Reefers, bookmark this post. It will come in very handy for the next rodeo.Got my overflow togeather. Used weldon 16 and laid some thick beads down the inside corners, went back over all the seams on the exterior with a much thinner bead of it just to hopefully make sure it's sealed up tight.

Next part of my plan is once I drill for my bulkheads and install them I will use the weldon 16 again to attach this to the base of my grow out tank (its an ABS tub so I shouldn't have any issues)

A slightly different approach on assembly for this. I taped it all up snug then attached a square to one of the corners. That squared the whole thing up nicely. I tacked the top and bottom edges to help keep the panels from moving any at first, then I was then able to set it on edge and run the weldon 16 down the inside seam. Made it very easy for me, after 45min I would spin the box to the next corner and do the next seam. Once the inside was done I went around the outside seams and ran the weldon over them to try and get them fused from both inside and outside seams. Luckily with this being all black making a little mess with the weldon or having some not so perfect seams is not a big deal and goes unnoticed.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Tenecor® Pico DIY Drops March 2nd, 2024

- Thread starter Tenecor Aquariums

- Start date

- Tagged users None

A separate build thread or at least a list of links to posts in this thread for points on how to build would be very much appreciated !Reefers, bookmark this post. It will come in very handy for the next rodeo.

So no weldon before putting the pieces together? Just after they are taped and in place (almost like running a bead of silicone)? Does the thicker Weldon 16 wick all the way across the interface for a full bond?Got my overflow togeather. Used weldon 16 and laid some thick beads down the inside corners, went back over all the seams on the exterior with a much thinner bead of it just to hopefully make sure it's sealed up tight.

Next part of my plan is once I drill for my bulkheads and install them I will use the weldon 16 again to attach this to the base of my grow out tank (its an ABS tub so I shouldn't have any issues)

A slightly different approach on assembly for this. I taped it all up snug then attached a square to one of the corners. That squared the whole thing up nicely. I tacked the top and bottom edges to help keep the panels from moving any at first, then I was then able to set it on edge and run the weldon 16 down the inside seam. Made it very easy for me, after 45min I would spin the box to the next corner and do the next seam. Once the inside was done I went around the outside seams and ran the weldon over them to try and get them fused from both inside and outside seams. Luckily with this being all black making a little mess with the weldon or having some not so perfect seams is not a big deal and goes unnoticed.

Take a look at all the new nanos we now have. Thanks to all of you for the input >>> https://www.tenecoraquariums.com/collections/aio-frag-tanks

All are available. Shrimp tanks, bookshelves and (Next diy?) >>> drop offs <<< (Next diy?) coming.

All are available. Shrimp tanks, bookshelves and (Next diy?) >>> drop offs <<< (Next diy?) coming.

Yes, outside of tacking the top and bottom edges I ran it as if it was a fine bead of silicone. Thicker on the inside seams and much more into the seams from the outside with a syringe tip squeeze bottle. On the inside seams the weldon went on thick, I had the overflow on edge so i had gravity of doing the work for pulling the weldon into the joint.So no weldon before putting the pieces together? Just after they are taped and in place (almost like running a bead of silicone)? Does the thicker Weldon 16 wick all the way across the interface for a full bond?

I will add that I don't plan to do my tank kit this way. I'm going to be aiming to get the best fusion I can on that so I'll be trying to inject between the panels rather then letting the solvent pull into them like I have on the overflow box.

Placeholder. They are coming.I'm in for a bookshelf. I was totally just looking for one a minute ago, and didn't see anything.

Here we go..

www.reef2reef.com

www.reef2reef.com

The Tenecor® Desktop AIO Drop Off DIY Drops April 13th, 2024

Greetings Reefers! Time for another drop. This DIY will be more difficult than the Pico with more challenging geometries. The preliminary dimensions will be 15x11x15 (LxWxH) measured in the King's English. This DIY like the last pico, will be full featured, no shortcuts or omissions. we will...

www.reef2reef.com

www.reef2reef.com

24x10x10 with 4" aio end, No tab baffle is my vote. Lid only on display. Euro brace .5 to .75 max14x10x10, 16x10x10, 18x10x10., 24x10x10. All of them as peninsula AIO DIY.

Edit: Brace only on 20" of display to free up AIO end for more DIY baffle combos or even a HOB.

Edit: Non tabbed baffles at minimum for AIO customizing with .5 or 1" etched line top to bottom for guide/pre-score to cut off/snap off to make narrower baffle if 4" AIO end is to big.

Watched many Pico bookshelf videos. Narrow 8 to 9 wide leaves very little room between sides and rock. (Vic WWC) Edit: Absolute min width of 9" if masses don't like 10" you proposed.

Last edited:

Full front to back AIO end equals more room. Paint or vinyl wrap end to hide what's inside.

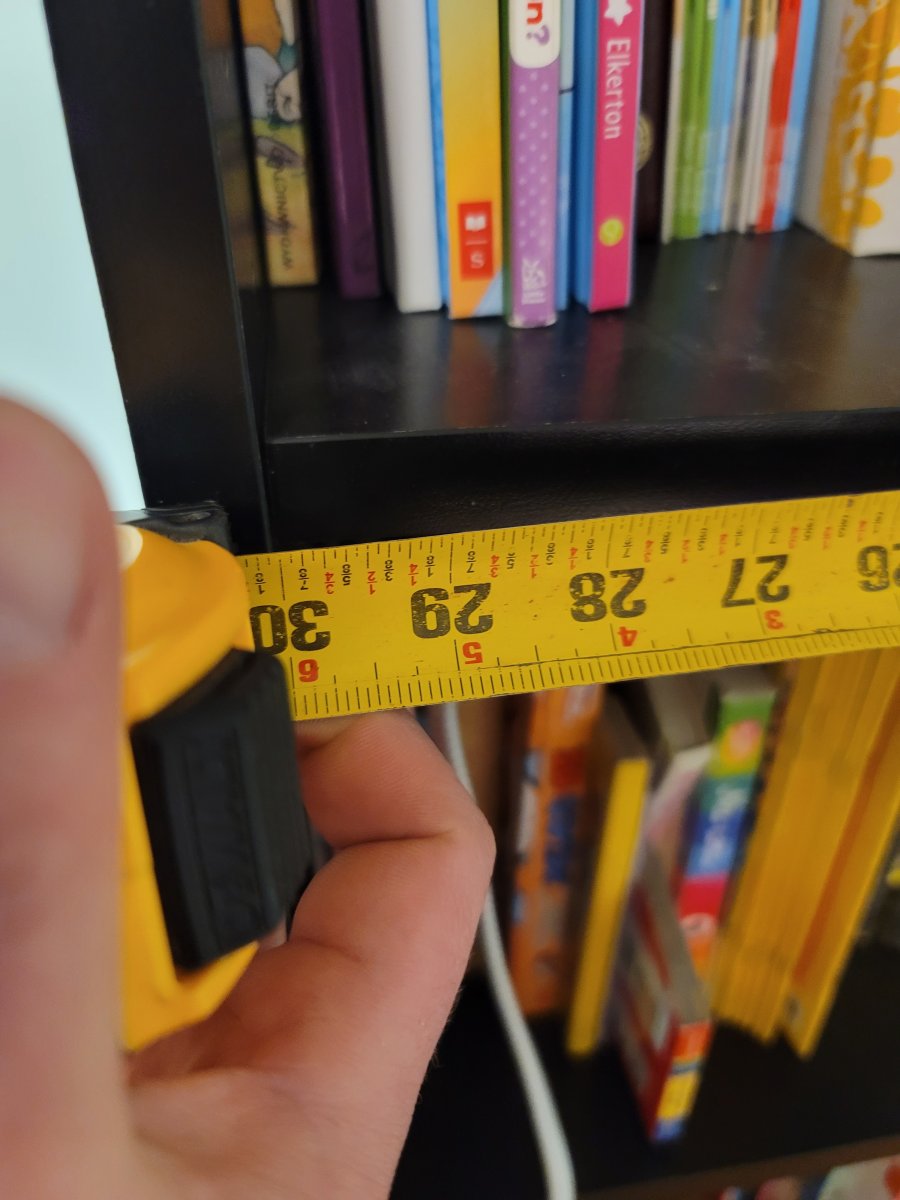

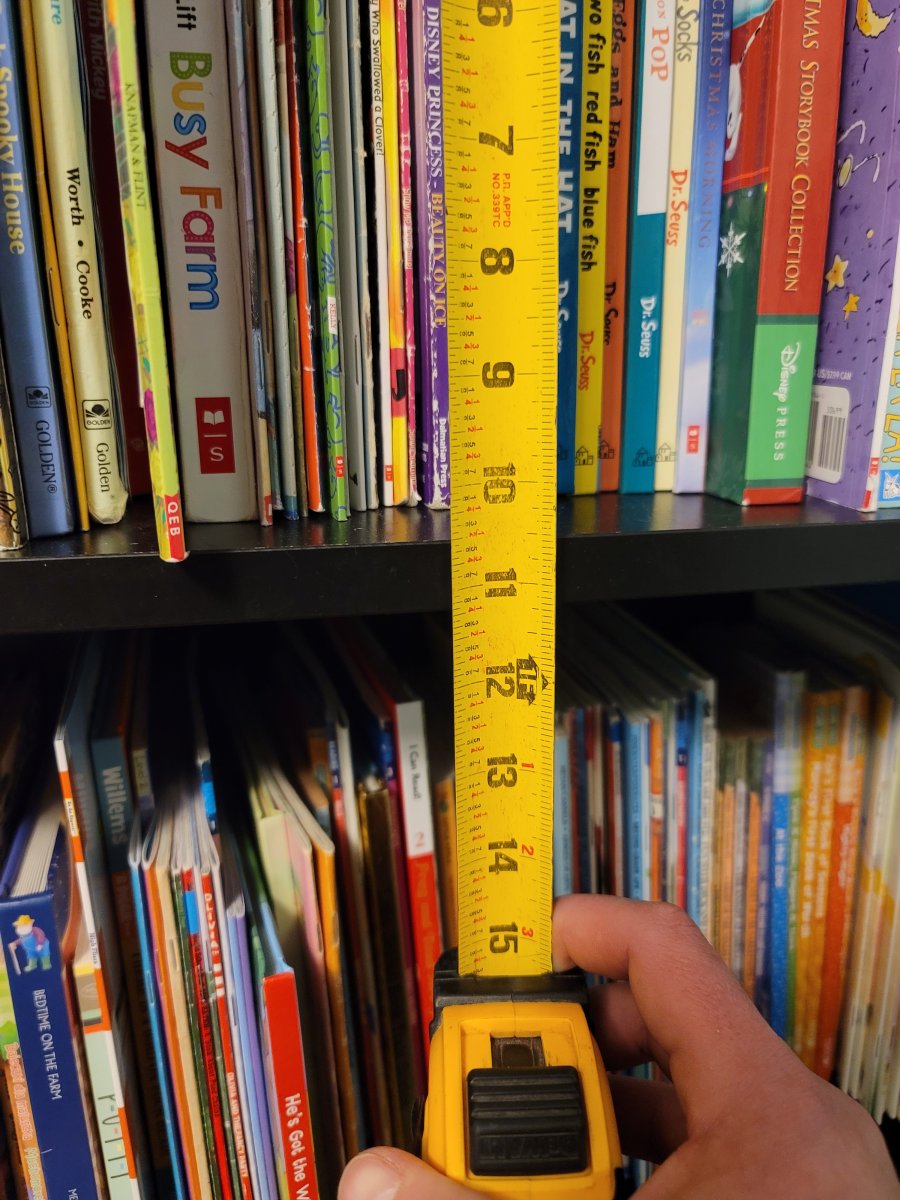

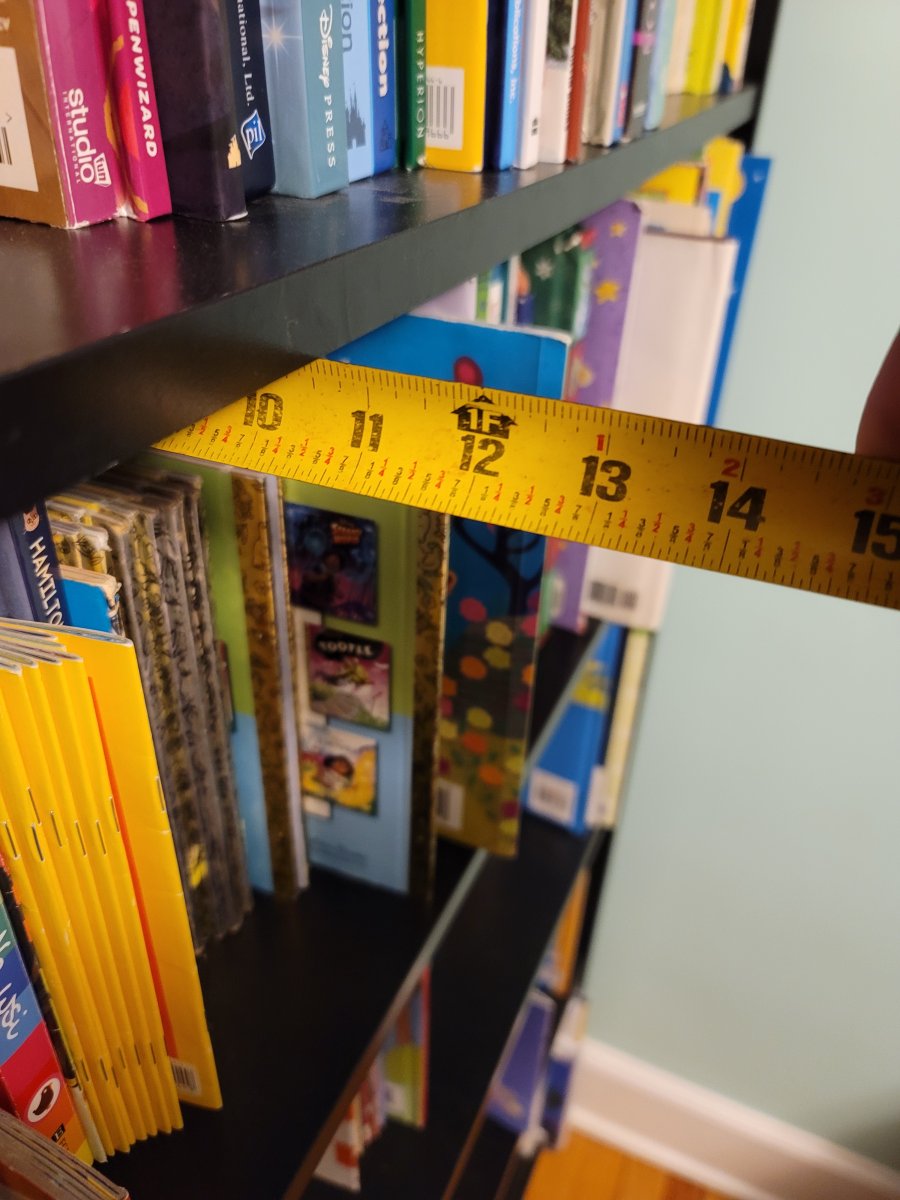

Will you be adding extra shelf support or relying on the little pins to hold 50 to 70lbs?I grabbed some measurements of the book shelves.

One was 29 x 8.75w x 12t and the other was 30 x 10.5w x 10.5 t.

I think for it to fit on a bookshelf something like a 16x8x8 for the viewing area plus the number of inches in length for the AIO (which I'm not sure if that is 2 or 4 inches), so maybe 20x8x8 overall? That gives you a nice 5.5 gallon setup, so about 50 lbs when going onto a bookshelf.

As for lighting, someone else may need to chime in, whether something exists that can fit in that remaining head space?

Believe it or not I believe these are rated 100+ lbs, but I would probably add boards under it.Will you be adding extra shelf support or relying on the little pins to hold 50 to 70lbs?

I read yesterday’s post about the top but couldn’t follow. What do we do with those rectangular pieces to construct the top?

Got late start day 2. Enjoyed day 1, although it was a bit messy. Is it possible to have perforated edges so that only an outer layer of protective paper can be removed at first and then remainder after acrylic applied?

I used blue tape on both sides of the layer of acrylic to be applied, which helped limit where acrylic smudged (and leave a straight line).

But inevitably there were small splatters here and there on other pieces — I was mostly able to get rid of those with a wet towel nearby if I caught some asap. There were spots I missed bc Weld-On 16 just dripped out of applicator even when no pressure applied so I didn’t notice.

I suppose there’s no nontoxic chemicals that can remove the acrylic smudges or beads? Though I’m inclined to leave it on as a reminder, “I built that!”

Got late start day 2. Enjoyed day 1, although it was a bit messy. Is it possible to have perforated edges so that only an outer layer of protective paper can be removed at first and then remainder after acrylic applied?

I used blue tape on both sides of the layer of acrylic to be applied, which helped limit where acrylic smudged (and leave a straight line).

But inevitably there were small splatters here and there on other pieces — I was mostly able to get rid of those with a wet towel nearby if I caught some asap. There were spots I missed bc Weld-On 16 just dripped out of applicator even when no pressure applied so I didn’t notice.

I suppose there’s no nontoxic chemicals that can remove the acrylic smudges or beads? Though I’m inclined to leave it on as a reminder, “I built that!”

Just received the pico last night and starting to dry fit. A couple questions for those that have worked with acrylic before and/or already put this one together…

1) Is it possible to apply Weldon 4 in between the clamps, let it set / dry, and then remove the clamps and Weldon 4 the corners, where the clamps are holding the sheets?

2) at what step did you weld the AIO to the tank? If I put the top on before the bottom, it will probably make it a bit difficult to get the AIO setup but I think this might be one of the only ways

1) Is it possible to apply Weldon 4 in between the clamps, let it set / dry, and then remove the clamps and Weldon 4 the corners, where the clamps are holding the sheets?

2) at what step did you weld the AIO to the tank? If I put the top on before the bottom, it will probably make it a bit difficult to get the AIO setup but I think this might be one of the only ways

Agree for tank to be useable absolute minimum is like 9” deep. At least 0.5” needed from panels on each side so that there’s some room to scrape off algae/do maintenance. So approx 8” useable space? Even small coral frags have very sizable volume when polyps are extended. Small Marco rocks or live rock pieces also are what — often 3.5” to 4.0” wide (at least based on what I have)??? And if we add fish to the equation we have to give them some room to maneuver.24x10x10 with 4" aio end, No tab baffle is my vote. Lid only on display. Euro brace .5 to .75 max

Edit: Brace only on 20" of display to free up AIO end for more DIY baffle combos or even a HOB.

Edit: Non tabbed baffles at minimum for AIO customizing with .5 or 1" etched line top to bottom for guide/pre-score to cut off/snap off to make narrower baffle if 4" AIO end is to big.

Watched many Pico bookshelf videos. Narrow 8 to 9 wide leaves very little room between sides and rock. (Vic WWC) Edit: Absolute min width of 9" if masses don't like 10" you proposed.

10" wide anyone????Agree for tank to be useable absolute minimum is like 9” deep. At least 0.5” needed from panels on each side so that there’s some room to scrape off algae/do maintenance. So approx 8” useable space? Even small coral frags have very sizable volume when polyps are extended. Small Marco rocks or live rock pieces also are what — often 3.5” to 4.0” wide (at least based on what I have)??? And if we add fish to the equation we have to give them some room to maneuver.

Ok, if you did not yet try to weld this up, stop. Remove the protective paper from a good portion close to the seams or better yet, all of it. If those are the walls and that is the bottom, it won't work well. You need to assemble all the walls to each other first. This creates a perimeter. Then that perimeter assembly will be attached to the TOP. And those clamps will get in the way. The Weldon will probably melt them too. So, if youu are attaching all the walls to each other, what you can do is leave everything the way you have it and tack a couple or more spots on the OUTSIDE with silicone. Do this to the other Let it cure then you can remove the clamps, square up the tacked pieces from the outside, tape all four pieces TIGHTLY but square and then run the Weldon on the inside. Do only one seam at a time and let it set up. This is the other most common error, rushing it.Just received the pico last night and starting to dry fit. A couple questions for those that have worked with acrylic before and/or already put this one together…

1) Is it possible to apply Weldon 4 in between the clamps, let it set / dry, and then remove the clamps and Weldon 4 the corners, where the clamps are holding the sheets?

2) at what step did you weld the AIO to the tank? If I put the top on before the bottom, it will probably make it a bit difficult to get the AIO setup but I think this might be one of the only ways

EDIT: The AIO assembly attaches to the tank last. Might I recommend straight silicone on that? You are going to run into all sorts of trouble when trying to attach the filter wall to the bottom as well as the side walls. This is why we don't build true coast to coast AIO's

Ok, if you did not yet try to weld this up, stop. Remove the protective paper from a good portion close to the seams or better yet, all of it. If those are the walls and that is the bottom, it won't work well. You need to assemble all the walls to each other first. This creates a perimeter. Then that perimeter assembly will be attached to the TOP. And those clamps will get in the way. The Weldon will probably melt them too. So, if youu are attaching all the walls to each other, what you can do is leave everything the way you have it and tack a couple or more spots on the OUTSIDE with silicone. Do this to the other Let it cure then you can remove the clamps, square up the tacked pieces from the outside, tape all four pieces TIGHTLY but square and then run the Weldon on the inside. Do only one seam at a time and let it set up. This is the other most common error, rushing it.

EDIT: The AIO assembly attaches to the tank last. Might I recommend straight silicone on that? You are going to run into all sorts of trouble when trying to attach the filter wall to the bottom as well as the side walls. This is why we don't build true coast to coast AIO's

That was just me playing w the clamps and dry fitting the sides to the front. Understand the prep work before starting to weld & to weld all the walls -> top -> bottom. Was just trying to first figure out the best way to keep them square. Thanks for the feedback!

Should we do the AIO wall and baffle after the walls are done and before the bottom? Or after bottom is done?

Dry fit everything and attempted my first weld. Thought I got it drawn into the seam pretty well but it sure enough didn’t. Used the 4. I have used it in the past and went great. Wonder if I had the two walls pulled together to tight with tape to allow it to flow in. No worries though. The one corner will be done over with 16 and used as the back corner where then AIO chamber will be.

I’d buy one with those dimensions at 10” and/or 12” deep. There are so many books around the home that can accommodate something of that depth.10" wide anyone????

Similar threads

- Replies

- 372

- Views

- 9,645

- Replies

- 53

- Views

- 995

- Replies

- 69

- Views

- 2,961

-

- AMS: Article

- Replies

- 62

- Views

- 5,885

- Replies

- 1

- Views

- 576