Beautiful tank! Looking forward to watching the process.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rsumner's 450gal Home Office Reef

- Monster Build

- Thread starter rsumner

- Start date

- Tagged users None

I’m still in the plumbing phase of my build. I originally purchased standard Sch40 pipe locally and painted it charcoal gray to match Sch80 pipe but without sacrificing flow. I got all my drain runs glued and painted:

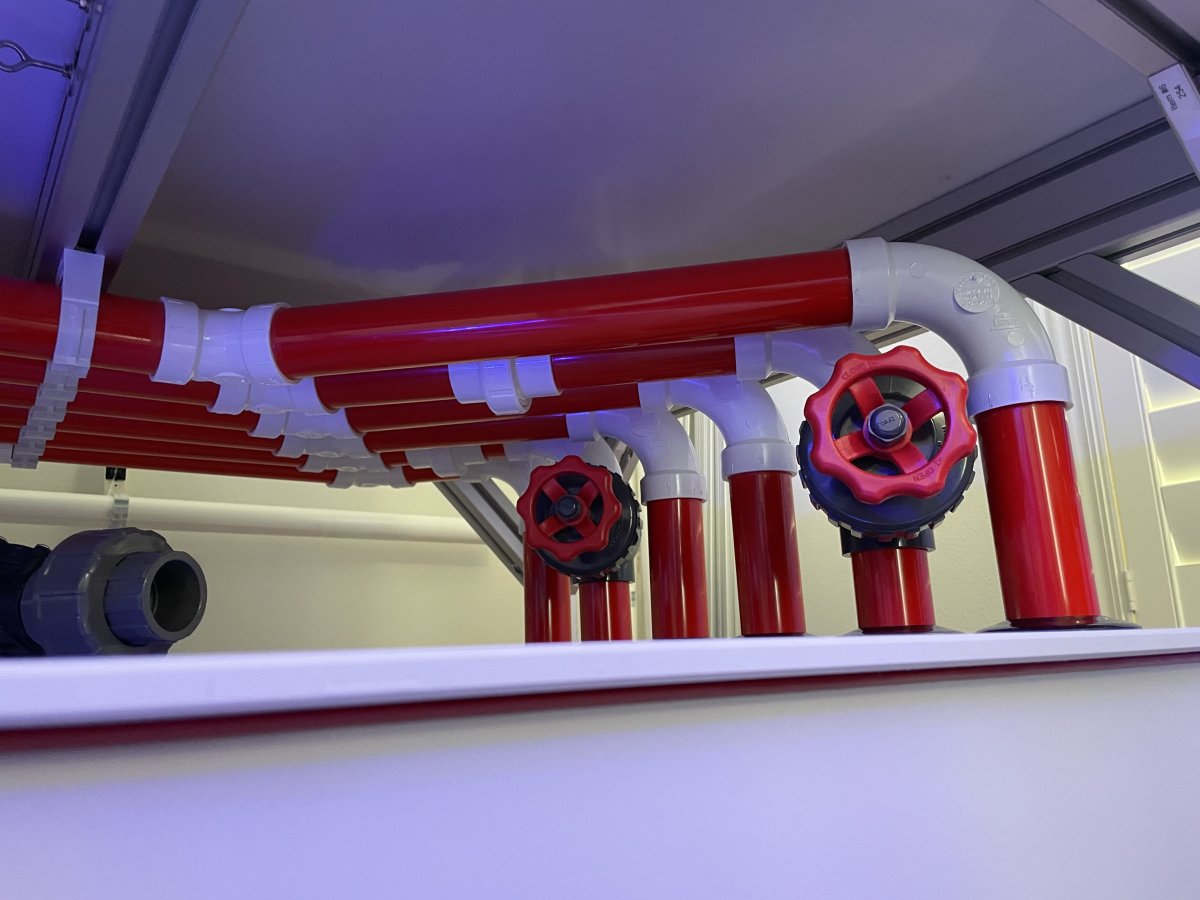

It took me weeks to paint it due to the size, but wasn’t happy with the outcome. It’s really hard to get an even coat of paint on these long pipes. I ripped it all out yesterday. 80ft of 1.5” red Sch40 and a new batch of fittings arrived yesterday, so it’s time to start glueing again:

It took me weeks to paint it due to the size, but wasn’t happy with the outcome. It’s really hard to get an even coat of paint on these long pipes. I ripped it all out yesterday. 80ft of 1.5” red Sch40 and a new batch of fittings arrived yesterday, so it’s time to start glueing again:

Been there with painting pvc, never again

Nice job with the painting!!I’m still in the plumbing phase of my build. I originally purchased standard Sch40 pipe locally and painted it charcoal gray to match Sch80 pipe but without sacrificing flow. I got all my drain runs glued and painted:

It took me weeks to paint it due to the size, but wasn’t happy with the outcome. It’s really hard to get an even coat of paint on these long pipes. I ripped it all out yesterday. 80ft of 1.5” red Sch40 and a new batch of fittings arrived yesterday, so it’s time to start glueing again:

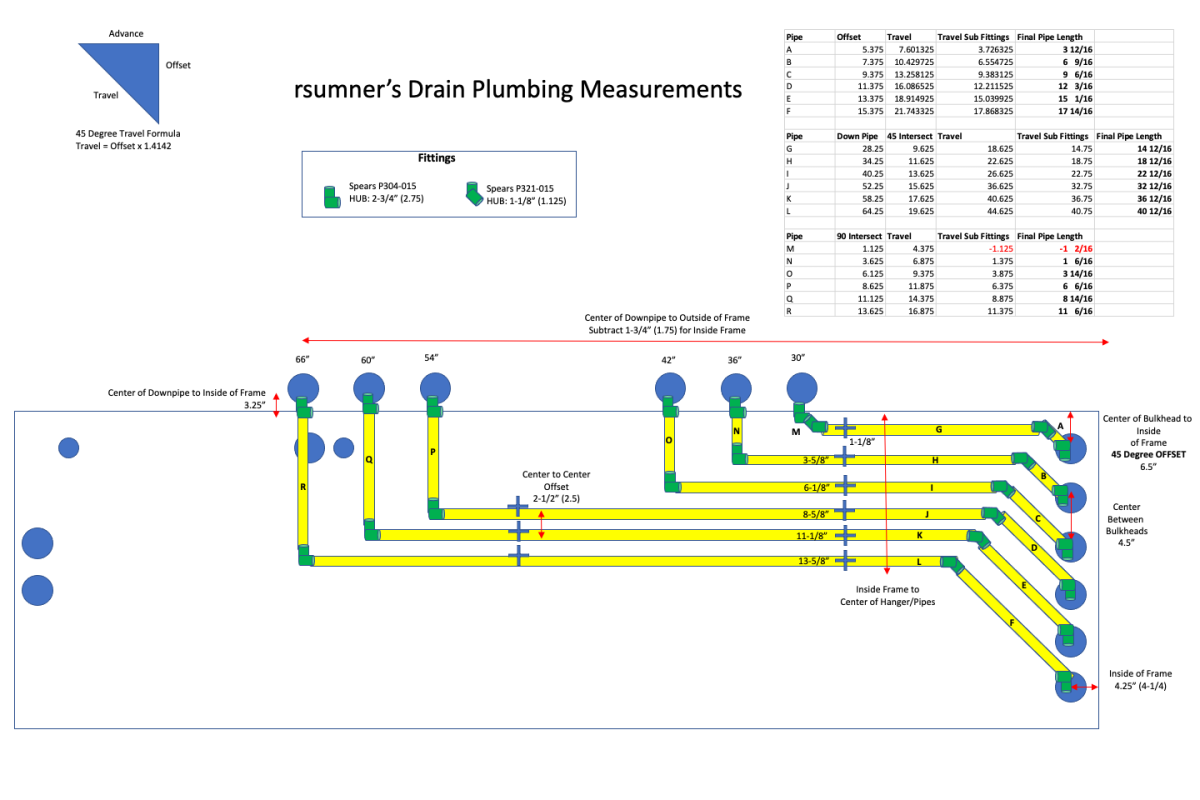

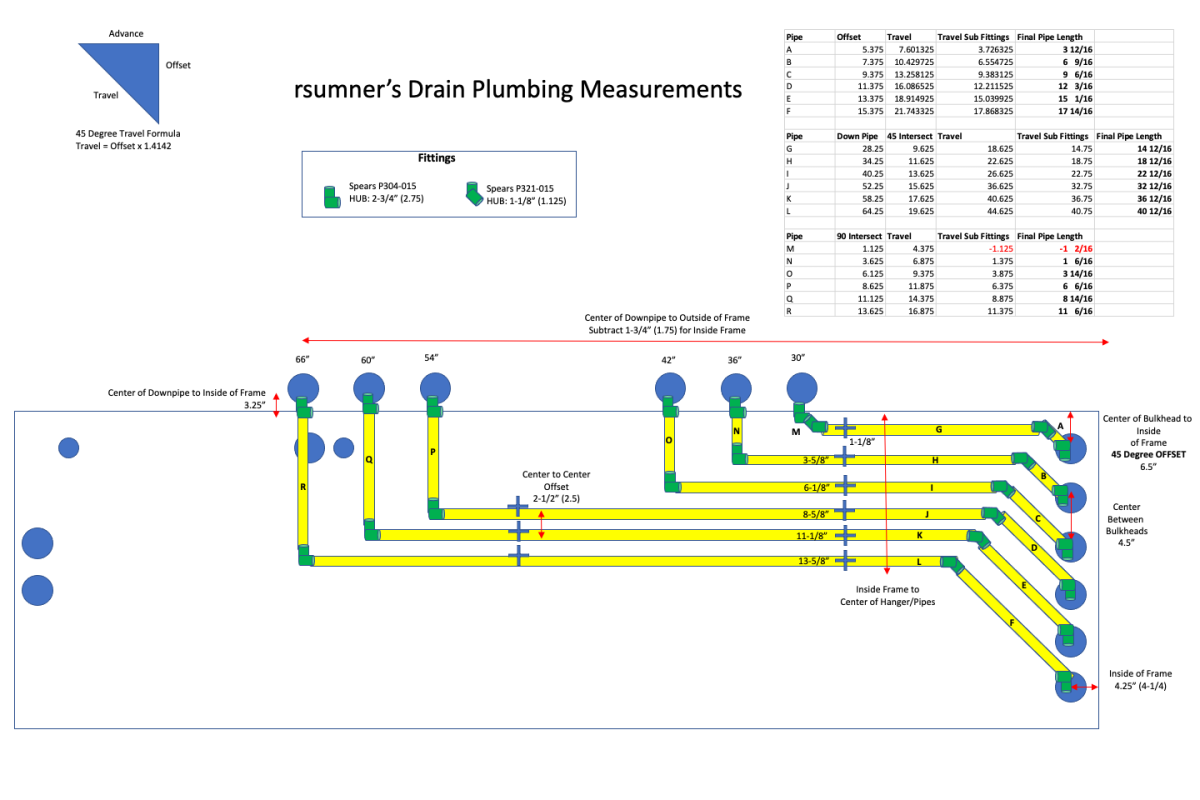

Attached is a drawing and embedded spreadsheet that I used to calculate all the pipe lengths (accurate to 1/16").

My advice to anyone doing complicated plumbing like this is to do the math and don't eyeball it. Find a common reference point between your overflow drains and the sump bulkheads and take measurements. If your sump and display drains are consistently spaced as they should be, you should be able to take a few simple measurements and then use offsets for everything else. This will make all of your plumbing lines consistently spaced and nice and pretty.

Everything in plumbing is done off the "center-to-center" of the pipes. If you combine that with the center-to-center on the fittings (also called the HUB) you are using, then its basic subtraction or addition. I suggest using the same manufacturer for all your fittings that way you only have to reference one specification document to get the specs for the fittings. I don't do plumbing for a living, but I think there are standards for these measurements if you are using DWV fittings.

By using the spreadsheet and Excel formulas, I'm able to get exact measurements for all 18 pipes I need to cut. As you can see in the spreadsheet, I only have one pipe that is RED and that's the pipe labeled as "M". In that case, I'll use a 90 and a 45 instead of two 90s and will need to make adjustments to pipe "G" to accommodate due to the differences in the HUB measurements on the 45 vs 90.

I'll do some test cuts with all the left over pipe I have to test my math before I go crazy cutting all of my pretty red pipe. One of these days, I'll spend the time to write an end-to-end plumbing article.

My advice to anyone doing complicated plumbing like this is to do the math and don't eyeball it. Find a common reference point between your overflow drains and the sump bulkheads and take measurements. If your sump and display drains are consistently spaced as they should be, you should be able to take a few simple measurements and then use offsets for everything else. This will make all of your plumbing lines consistently spaced and nice and pretty.

Everything in plumbing is done off the "center-to-center" of the pipes. If you combine that with the center-to-center on the fittings (also called the HUB) you are using, then its basic subtraction or addition. I suggest using the same manufacturer for all your fittings that way you only have to reference one specification document to get the specs for the fittings. I don't do plumbing for a living, but I think there are standards for these measurements if you are using DWV fittings.

By using the spreadsheet and Excel formulas, I'm able to get exact measurements for all 18 pipes I need to cut. As you can see in the spreadsheet, I only have one pipe that is RED and that's the pipe labeled as "M". In that case, I'll use a 90 and a 45 instead of two 90s and will need to make adjustments to pipe "G" to accommodate due to the differences in the HUB measurements on the 45 vs 90.

I'll do some test cuts with all the left over pipe I have to test my math before I go crazy cutting all of my pretty red pipe. One of these days, I'll spend the time to write an end-to-end plumbing article.

Last edited:

What paint do you use for the plumbing?

What paint do you use for the plumbing?

The new pipe won’t be painted at all, but here’s the supplies I used for the first version.

First, give the pipe and fittings a light sanding with 220 grit sandpaper. Then, wipe it down really good with acetone. I then put 4 light/thin coats of the charcoal gray waiting 30 minutes between coats. Then, I waited 24 hours before doing 4 light coats of the clear gloss. After that, let it cure for 48 hours before handling it.

Thanks, so obviously no risk of peeling overtime with that brand

Thanks, so obviously no risk of peeling overtime with that brand

Just make sure you do the prep sanding wiping with acetone. Then, as long as you apply in light coats and let it cure, then it shouldn't peel.

Good to know, thanks

New red drain lines are cut and glued. I still need to cut the final pieces to connect these to the dual overflows, but this took a day and a half, so I need a break.

Having the pipe lengths already calculated allowed me to cut them in one trip to the saw and giving me labeled inventory to reference my drawing and spreadsheet when it was time for assembly.

And the final product :

Having the pipe lengths already calculated allowed me to cut them in one trip to the saw and giving me labeled inventory to reference my drawing and spreadsheet when it was time for assembly.

And the final product :

Last edited:

Attached is a drawing and embedded spreadsheet that I used to calculate all the pipe lengths (accurate to 1/16").

My advice to anyone doing complicated plumbing like this is to do the math and don't eyeball it. Find a common reference point between your overflow drains and the sump bulkheads and take measurements. If your sump and display drains are consistently spaced as they should be, you should be able to take a few simple measurements and then use offsets for everything else. This will make all of your plumbing lines consistently spaced and nice and pretty.

Everything in plumbing is done off the "center-to-center" of the pipes. If you combine that with the center-to-center on the fittings (also called the HUB) you are using, then its basic subtraction or addition. I suggest using the same manufacturer for all your fittings that way you only have to reference one specification document to get the specs for the fittings. I don't do plumbing for a living, but I think there are standards for these measurements if you are using DWV fittings.

By using the spreadsheet and Excel formulas, I'm able to get exact measurements for all 18 pipes I need to cut. As you can see in the spreadsheet, I only have one pipe that is RED and that's the pipe labeled as "M". In that case, I'll use a 90 and a 45 instead of two 90s and will need to make adjustments to pipe "G" to accommodate due to the differences in the HUB measurements on the 45 vs 90.

I'll do some test cuts with all the left over pipe I have to test my math before I go crazy cutting all of my pretty red pipe. One of these days, I'll spend the time to write an end-to-end plumbing article.

New red drain lines are cut and glued. I still need to cut the final pieces to connect these to the dual overflows, but this took a day and a half, so I need a break.

Having the pipe lengths already calculated allowed me to cut them in one trip to the saw and giving me labeled inventory to reference my drawing and spreadsheet when it was time for assembly.

And the final product :

This is really great work! I could see you making a business opportunity out of this doing made to measure pipes and plans for other people's tank plumbing.

Thanks! That high school geometry was finally useful.This is really great work! I could see you making a business opportunity out of this doing made to measure pipes and plans for other people's tank plumbing.

great build and will follow along - very nice work on the plumbing

Amazing work

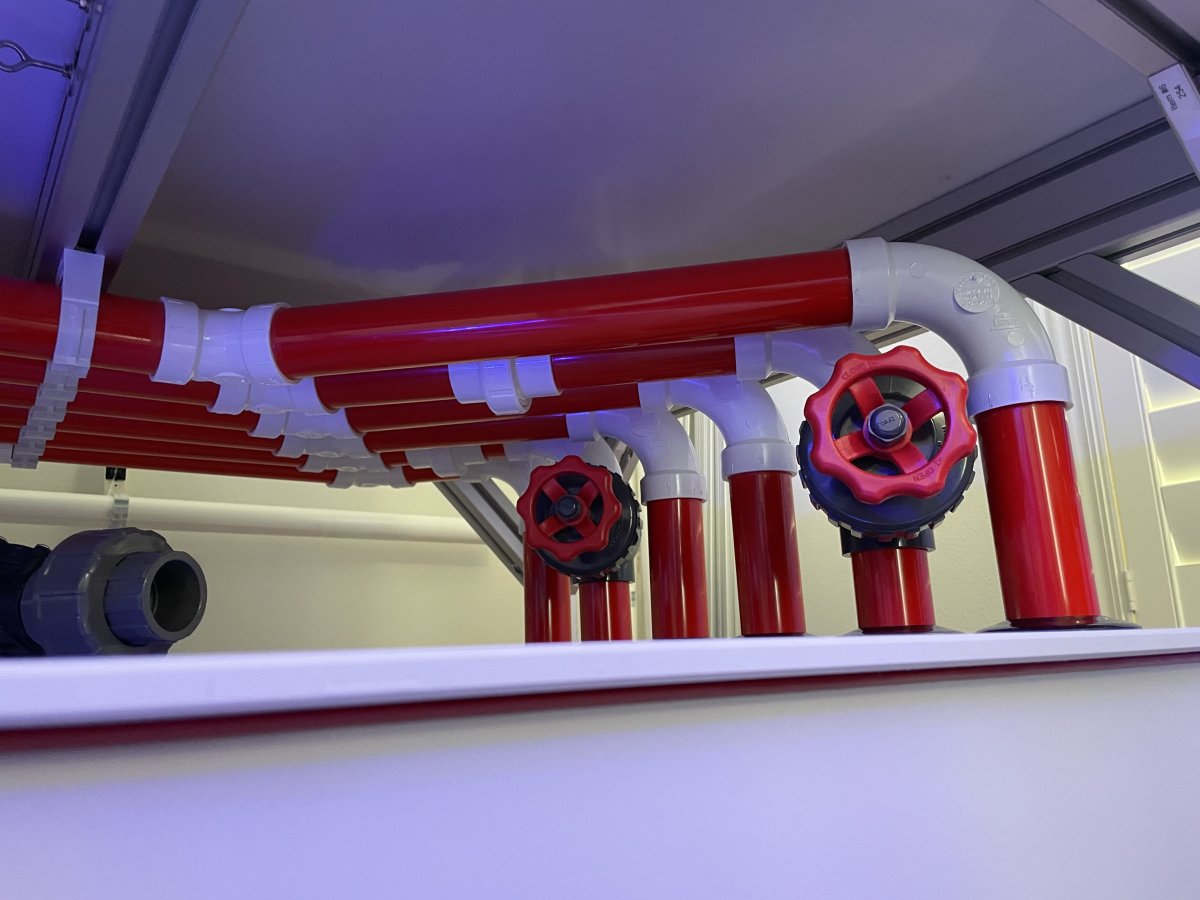

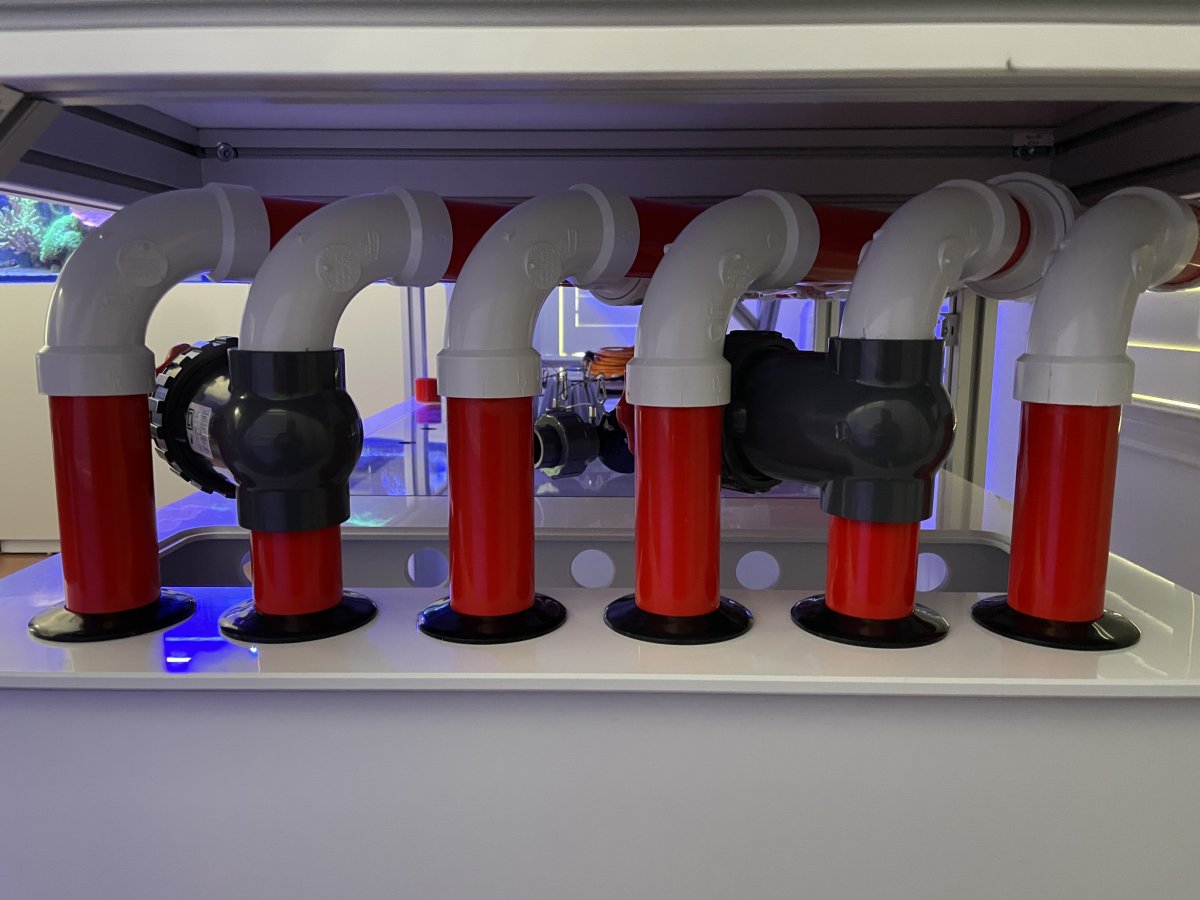

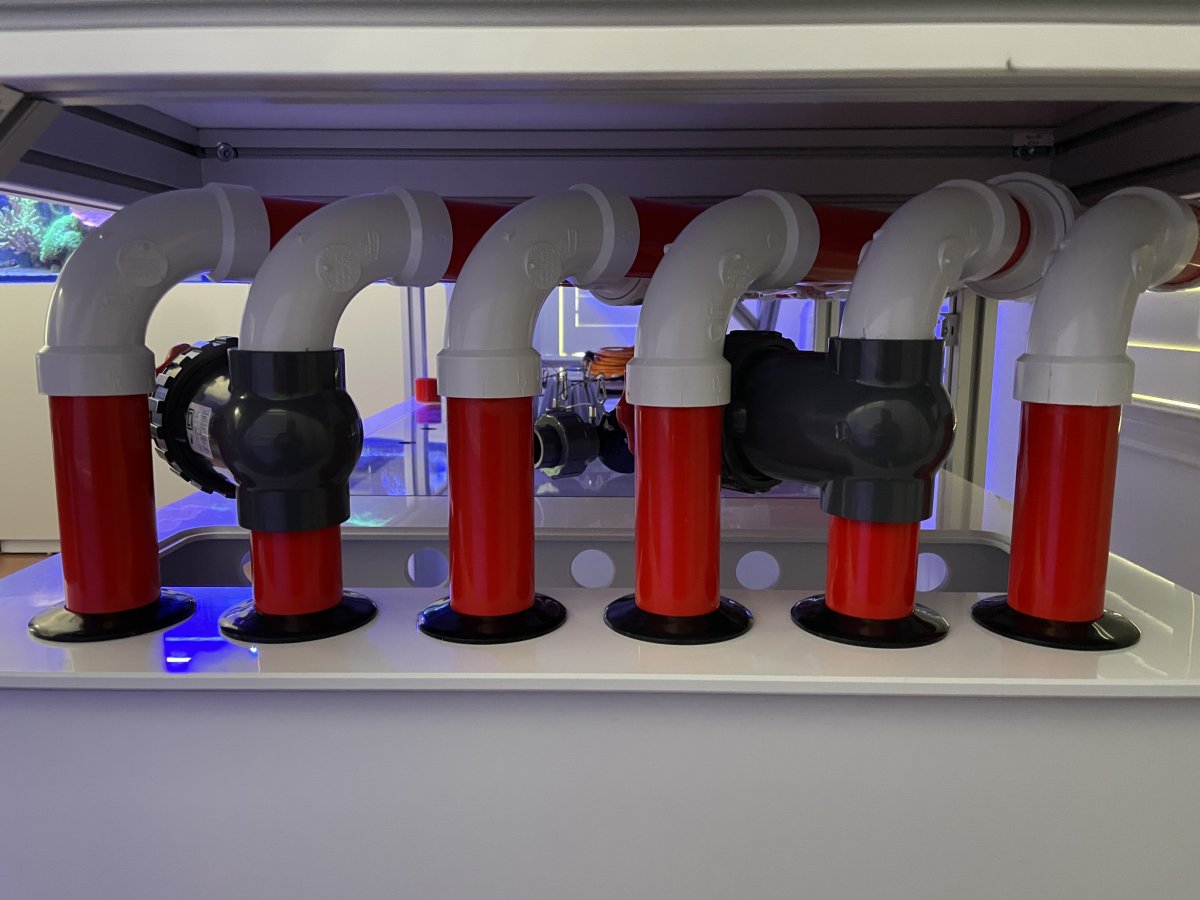

Making some major progress on the plumbing over the past few days. Drains are connected to the overflows and return lines are glued to the return bulkheads.

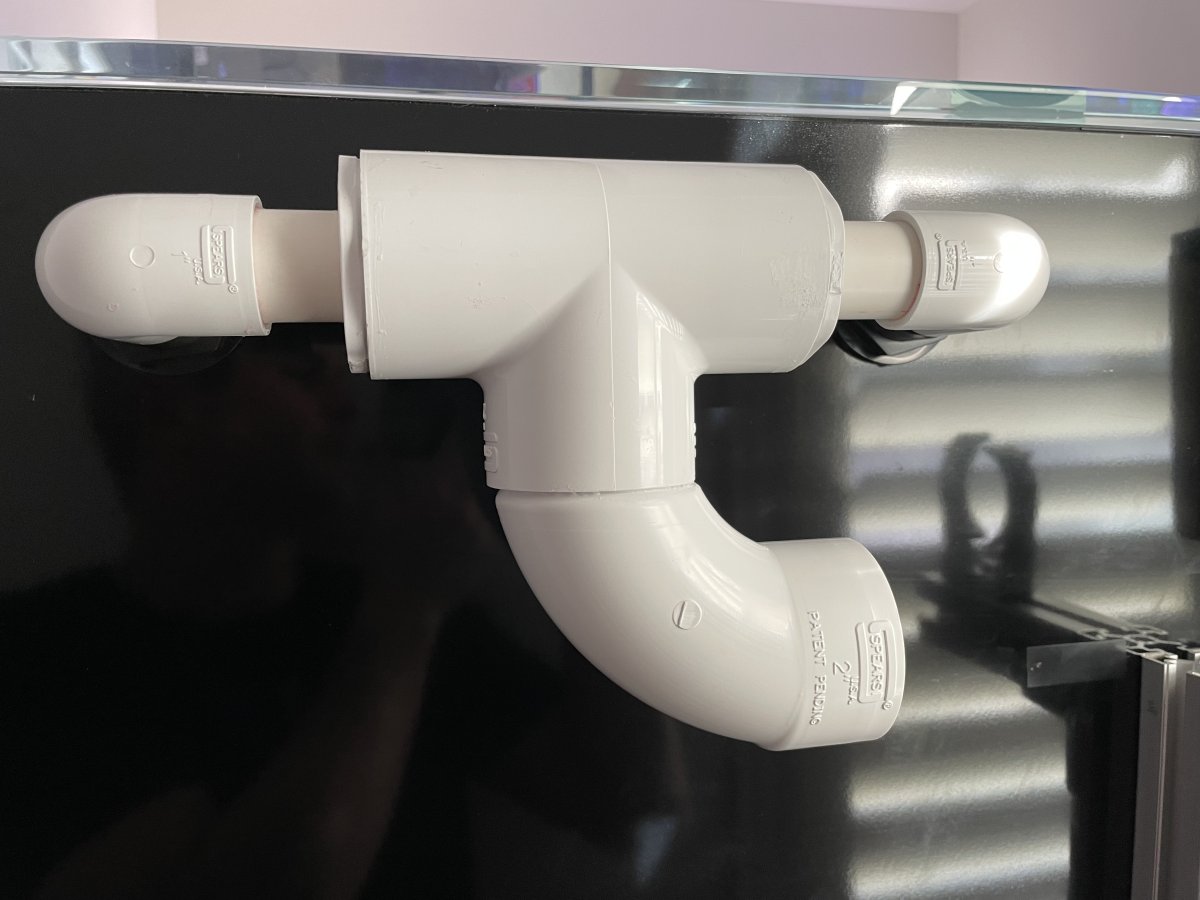

I have a total of 5 1” return bulkheads. I supply water to the two on the right and two on the left with a 2” pipe tee’ed to two 1” elbows that connect to the bulkheads on the back wall of the tank. The 5th middle return has its own 1” line that will be dedicated to a chiller. Each of the 2” returns run off independent Abyzz A200’s and the chiller will have its own pump too.

As I did with my drain lines, I use sweeping 90s where possible to reduce head pressure.

I’m waiting on some more pipe clamps to arrive tomorrow so I can glue the skimmer supply, skimmer drain, and pump supplies to the sump. After that, I’ll be able to push the tank back against the wall and finish the UV plumbing . Then, I’ll be able to do a leak test of the plumbing end-to-end.

I have a total of 5 1” return bulkheads. I supply water to the two on the right and two on the left with a 2” pipe tee’ed to two 1” elbows that connect to the bulkheads on the back wall of the tank. The 5th middle return has its own 1” line that will be dedicated to a chiller. Each of the 2” returns run off independent Abyzz A200’s and the chiller will have its own pump too.

As I did with my drain lines, I use sweeping 90s where possible to reduce head pressure.

I’m waiting on some more pipe clamps to arrive tomorrow so I can glue the skimmer supply, skimmer drain, and pump supplies to the sump. After that, I’ll be able to push the tank back against the wall and finish the UV plumbing . Then, I’ll be able to do a leak test of the plumbing end-to-end.

Last edited:

Similar threads

- Replies

- 5

- Views

- 250

- Replies

- 2

- Views

- 150

- Replies

- 7

- Views

- 322

- Replies

- 19

- Views

- 1,624

TOP 10 Trending Threads

- Replies

- 53

- Views

- 629

-

- Poll

- Replies

- 23

- Views

- 297

- Replies

- 27

- Views

- 437

-

- Poll

- Replies

- 32

- Views

- 466

- Replies

- 54

- Views

- 1,143

- Replies

- 65

- Views

- 569

- Question

- Replies

- 65

- Views

- 701

- Replies

- 36

- Views

- 427

- Replies

- 31

- Views

- 448