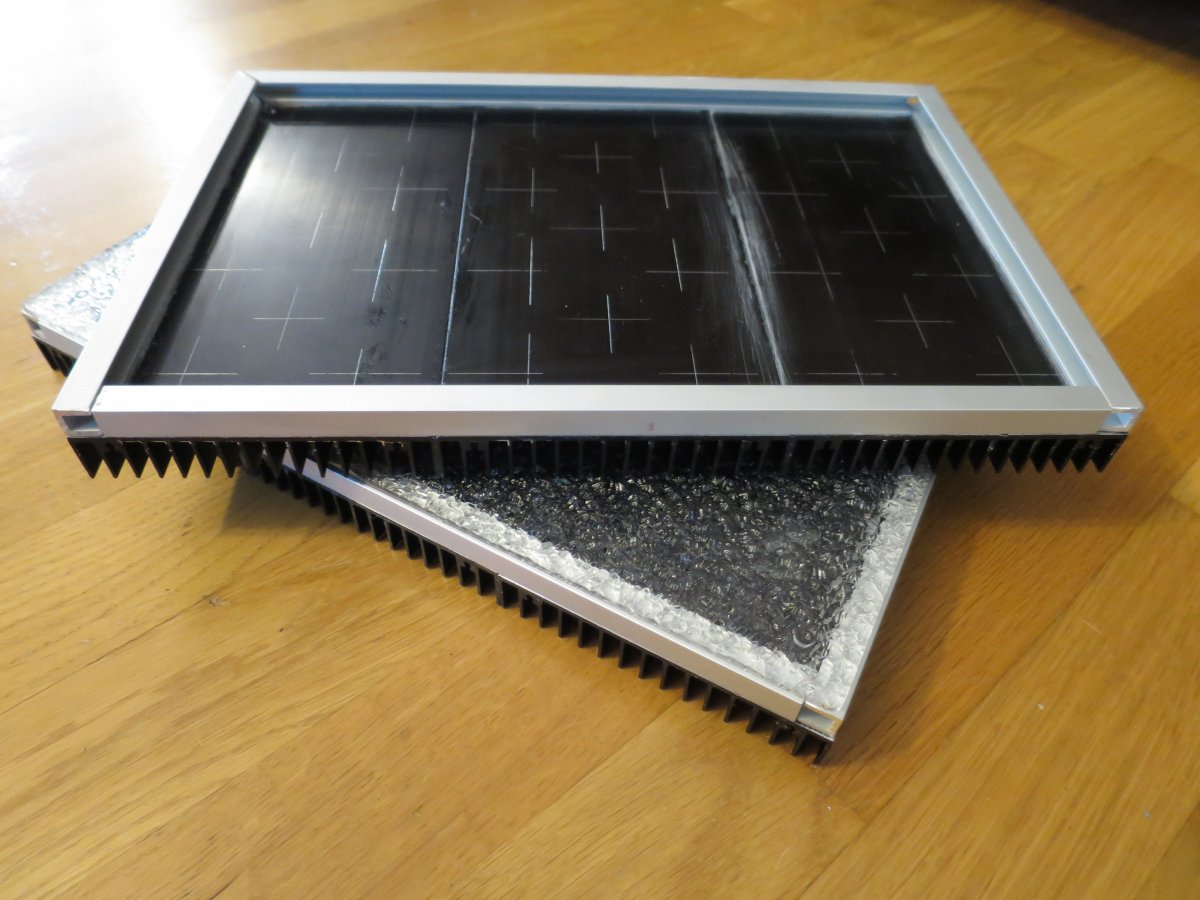

I could not get hold of heatsinks in the size I needed, therefore my 300 x 200 mm heatsink consists of 3 pcs mounted together. Additional aluminum profiles mounted as a frame around the perimeter of the heatsinks will ensure the spacing between the LEDs and a prismatic diffuser screen. The diffuser screen helps to produce an even light on the algae screen.

Growth chamber

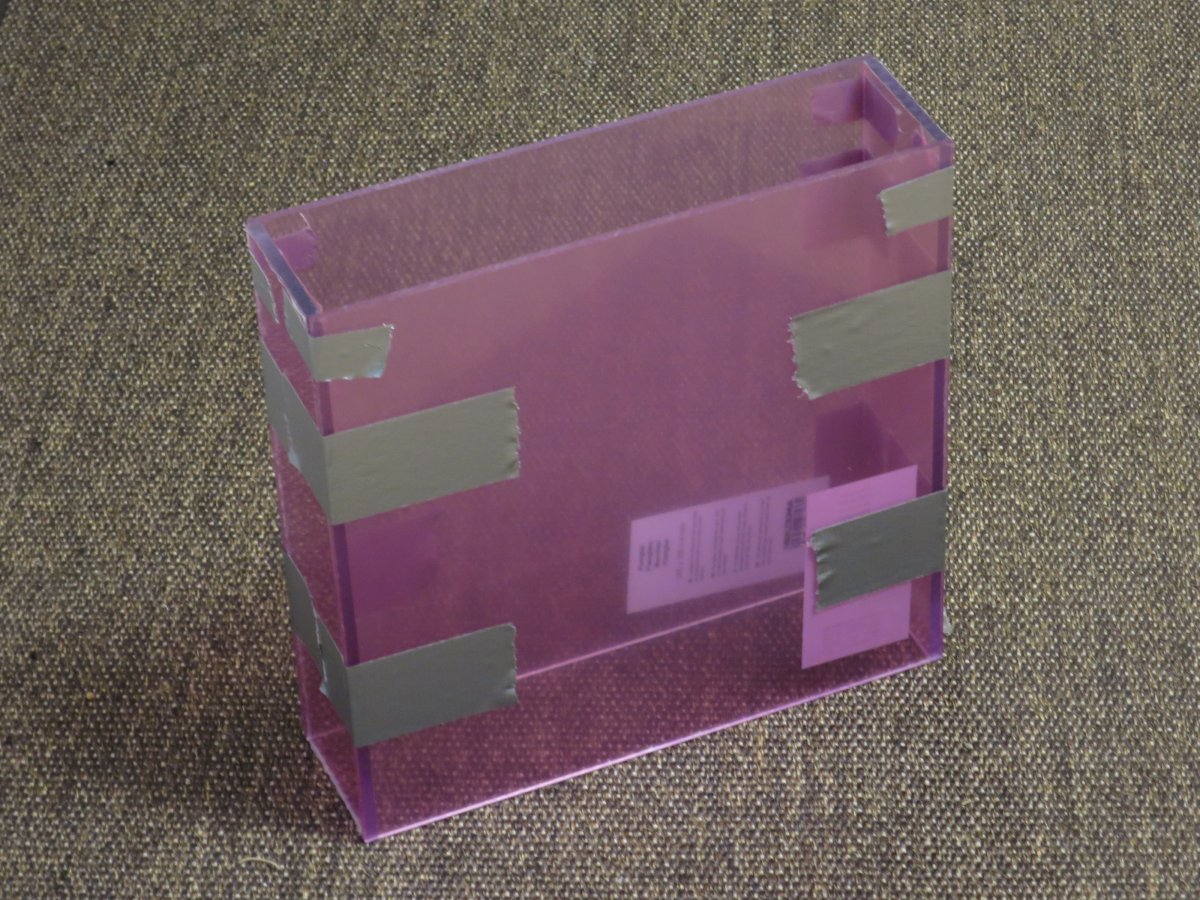

The ATS will have a classic fixed growth chamber made from clear acryllic sheets and have a viewing window on one short end. I will have to keep the growth chamber

design simple, since my tools for working with acryllic is very limited.

Slot pipe

To be decided... I have not decided if I should use a standard slot pipe or try to minimize height requirement by building a my own square pipe with integrated light blockers.

False bottom

The exact design of the false bottom is to be defined...

ATS System Plumbing

The ATS will initially be fed by its own water pump. In the future I might connect it to the manyfold on my return pump, but I'm not sure I can spare the amount of flow the ATS need so I might as well keep it on its own pump. The water from my return plumbing is not really an option either, since its already used to feed my skimmer and Rollermat mechanical filer.

Build process

Sourcing materials from the internet takes a a lot of time, but the delivery times give me the opportunity to think more about the design... So far, I've sourced about 2/3 of the materials, I've cut some of the acrylics and glued the heatsinks together. Now I'm Waiting for LEDs and some more aluminum profiles.

Sourced so far:

* PVC pipe/fittings, 25 mm and 32 mm

* Prismatic diffuser screen, 2 pcs 300 x 210 mm

* Plastic Canvas Screen, Darice #7 mesh

* Black and transparent acrylic sheets

* Aluminum heatsink, 6 pcs 200 x 100 x 18mm

* LED power supply 24V/10A 240W, MeanWell HLG-240H-24A

* DIY LED drivers, 700 mA

* Red LED's 660-670 nm, Philips Luxeon ES Deep Red 3W

* Violet LEDs, Steves LED Hyper violet 3.0

* Arduino controller, display and potentiometers for PWM dimming.

* Aluminum profiles for light fixtures

Not sourced yet:

* Arduino power supply (24V to 12V converter)

* Power supply contacts

* More PVC fittings for drains

* Water pump

Photos

Above: Light fixtures waiting for LED...

Above: DIY LED Drivers

Above: LED drivers wired for power and PWM input.

Above: Trying out a growth chamber, (protecting plastic makes them look pink).

Lets hope the remaining parts will arrive soon, so I can continue my build...

I've been trying out a DIY "SURF"-style algae scrubber for more than a year, but its nutrient export doesnt keep up with my feeding, so I want to give the algae scrubbing method a "last chance"... Now I've started making myself a quality waterfall style ATS. Instead of just buying a COTS product, I wanted to make my own small footprint scrubber and replicate many features found in other ATS designs, and maybe add one or two myself...

Scrubber features

I'm trying to incoperate the following features into my ATS... (Most are from the Turbo ATS).

- Compact design, about 35 x 14.5 x 30 cm (LxWxH), including LED heatsink

- ~100 square inch screen, equals L8 size

- Low voltage, 24V power supply for safety

- Coast to coast algae screen to maximize screen length

- Red and violet lights with individual color channel dimming

- Side viewing window to enable easy view of growth

- Removable false bottom to prevent the algae growth to block the drains

- Multiple drain design for safe and silent operation with drain tuning

- Additional emergency drain to prevent flooding

- Light blocker around the slot to keep the flow out area clear of algae

- Slot pipe brackets that fixates the slot in a straight down pointing direction, ensuring that the flow stays as even as possible on both sides of the screen.

- Large flow capacity

- Tight fit around the light fixtures and a light blocking lid to prevent algae to grow everywhere in the sump area

Coast to coast screen

As most ATS designs I go with the Darice brand plastic canvas #7 count mesh screen. The algae screen will go from one end of the box to the other, ie "coast to coast".

Lightning

The ATS will use a mix of 660-670 nm red and 420 nm hyper violet LED. The screen will be lit from both sides by a grand total of 48 red LEDs and 18 violet LED's mounted on two 300 x 200 mm aluminum heatsinks.

The LEDs will be powered by a 24V Meanwell waterproof powersupply and be driven by a number of Meanwell LDD-700L constant current circuits mounted on a PCB I designed a few years ago.

Lightning are very importing so I decided to go for named quality LEDs:

Luxeon LED, 2.2 V, 700 mA, LXM3-PD01-0300, BIN Code W

Steves LED Hyper violet 3.0, 3.7 V, 700mA

Two potentiometers will control the red and violet color dimming. An Arduino controller will perform potentiometer reading and output PWM signals. Also, it would be a nice feature to let the controller display the intensity percentage value for each of the two control channels. The Arduino controller will be powered from a 24V to 12V DC/DC converter.

I could not get hold of heatsinks in the size I needed, therefore my 300 x 200 mm heatsink consists of 3 pcs mounted together. Additional aluminum profiles mounted as a frame around the perimeter of the heatsinks will ensure the spacing between the LEDs and a prismatic diffuser screen. The diffuser screen helps to produce an even light on the algae screen.

Growth chamber

The ATS will have a classic fixed growth chamber made from clear acryllic sheets and have a viewing window on one short end. I will have to keep the growth chamber

design simple, since my tools for working with acryllic is very limited.

Slot pipe

To be decided... I have not decided if I should use a standard slot pipe or try to minimize height requirement by building a my own square pipe with integrated light blockers.

False bottom

The exact design of the false bottom is to be defined...

ATS System Plumbing

The ATS will initially be fed by its own water pump. In the future I might connect it to the manyfold on my return pump, but I'm not sure I can spare the amount of flow the ATS need so I might as well keep it on its own pump. The water from my return plumbing is not really an option either, since its already used to feed my skimmer and Rollermat mechanical filer.

Build process

Sourcing materials from the internet takes a a lot of time, but the delivery times give me the opportunity to think more about the design... So far, I've sourced about 2/3 of the materials, I've cut some of the acrylics and glued the heatsinks together. Now I'm Waiting for LEDs and some more aluminum profiles.

Sourced so far:

* PVC pipe/fittings, 25 mm and 32 mm

* Prismatic diffuser screen, 2 pcs 300 x 210 mm

* Plastic Canvas Screen, Darice #7 mesh

* Black and transparent acrylic sheets

* Aluminum heatsink, 6 pcs 200 x 100 x 18mm

* LED power supply 24V/10A 240W, MeanWell HLG-240H-24A

* DIY LED drivers, 700 mA

* Red LED's 660-670 nm, Philips Luxeon ES Deep Red 3W

* Violet LEDs, Steves LED Hyper violet 3.0

* Arduino controller, display and potentiometers for PWM dimming.

* Aluminum profiles for light fixtures

Not sourced yet:

* Arduino power supply (24V to 12V converter)

* Power supply contacts

* More PVC fittings for drains

* Water pump

Photos

Above: Light fixtures waiting for LED...

Above: DIY LED Drivers

Above: LED drivers wired for power and PWM input.

Above: Trying out a growth chamber, (protecting plastic makes them look pink).

Lets hope the remaining parts will arrive soon, so I can continue my build...