- Joined

- Oct 8, 2018

- Messages

- 16

- Reaction score

- 41

Hi all,

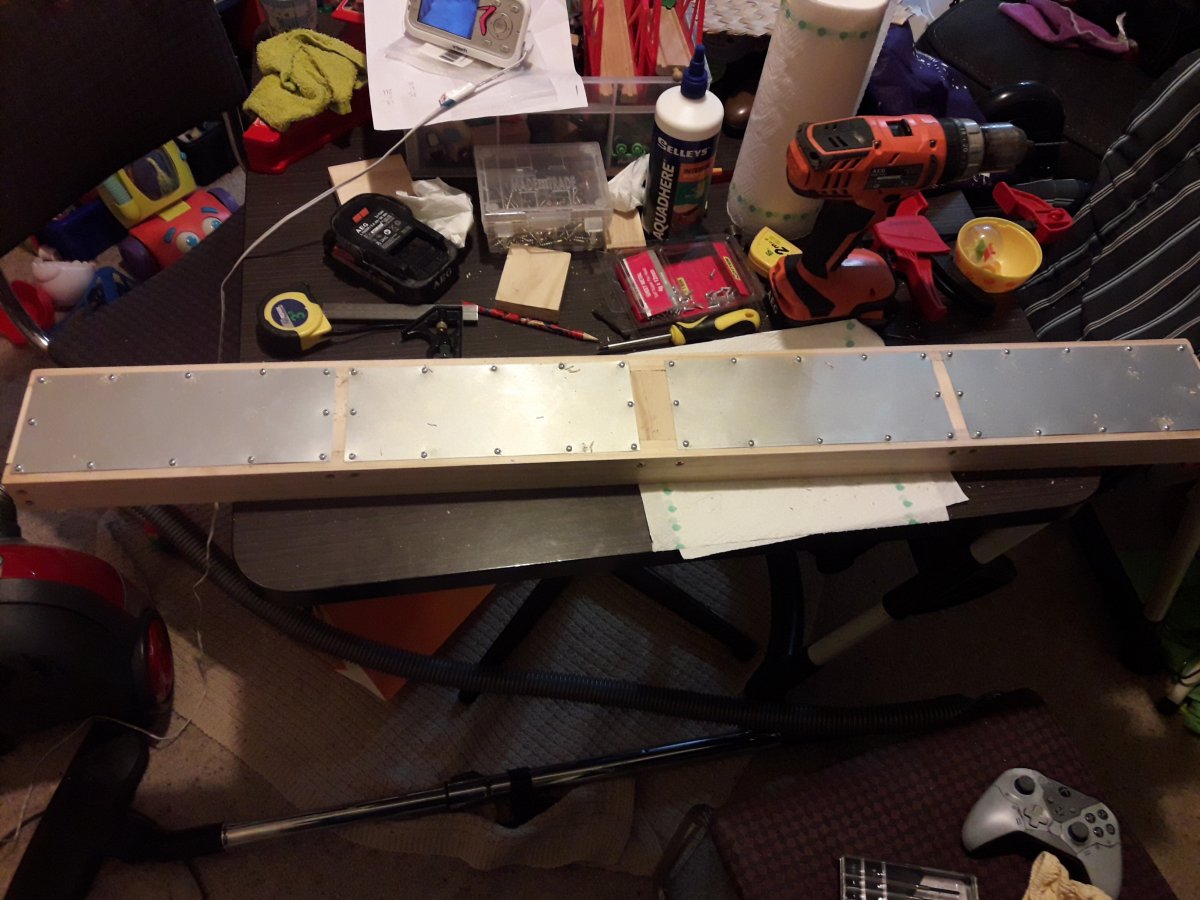

Yesterday, got board and started to make an LED light unit to go with a cabinet I made a few months back for one of my fresh water tanks... but making sure it can be used for reef in the future.

Made the frame last night, and planning to solder the LED's on tonight.

Photo's of what I've done so far, plus a shot of the cabinet before I put the tank into it. Don't mind the mess, the kids tried to take over the cabinet the second I built it.

Yesterday, got board and started to make an LED light unit to go with a cabinet I made a few months back for one of my fresh water tanks... but making sure it can be used for reef in the future.

Made the frame last night, and planning to solder the LED's on tonight.

Photo's of what I've done so far, plus a shot of the cabinet before I put the tank into it. Don't mind the mess, the kids tried to take over the cabinet the second I built it.