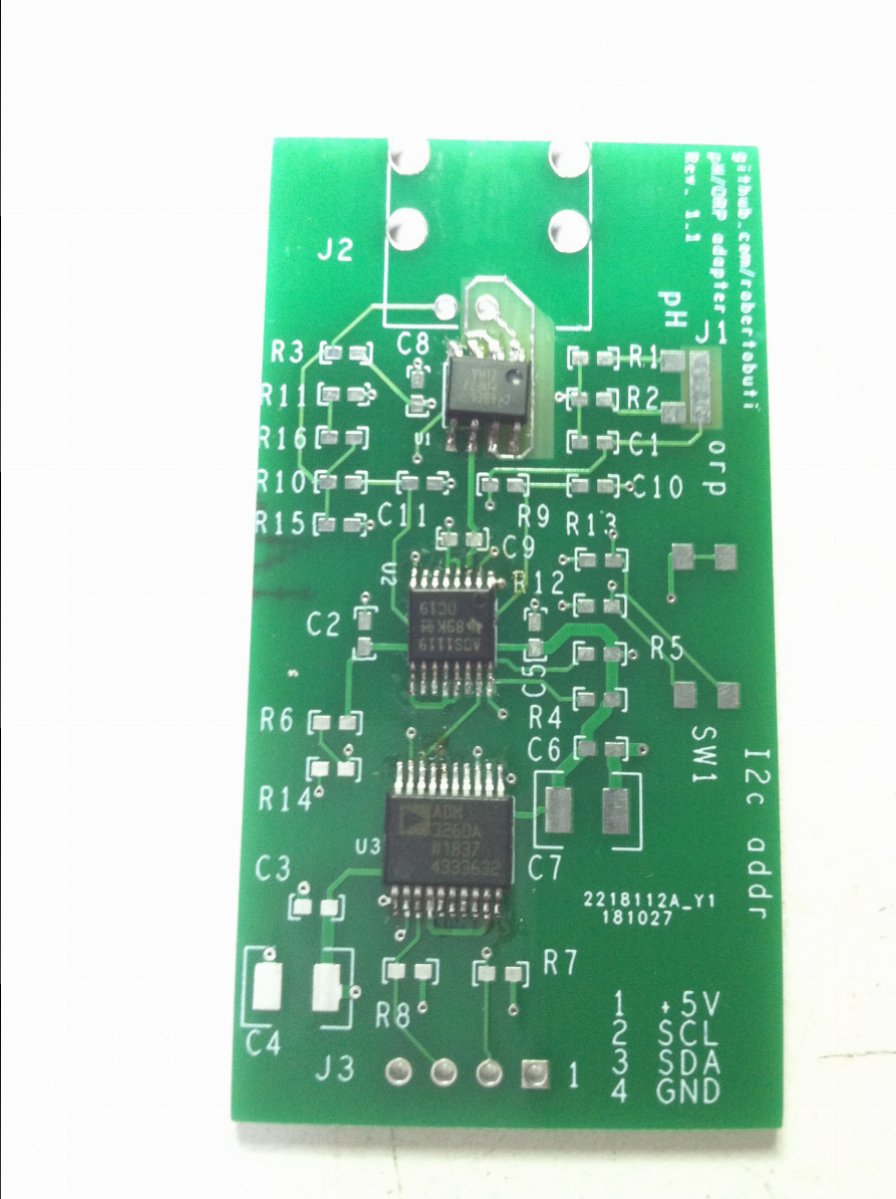

Well I was able to get the chips set on the board and they trace and pinout good. One chip slipped on me luckily it was the one with room for the mistake. I'll prob set the rest of the components later in the weekend, just wanted to knock off the harder ones first.

Thanks to everyone that continues to pour into this project.

Thanks to everyone that continues to pour into this project.