Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Water Lily Reef (180g In-wall)

- Large Build

- Thread starter DLHDesign

- Start date

- Tagged users None

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

Great dosing setup.

06/07/2018 - Day 0

Still "Day 0" because the house is still being built. It's coming along, however - there is a floor (concrete pad), walls (just timbers; no wires, plumbing, drywall, paint, ...), and a roof (of bare wood)! So while we can walk through it, we can literally walk through the walls of it... Still; progress. ETA is "late August". We'll see how that goes, of course.

Meanwhile, I make some small incremental progress on the tank. Or the stuff that will support the tank, at least...

The rock has all cycled. I give it some ammonia once a week or so just to keep things moving along (can't have too much bacteria to start, eh?), but I'm not really monitoring anything. I spent a few days feeding it ammonia, watching it drop, then watching nitrites/nitrates drop. Repeated it again a few days later. Then again. Each time, the duration involved reduced. So I'm calling the rock "cycled", I guess. Still no tank to put them in, much less a (ahem) house to put the tank in if I had it. So they'll just stay in the cans for now.

I've given some more thought to the scape and imagine that I'll likely either have to do some cutting of the rock to make some flat surfaces (ugh), or else buy up some of the Reef Saver Shelf that BRS now offers. The latter seems appealing - especially given that I wanted more rock anyways - even though it means going through another cure (and ideally cycle) process. Luckily, I have just freed up a Brute can for just such a purpose.

How did I free up a Brute can, you ask? Okay; you likely didn't ask that. But I'm going to pretend you did so that I can move my narrative along...

What was I talking about, again? OH! Brute can free-up. My salt mixing can is no longer needed, because I have a shiny new Mixing Station!

I went all-out on this thing. Perhaps too much so, but mixing salt, RO/DI stuff, and water changes are things I don't really enjoy - they are a chore (especially water changes, eh?). I thought about all the things that I've run into since I started the tank and tried to come up with a way to make it easier. In the end, there's nothing really novel about most (any) of it, I don't figure. It's just that it has a lot more than I imagine most people put into their Mixing Stations...

I started with two 55gal vertical, square tanks. These are large enough that I should be able to have something close to a 40-50% water change supply on-hand at any moment in just ready-mixed salt. After that's used, I could mix up another tank in a matter of minutes. I doubt I'll ever need to do that, but it's an option. Square because I always seem to be coming up with things to put into the tank and usually need a flat spot to do so (bulkhead or magnet). I have lots of places to put things, in other words.

The stand is nothing overly unusual; 2x4's in a fairly standard "tank stand" layout. The height leaves enough room under the drain spigot (right side) to get even one of my taller buckets under, yet leaves the top of the tanks low enough that I can see into them without using a step-ladder (though only just; I can't really DO anything aside from see). I painted the stand blue (the color of the build, in case I didn't mention that before) and then topped it with a thick primer followed by some spray-on PlastiDip. The PlastiDip was less effective than I hoped - even with two spray cans worth. When we move, I may get some of the brush-on kind and just pour that over it. Goal being to create a water-resistant surface (because - spills). Some storage under the stand for hoses and such as well.

The plumbing is all 1". My old setup used 1/2" and it was always painful to move water around. Even filling a 1gal jug to mix up some new 2-part was tiresome. Not so with the 1" plumbing. Water MOVES through that stuff. I'm sure it's also because of the pump - which is a Pan World 50PX-X I picked up from BRS as an "open box". With a max flow of ~1110GPH, this thing has no problems handling anything I need it to do! It's a far cry from the 1/2" pump I re-serviced from my brewing days that I had been using. That alone was worth the rebuild.

But also; automation. Oh, the automation...

None of it works yet. :-\

Okay; that's not true - some of it works. My old mixing station used a Hydor Koralia of some size. It worked; no complaints. With this build, however, I wanted something that I could have a bit more control over - not just plug it in and let it run. Since I've already got a WXM and have already confirmed that it's range is decent, I picked up an MP10WQD. Having a fully-controllable pump in the mixing container has allowed me to run it FAR less - 5 minutes out of every hour. This will keep the water moving about, but not burn power constantly. I can also run it at something low (currently 20%) instead of full-blast. Finally; I set up something like a "feed mode" that allows me to kick it up to 100% when I'm mixing. I'll also tie it into the AWC DOS so that it kicks on when the AWC is pulling salt water (or a few minutes before, ideally). This isn't really a huge deal and I doubt that the energy savings will every really pay for the pump, but I liked the idea of it, so there it is.

Also working is the RO/DI. The eventual plan is to swap out my current 6-stage system for a 7-stage setup. I've got everything I need to do that, but I still have a canister or two of 6-stage resin to use up. I reconfigured my lines a bit more to make it easier to turn the system on, however. I used to have to turn my booster pump on/off manually after opening the water up, but now it comes on automatically (using a pressure switch). I've had the switches in there for a while, they were just in the wrong place and I was too busy (read: lazy) to change them. All good now. I left in a manual diversion setup I use to manually flush the system. I've got TDS meters all over the place in that thing (9 total) and I've learned that the first few minutes of water - even after the auto-flush - comes in pretty high; in the 100+ range most times. It settles down into the 10-12 range after a few minutes, but that initial hit was resulting in far faster depletion than I get now. I may decide to use a few solenoids to handle all of that for me, but will likely hold off on that until there's a good way to measure TDS in real-time via the Apex. The goal is to balance saving water and resin; which I don't feel can be done well enough with clock-based assumptions. I may revisit that if I get bored, however (read: never - I have kids)... The other thing I changed about the RO/DI is that I'm no longer capturing my waste water. I feel horrible about this - I'm just dumping water down the drain whereas I used to fill the kids pool, water the lawn, clean out dirty tanks, etc. It was always slow and painful (see 1/2" pump woes above), but I felt like I was Doing Good, so that was okay. The problem is that in the new house, the fish room (and RO/DI station) will be in the middle of the house with no direct outside access. In the current house, I just ran out of room (more and more of which is being filled with boxes). Once in the new house, I'll look for a way to push a drain line outside so that I can capture it in a "rain barrel" or the like. But for now; down the drain it goes. **sigh**

The one major thing I broke was that I could no longer rely entirely upon gravity to power my ATO. I don't want to drill a low bulkhead into the clean water tank because I won't need it in the new house (that will use the PMUP-based ATO that's currently on the frag tank). So instead, I placed the new 10gal ATO container up on the top of the freezer and directed the existing ATO tube into it. Once I filled it up some, I drew from the other end to start a syphon. With that going, I hooked it back up to the ATO float in my current DT's sump and got back to ATO-ing. Only one problem: if the syphon breaks, the ATO stops working. In other words; if the tank runs dry, it's a pain to get going again. Not a huge one for me to do, but not something a house-sitter could do. And that's when it would go dry, of course... Not much I can do about that just yet. To make filling the tank easier, I ran some tubing up from the pump-out spigot into the ATO and left it in place. A few quick valve turns and the pump can fill the tank in a few seconds. That'll have to do for now (we go out of town this weekend).

That's where things are at right now. But there's more to come - oh so much more. The mixing tank has a temp and conductivity probe in it, hooked up to a PM2 module. I've got a DOS all set up with john guest fittings for an AWC setup and the mixing tank has a john guest bulkhead with a rigid drop-tube for a draw line. The mixing tank has a low-level sensor. The ATO also has a low-level sensor and I have one more for a top-level sensor. I added a flow sensor and solenoid to the main input of the RO/DI. There's an FMM module ready for all the sensors and such and all the modules have their aquabus cables and power cords.

Two things are missing, however:

1) A connection to the Apex system.

2) The water/drain lines for the AWC system.

Both of those require crawling under the house and running cabling/tubing. I've got the tubing and a length of CAT-6 wire, but am waiting on the USB connectors to build an "aquabus" cable long enough to span the distance needed. Once those arrive, I'll crawl under the house and hook it all up. Then - happy day! - no more manual water changes!!!

Oh man; the thought of that made me so happy. **sigh** Soon.

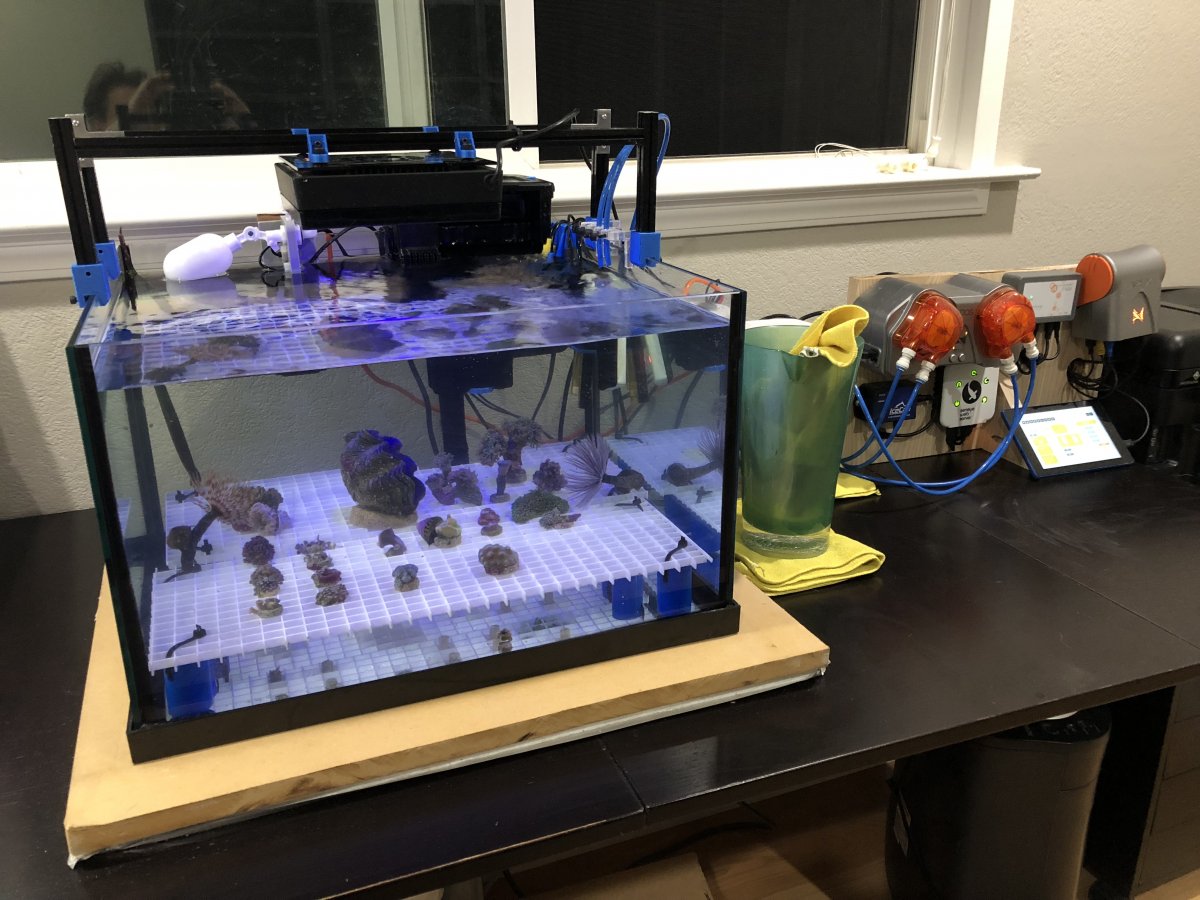

There's more to update on, but it's late and I've already written a novel tonight. I'll get some more details down, but here's a quick phone pic of the frag tank:

In short; it has it's own Apex now and I've been moving some corals over to get them into a QT. I picked up 2 clams during a live sale; one is doing well, the other not so well. I've not tested params in a few days, so I'm sure there are any number of things I could do to address the issue... That's for tomorrow (if work doesn't kill me, at least)...

Still "Day 0" because the house is still being built. It's coming along, however - there is a floor (concrete pad), walls (just timbers; no wires, plumbing, drywall, paint, ...), and a roof (of bare wood)! So while we can walk through it, we can literally walk through the walls of it... Still; progress. ETA is "late August". We'll see how that goes, of course.

Meanwhile, I make some small incremental progress on the tank. Or the stuff that will support the tank, at least...

The rock has all cycled. I give it some ammonia once a week or so just to keep things moving along (can't have too much bacteria to start, eh?), but I'm not really monitoring anything. I spent a few days feeding it ammonia, watching it drop, then watching nitrites/nitrates drop. Repeated it again a few days later. Then again. Each time, the duration involved reduced. So I'm calling the rock "cycled", I guess. Still no tank to put them in, much less a (ahem) house to put the tank in if I had it. So they'll just stay in the cans for now.

I've given some more thought to the scape and imagine that I'll likely either have to do some cutting of the rock to make some flat surfaces (ugh), or else buy up some of the Reef Saver Shelf that BRS now offers. The latter seems appealing - especially given that I wanted more rock anyways - even though it means going through another cure (and ideally cycle) process. Luckily, I have just freed up a Brute can for just such a purpose.

How did I free up a Brute can, you ask? Okay; you likely didn't ask that. But I'm going to pretend you did so that I can move my narrative along...

What was I talking about, again? OH! Brute can free-up. My salt mixing can is no longer needed, because I have a shiny new Mixing Station!

I went all-out on this thing. Perhaps too much so, but mixing salt, RO/DI stuff, and water changes are things I don't really enjoy - they are a chore (especially water changes, eh?). I thought about all the things that I've run into since I started the tank and tried to come up with a way to make it easier. In the end, there's nothing really novel about most (any) of it, I don't figure. It's just that it has a lot more than I imagine most people put into their Mixing Stations...

I started with two 55gal vertical, square tanks. These are large enough that I should be able to have something close to a 40-50% water change supply on-hand at any moment in just ready-mixed salt. After that's used, I could mix up another tank in a matter of minutes. I doubt I'll ever need to do that, but it's an option. Square because I always seem to be coming up with things to put into the tank and usually need a flat spot to do so (bulkhead or magnet). I have lots of places to put things, in other words.

The stand is nothing overly unusual; 2x4's in a fairly standard "tank stand" layout. The height leaves enough room under the drain spigot (right side) to get even one of my taller buckets under, yet leaves the top of the tanks low enough that I can see into them without using a step-ladder (though only just; I can't really DO anything aside from see). I painted the stand blue (the color of the build, in case I didn't mention that before) and then topped it with a thick primer followed by some spray-on PlastiDip. The PlastiDip was less effective than I hoped - even with two spray cans worth. When we move, I may get some of the brush-on kind and just pour that over it. Goal being to create a water-resistant surface (because - spills). Some storage under the stand for hoses and such as well.

The plumbing is all 1". My old setup used 1/2" and it was always painful to move water around. Even filling a 1gal jug to mix up some new 2-part was tiresome. Not so with the 1" plumbing. Water MOVES through that stuff. I'm sure it's also because of the pump - which is a Pan World 50PX-X I picked up from BRS as an "open box". With a max flow of ~1110GPH, this thing has no problems handling anything I need it to do! It's a far cry from the 1/2" pump I re-serviced from my brewing days that I had been using. That alone was worth the rebuild.

But also; automation. Oh, the automation...

None of it works yet. :-\

Okay; that's not true - some of it works. My old mixing station used a Hydor Koralia of some size. It worked; no complaints. With this build, however, I wanted something that I could have a bit more control over - not just plug it in and let it run. Since I've already got a WXM and have already confirmed that it's range is decent, I picked up an MP10WQD. Having a fully-controllable pump in the mixing container has allowed me to run it FAR less - 5 minutes out of every hour. This will keep the water moving about, but not burn power constantly. I can also run it at something low (currently 20%) instead of full-blast. Finally; I set up something like a "feed mode" that allows me to kick it up to 100% when I'm mixing. I'll also tie it into the AWC DOS so that it kicks on when the AWC is pulling salt water (or a few minutes before, ideally). This isn't really a huge deal and I doubt that the energy savings will every really pay for the pump, but I liked the idea of it, so there it is.

Also working is the RO/DI. The eventual plan is to swap out my current 6-stage system for a 7-stage setup. I've got everything I need to do that, but I still have a canister or two of 6-stage resin to use up. I reconfigured my lines a bit more to make it easier to turn the system on, however. I used to have to turn my booster pump on/off manually after opening the water up, but now it comes on automatically (using a pressure switch). I've had the switches in there for a while, they were just in the wrong place and I was too busy (read: lazy) to change them. All good now. I left in a manual diversion setup I use to manually flush the system. I've got TDS meters all over the place in that thing (9 total) and I've learned that the first few minutes of water - even after the auto-flush - comes in pretty high; in the 100+ range most times. It settles down into the 10-12 range after a few minutes, but that initial hit was resulting in far faster depletion than I get now. I may decide to use a few solenoids to handle all of that for me, but will likely hold off on that until there's a good way to measure TDS in real-time via the Apex. The goal is to balance saving water and resin; which I don't feel can be done well enough with clock-based assumptions. I may revisit that if I get bored, however (read: never - I have kids)... The other thing I changed about the RO/DI is that I'm no longer capturing my waste water. I feel horrible about this - I'm just dumping water down the drain whereas I used to fill the kids pool, water the lawn, clean out dirty tanks, etc. It was always slow and painful (see 1/2" pump woes above), but I felt like I was Doing Good, so that was okay. The problem is that in the new house, the fish room (and RO/DI station) will be in the middle of the house with no direct outside access. In the current house, I just ran out of room (more and more of which is being filled with boxes). Once in the new house, I'll look for a way to push a drain line outside so that I can capture it in a "rain barrel" or the like. But for now; down the drain it goes. **sigh**

The one major thing I broke was that I could no longer rely entirely upon gravity to power my ATO. I don't want to drill a low bulkhead into the clean water tank because I won't need it in the new house (that will use the PMUP-based ATO that's currently on the frag tank). So instead, I placed the new 10gal ATO container up on the top of the freezer and directed the existing ATO tube into it. Once I filled it up some, I drew from the other end to start a syphon. With that going, I hooked it back up to the ATO float in my current DT's sump and got back to ATO-ing. Only one problem: if the syphon breaks, the ATO stops working. In other words; if the tank runs dry, it's a pain to get going again. Not a huge one for me to do, but not something a house-sitter could do. And that's when it would go dry, of course... Not much I can do about that just yet. To make filling the tank easier, I ran some tubing up from the pump-out spigot into the ATO and left it in place. A few quick valve turns and the pump can fill the tank in a few seconds. That'll have to do for now (we go out of town this weekend).

That's where things are at right now. But there's more to come - oh so much more. The mixing tank has a temp and conductivity probe in it, hooked up to a PM2 module. I've got a DOS all set up with john guest fittings for an AWC setup and the mixing tank has a john guest bulkhead with a rigid drop-tube for a draw line. The mixing tank has a low-level sensor. The ATO also has a low-level sensor and I have one more for a top-level sensor. I added a flow sensor and solenoid to the main input of the RO/DI. There's an FMM module ready for all the sensors and such and all the modules have their aquabus cables and power cords.

Two things are missing, however:

1) A connection to the Apex system.

2) The water/drain lines for the AWC system.

Both of those require crawling under the house and running cabling/tubing. I've got the tubing and a length of CAT-6 wire, but am waiting on the USB connectors to build an "aquabus" cable long enough to span the distance needed. Once those arrive, I'll crawl under the house and hook it all up. Then - happy day! - no more manual water changes!!!

Oh man; the thought of that made me so happy. **sigh** Soon.

There's more to update on, but it's late and I've already written a novel tonight. I'll get some more details down, but here's a quick phone pic of the frag tank:

In short; it has it's own Apex now and I've been moving some corals over to get them into a QT. I picked up 2 clams during a live sale; one is doing well, the other not so well. I've not tested params in a few days, so I'm sure there are any number of things I could do to address the issue... That's for tomorrow (if work doesn't kill me, at least)...

7/25/18 - Day 0 (Still)

TL;DR - Still no tank. Still no house. Still no new build officially started...

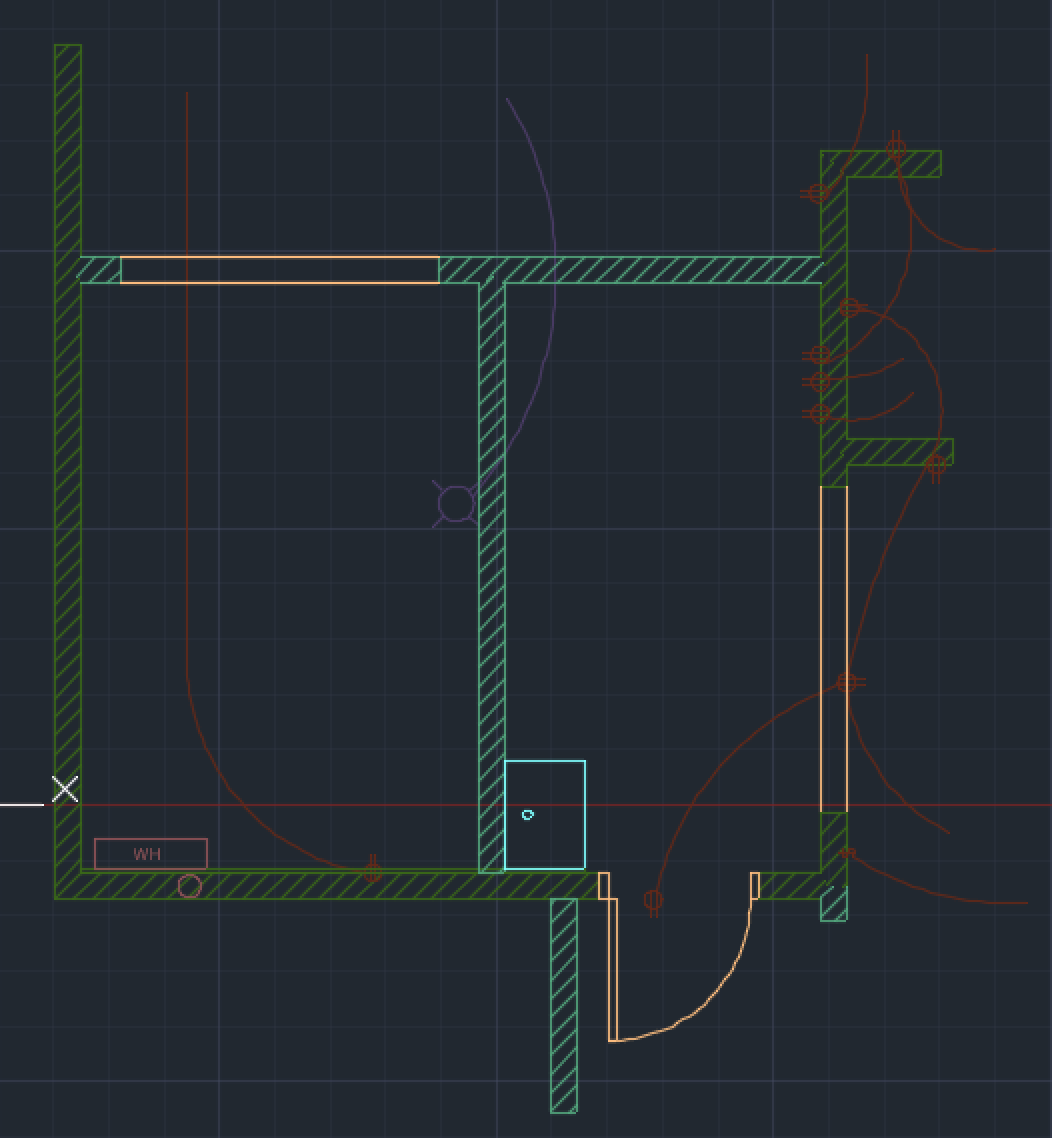

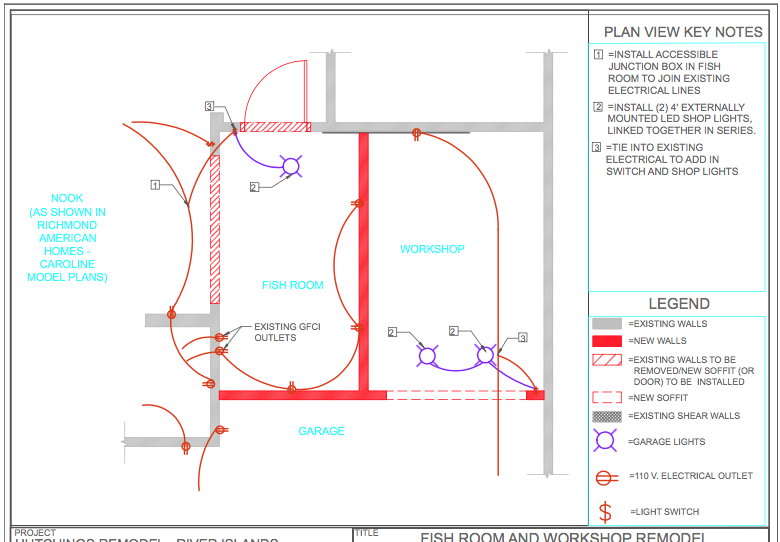

The house is coming along. We've been given a soft date of mid-September for when we take possession, so that's set in motion a bit of a scramble to sell the current house. Not much of one, really, but we would really like to have the current place sold and closed and us just starting a 30 (or 60) day rent-back when we take possession. That way, we have time to do all the construction (inside and out) that we want to/need to do. One challenge is that the new city has a really slow permit process. I've heard it's not uncommon to have a month delay for things like detached awnings (which wouldn't even need a permit most places)... :-\ I talked with the permit office and they don't see any reason why I couldn't submit my plans (and pay for them) and get them approved before we actually take over the house. They won't be able to actually issue the permit(s), but they'll be ready when we do become the owners and can pick them up very soon after. So that's what we're doing, I guess. Which means I have to convert my 3d "roughs" into an actual architecture diagram (complete with power, water, drain, etc.). I'm no pro, but I can manage the drafting required (assuming my trial of AutoCad doesn't end), so it's really just a matter of getting it done. Progress (some of the items are existing and will be removed):

To give you a sense of what this all actually looks like;

(With my dad in the background ... for scale?)

The wall you're looking through is where the tank will go. In the draft, it's the wall on the right. Obviously there's a plug that's going to need to be removed and re-wired. I asked the builder to change up the wiring to not run in serial into another area of the room, but they unhelpfully did not do that. So I'll have to splice together two ends just to keep the whole thing working... Ugh for even the little things being harder than they need to be.

Meanwhile, I've also been dealing with Tesla on the Powerwalls I want to install in the house. Despite the fact that I put myself onto their wait-list months ago specifically because I knew that inventory was low and getting one battery - let alone two - would take time, they declined to accept the order until I'm actually the owner of the house. That was a few months ago. When I called to follow up and give them the date when it should all go down, the guy basically laughed at me and told me that they were out of batteries and had no idea when they would get more in. (He was actually rather polite about the laughing at me - more like a "laughing with you, not at you" kind of thing.) Anywho; not counting on getting those any time soon. So instead, I called their support line today about uninstalling the one that I have here (and then installing it in the new house). That threw them for a loop. "Most people just leave them and sell them with the house." Cool story - I'm not most people. We'll see what they come back with. When I asked before, the answer I got was, "Oh yeah; you could do that, but WE don't do that - just hire an electrician." As if some random electrician with no knowledge of this thing could uninstall it... I was there when they put it in and I couldn't tell you how to unhook it without killing myself - or worse; ruining the battery! Really, I'm hoping that my request is so odd that they just decide to find me two new ones instead...

FISH STUFF!

Two new additions to the (future) tank; one to try and solve the aiptasia outbreak I've got going on, and another because shipping one fish is expensive:

(Sorry for the blue pics; I'll get better ones once everyone is in the new tank...)

My 4yr old daughter gets to name all our fish from here on out apparently, to the filefish has been dubbed "Zig Zag" while the Heniochus is "Zebra". Both fish came to me disease free and eating frozen food. I'm not sure if that's why I have enjoyed them from the start, or if it's just because they are such great tank additions. Zebra, in paticular, is a model fish for a reef tank - spends pretty much every moment up in the water column, cruising around and just being a fish in the water. If I could fill a tank with more like him, I very likely would... ZigZag is also fun, but not because he's easy to spot. Quite the opposite, in fact. He reminds me a lot of Sadness (from Pixar's Inside Out) - just mopes about the tank with his head down, doing his best to be ignored by everyone. It's quite enjoyable to see all the "bullies" of the tank zoom right past him chasing each other about. Good on ya', ZigZag!

Beyond that; I just got done moving the Frag tank. It kind of ended up sprawling all over the counter top and the wife was not happy with it being there for the open house. And since my office got basically gutted (it was the one room I couldn't defend us keeping anything in beyond my computer), the frag tank is now sitting next to me on the desk. It was a bit of a daunting task to move the tank, even with no fish involved. But good practice for the move to come...

I've lost the "not so well" clam and a few other pieces since the last picture (the other clam is doing fine still). I'm doing my best to keep everything alive, but I've not had the time to give it proper attention (what with all the house projects in prep of selling it, kids, work, ... yeah. Life.). Hopefully with it sitting right next to me, I'll be more inclined to take care of them. Tomorrow (or soon, at least), I'll pull out the last of the frags I intend to keep and start a fallow period. Figure I may as well really make sure that the new tank is disease free since I have to move everything anyways and if I start the coral QT now, they should be ready when the tank is up and running. The fish will all go through TTM - which will be fun, I'm sure. I'll likely do that at this house before we move so that I don't have tanks all over the house when we move in (make the wife happy and all that).

Speaking of which; the rock is all fully cycled in the brute cans. I picked up another 60lbs of "flat rock" to use as the base pieces, so that should really help form the aqua-scape when the time comes for that. I've been tossing in a small bit of food every month or so and give it some ammonia once a week-ish - enough to keep the bacteria from going totally dormant. I do expect I'll get a mini-cycle getting everything into the new tank, but hopefully it's brief and easily waited out. Patience, after all, is everything in this hobby. And buying a house, it seems...

TL;DR - Still no tank. Still no house. Still no new build officially started...

The house is coming along. We've been given a soft date of mid-September for when we take possession, so that's set in motion a bit of a scramble to sell the current house. Not much of one, really, but we would really like to have the current place sold and closed and us just starting a 30 (or 60) day rent-back when we take possession. That way, we have time to do all the construction (inside and out) that we want to/need to do. One challenge is that the new city has a really slow permit process. I've heard it's not uncommon to have a month delay for things like detached awnings (which wouldn't even need a permit most places)... :-\ I talked with the permit office and they don't see any reason why I couldn't submit my plans (and pay for them) and get them approved before we actually take over the house. They won't be able to actually issue the permit(s), but they'll be ready when we do become the owners and can pick them up very soon after. So that's what we're doing, I guess. Which means I have to convert my 3d "roughs" into an actual architecture diagram (complete with power, water, drain, etc.). I'm no pro, but I can manage the drafting required (assuming my trial of AutoCad doesn't end), so it's really just a matter of getting it done. Progress (some of the items are existing and will be removed):

To give you a sense of what this all actually looks like;

(With my dad in the background ... for scale?)

The wall you're looking through is where the tank will go. In the draft, it's the wall on the right. Obviously there's a plug that's going to need to be removed and re-wired. I asked the builder to change up the wiring to not run in serial into another area of the room, but they unhelpfully did not do that. So I'll have to splice together two ends just to keep the whole thing working... Ugh for even the little things being harder than they need to be.

Meanwhile, I've also been dealing with Tesla on the Powerwalls I want to install in the house. Despite the fact that I put myself onto their wait-list months ago specifically because I knew that inventory was low and getting one battery - let alone two - would take time, they declined to accept the order until I'm actually the owner of the house. That was a few months ago. When I called to follow up and give them the date when it should all go down, the guy basically laughed at me and told me that they were out of batteries and had no idea when they would get more in. (He was actually rather polite about the laughing at me - more like a "laughing with you, not at you" kind of thing.) Anywho; not counting on getting those any time soon. So instead, I called their support line today about uninstalling the one that I have here (and then installing it in the new house). That threw them for a loop. "Most people just leave them and sell them with the house." Cool story - I'm not most people. We'll see what they come back with. When I asked before, the answer I got was, "Oh yeah; you could do that, but WE don't do that - just hire an electrician." As if some random electrician with no knowledge of this thing could uninstall it... I was there when they put it in and I couldn't tell you how to unhook it without killing myself - or worse; ruining the battery! Really, I'm hoping that my request is so odd that they just decide to find me two new ones instead...

FISH STUFF!

Two new additions to the (future) tank; one to try and solve the aiptasia outbreak I've got going on, and another because shipping one fish is expensive:

(Sorry for the blue pics; I'll get better ones once everyone is in the new tank...)

My 4yr old daughter gets to name all our fish from here on out apparently, to the filefish has been dubbed "Zig Zag" while the Heniochus is "Zebra". Both fish came to me disease free and eating frozen food. I'm not sure if that's why I have enjoyed them from the start, or if it's just because they are such great tank additions. Zebra, in paticular, is a model fish for a reef tank - spends pretty much every moment up in the water column, cruising around and just being a fish in the water. If I could fill a tank with more like him, I very likely would... ZigZag is also fun, but not because he's easy to spot. Quite the opposite, in fact. He reminds me a lot of Sadness (from Pixar's Inside Out) - just mopes about the tank with his head down, doing his best to be ignored by everyone. It's quite enjoyable to see all the "bullies" of the tank zoom right past him chasing each other about. Good on ya', ZigZag!

Beyond that; I just got done moving the Frag tank. It kind of ended up sprawling all over the counter top and the wife was not happy with it being there for the open house. And since my office got basically gutted (it was the one room I couldn't defend us keeping anything in beyond my computer), the frag tank is now sitting next to me on the desk. It was a bit of a daunting task to move the tank, even with no fish involved. But good practice for the move to come...

I've lost the "not so well" clam and a few other pieces since the last picture (the other clam is doing fine still). I'm doing my best to keep everything alive, but I've not had the time to give it proper attention (what with all the house projects in prep of selling it, kids, work, ... yeah. Life.). Hopefully with it sitting right next to me, I'll be more inclined to take care of them. Tomorrow (or soon, at least), I'll pull out the last of the frags I intend to keep and start a fallow period. Figure I may as well really make sure that the new tank is disease free since I have to move everything anyways and if I start the coral QT now, they should be ready when the tank is up and running. The fish will all go through TTM - which will be fun, I'm sure. I'll likely do that at this house before we move so that I don't have tanks all over the house when we move in (make the wife happy and all that).

Speaking of which; the rock is all fully cycled in the brute cans. I picked up another 60lbs of "flat rock" to use as the base pieces, so that should really help form the aqua-scape when the time comes for that. I've been tossing in a small bit of food every month or so and give it some ammonia once a week-ish - enough to keep the bacteria from going totally dormant. I do expect I'll get a mini-cycle getting everything into the new tank, but hopefully it's brief and easily waited out. Patience, after all, is everything in this hobby. And buying a house, it seems...

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

And update to the build, thank you.

Exciting when it all comes together at once.

One of my favorite fish is my Matted filefish. My Niger trigger is also very cool with personality. The trigger and the filefish usually hang out together.

Exciting when it all comes together at once.

One of my favorite fish is my Matted filefish. My Niger trigger is also very cool with personality. The trigger and the filefish usually hang out together.

08/27/2018 - Day 0

TL;DR - Still a waiting game. Getting closer, though!

Long version;

We've sold our house. Got not only more than we were asking (not surprising), but more than we were expecting! Enough that we talked a bit about buying a rental property at some point in the future. But whether we do that or not, in the near-term we'll have enough funds to not worry about "the little things" (and that's on top of the ski boat and pilot's license already budgeted). I've decided that the fish room is a "little thing" (though the wife likely disagrees and would tell me to stay on-budget...).

The practical impact of this is that I went ahead and ordered the "dream stand" from 8020.net. Including the light rails*, the total thing ran a bit above $2k - which is MUCH higher than the wood stand I had planned would be. But I'm already liking the idea of a metal stand that is much more "sleek"

* - Light rails. I've gone ahead and ordered 2x 36" AquaticLife T5HO hybrids. To these I'll add the 4x G3 XR15's (with diffusers) I already have. I've no doubt that I'll be able to get enough light into the tank. To keep maintenance easy, I've designed out a couple of simple hanging rails with slides. Each light will be able to roll out of the way (hopefully) for access into the tank, bulb changes, etc. Since the lights will still be hanging off the crossbars, I'll be able to get them to the right height easy enough. Of the 8 bulbs I ordered along with the lights, 1 was bad. Once I get that one replaced, I'll start their burn-in so that they are ready to go.

The tank is built! It would have been delivered already, but that would mean moving it from the current house to the new one - which seemed silly. Instead I've asked Crystal Dynamics to store it and ship it up sometime next month directly to the new house. They charged me a small fee for storage (which was fine) and we'll sort out the exact ship date later. But all the pieces are coming together...

I've ordered about half the plumbing since it was on sale. The actual pipes (blue) will be through Amazon once we're in the new house (no reason to risk it being damaged in the move).

The new house will be ready for our initial walkthrough on Sept 11, after which the builder will have a week to fix things (if needed) and then we take possession on 9/18! We've got our current house through 10/14, so that gives us a few weeks for construction and such. For that, there are several projects...

- I've worked out with Tesla that they will uninstall the PowerWall we currently have and re-install it at the new location. Not sure on the timelines just yet, but they know about the 10/14 date. Odds are that it'll be uninstalled close to that, with some future date to install it in the new location. This will all cost me $2k; which is about what I expected. In case I've not mentioned it; I'd rather have 2 new batteries installed, but they are out-of-stock on them until Q2+ of next year. So I'll take what I can get and add another one (or two, if it makes sense) when I can.

- There is a bunch of landscaping we want done (concrete and fake grass, mostly) so that we can move our hot tub into position right away. Not (just) because I think having the hot tub will be nice after a day of construction, but because then I don't have to have friends come over to get it into position - the movers can do that.

- The fish room. We've submitted the plans to the city:

That's just one of the 8 pages of plans my wife worked up. She used to be a civil engineer and really geeks out on this kind of stuff. When we walked into the planning office with these, they asked to talk to our designer. We got to smile and tell them, "You are". We walked them through everything and basically got verbal approval on the project from the plan reviewer, so we don't expect any issues getting the permits - eventually. These were submitted on the 14th (~2 weeks ago) and we've not heard back from them. Not surprising (they are known to be slow), but something we'll have to stay on top of. The point we're looking for is for these to pass the "plan check" phase. We won't be able to actually pull the permits until we are the owners, but that should be possible the day we take possession. I've taken the first full week off from work, which should be more than enough time to get the above build-out done... I hope. :-]

I've done most of the "tear down" on the current tank. Only thing left in the tank I plan to keep is an ornery rock nem that refuses to let go, the large toadstool I'm afraid to try to move, and the fish. Once I get the last two corals out, I'll start the fallow clock on the frag tank. The fish will be trapped and moved into QT tanks sometime early Sept. I'm hoping to have a CP prescription by then, but if not, they'll all go through TTM. That'll be fun if I have to do it that way... I'll likely keep the existing tank up and running until very close to the end (or at least until the fish are through the CP/TTM process). That way if something does go sideways in the QT process, I can just return them to the well-established DT to recover from whatever and start the QT over later on...

TL;DR - Still a waiting game. Getting closer, though!

Long version;

We've sold our house. Got not only more than we were asking (not surprising), but more than we were expecting! Enough that we talked a bit about buying a rental property at some point in the future. But whether we do that or not, in the near-term we'll have enough funds to not worry about "the little things" (and that's on top of the ski boat and pilot's license already budgeted). I've decided that the fish room is a "little thing" (though the wife likely disagrees and would tell me to stay on-budget...).

The practical impact of this is that I went ahead and ordered the "dream stand" from 8020.net. Including the light rails*, the total thing ran a bit above $2k - which is MUCH higher than the wood stand I had planned would be. But I'm already liking the idea of a metal stand that is much more "sleek"

* - Light rails. I've gone ahead and ordered 2x 36" AquaticLife T5HO hybrids. To these I'll add the 4x G3 XR15's (with diffusers) I already have. I've no doubt that I'll be able to get enough light into the tank. To keep maintenance easy, I've designed out a couple of simple hanging rails with slides. Each light will be able to roll out of the way (hopefully) for access into the tank, bulb changes, etc. Since the lights will still be hanging off the crossbars, I'll be able to get them to the right height easy enough. Of the 8 bulbs I ordered along with the lights, 1 was bad. Once I get that one replaced, I'll start their burn-in so that they are ready to go.

The tank is built! It would have been delivered already, but that would mean moving it from the current house to the new one - which seemed silly. Instead I've asked Crystal Dynamics to store it and ship it up sometime next month directly to the new house. They charged me a small fee for storage (which was fine) and we'll sort out the exact ship date later. But all the pieces are coming together...

I've ordered about half the plumbing since it was on sale. The actual pipes (blue) will be through Amazon once we're in the new house (no reason to risk it being damaged in the move).

The new house will be ready for our initial walkthrough on Sept 11, after which the builder will have a week to fix things (if needed) and then we take possession on 9/18! We've got our current house through 10/14, so that gives us a few weeks for construction and such. For that, there are several projects...

- I've worked out with Tesla that they will uninstall the PowerWall we currently have and re-install it at the new location. Not sure on the timelines just yet, but they know about the 10/14 date. Odds are that it'll be uninstalled close to that, with some future date to install it in the new location. This will all cost me $2k; which is about what I expected. In case I've not mentioned it; I'd rather have 2 new batteries installed, but they are out-of-stock on them until Q2+ of next year. So I'll take what I can get and add another one (or two, if it makes sense) when I can.

- There is a bunch of landscaping we want done (concrete and fake grass, mostly) so that we can move our hot tub into position right away. Not (just) because I think having the hot tub will be nice after a day of construction, but because then I don't have to have friends come over to get it into position - the movers can do that.

- The fish room. We've submitted the plans to the city:

That's just one of the 8 pages of plans my wife worked up. She used to be a civil engineer and really geeks out on this kind of stuff. When we walked into the planning office with these, they asked to talk to our designer. We got to smile and tell them, "You are". We walked them through everything and basically got verbal approval on the project from the plan reviewer, so we don't expect any issues getting the permits - eventually. These were submitted on the 14th (~2 weeks ago) and we've not heard back from them. Not surprising (they are known to be slow), but something we'll have to stay on top of. The point we're looking for is for these to pass the "plan check" phase. We won't be able to actually pull the permits until we are the owners, but that should be possible the day we take possession. I've taken the first full week off from work, which should be more than enough time to get the above build-out done... I hope. :-]

I've done most of the "tear down" on the current tank. Only thing left in the tank I plan to keep is an ornery rock nem that refuses to let go, the large toadstool I'm afraid to try to move, and the fish. Once I get the last two corals out, I'll start the fallow clock on the frag tank. The fish will be trapped and moved into QT tanks sometime early Sept. I'm hoping to have a CP prescription by then, but if not, they'll all go through TTM. That'll be fun if I have to do it that way... I'll likely keep the existing tank up and running until very close to the end (or at least until the fish are through the CP/TTM process). That way if something does go sideways in the QT process, I can just return them to the well-established DT to recover from whatever and start the QT over later on...

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

Very cool.

09/07/2018 - Day 0

Still waiting, but it's getting close!

We've got our initial walk-through next Tuesday (9/11). The builder will have a week to fix anything we find and we should close on 9/18. Then the fun begins...

We're still working out the order of operation on the build. I think the order will be;

1) Get the tank delivered and moved into the house somewhere out of the way, but easy to get to (don't want to have to carry it around the garage and through the house, but also don't want to have the kids climbing in it)

2) Build the new walls (electricity, plumbing, etc.)

3) Cut out the opening, install the new door

4) Pour the concrete "step" for the back half of the tank (will take 1wk to dry and cure)

5) Initial inspections

6) Insulate and close up all the walls

7) Final inspections

8) Build the stand and install the tank

9) Plumbing & electrical on the DT and Frag

10) Scape and fill with water

11) Mini-cycle (rocks in tubs are already cycled; just recovering from the move and such)

12) Fill with livestock!

13) Build "presentation" side of wall (shiplap or the like - still TBD, though we have some boards we'll likely use we got on sale recently)

14) Fin! (see what I did there?)

Looking at all that, I doubt very much that it'll all get done before 10/11 (which is our move-out date for the current house). Which means that the fish and corals will have to exist in temporary tanks somewhere in the new house (likely my office). I'm planning on putting all the fish through TTM QT (because why not at this point), so I'll likely wait till we're in the new house for that to start. I'd rather do CP QT instead (easier), but I've never done that method and I don't think I'll have the mental ability to deal with something new. At least with TTM, it's something I'm set up for and have experience with... Corals are already in QT; 67 more days on them...

In addition to all the above tank-specific stuff, there is also:

a) Moving the PowerWall. I'm going to be another "first" for Tesla as I've asked them to move my current PowerWall from the old house to the new one. This is because they are backlogged on new units until Q2 of next year (at best). So rather than wait for that, I'll move this one. Will cost me $2k (their normal install is $1k+), but that will also restore the solar hookups at the old house (something that would run me $500-800 for someone else to do). Ideally, I'd like that installed as soon as possible so that the interconnection process can get done before we move in. Tesla is on-the-ball on this one; they seem to have plans in place with the city and are standing by to schedule a work date once we are the official owners.

b) Concrete in the backyard, etc. We've got a guy who will be installing the concrete patio in our backyard - also required pre-move since we have a hot-tub to move and need somewhere to put it. He's offered to pour the step (#4) for me as part of the overall cost, which is nice. Challenge there is that his schedule isn't the fastest (we're getting his "side job" rate - ~50% off - but it means he only works on the weekends for us) - he's not scheduled to pour until 9/29 or so. Which means it won't be cured until 10/6. The step must be fully cured before I can start step 8 - which might be okay... The alternative is that I pour the concrete myself. Which is not all that big a deal, but still - free concrete at no effort by a pro versus me paying for concrete and pouring it myself (the wife was a civil engineer, so we have the know-how in-house; it's just the "doing it" part)... Likely just let him do it.

c) Installing a water softener. Measured the water in the new house and it's around 570 TDS (really bad). According to the stats of the system we are installing, the final TDS post-softener should be around 100-150 TDS - which is ~1/3 what I have now. During the move, I'll be switching from a 6-stage to a 7-state RO/DI setup, so if I have to mix up saltwater before the softener goes in, I expect to be able to handle it. My goal is to get it installed before moving anything over, however - so sometime before step 10 above. Before they can install the softener, however, I have to re-plumb the way that the main line connects to the house. I want to install a Buoy whole-house water meter to measure everything except the fire suppression system (which I don't want to mess with for obvious reasons), but to do that I will have to re-route not only the house water, but also the irrigation for the front and back yard. That has to be done before the softener can go in because I need to provide them with a loop to tie into. All of that plumbing has to happen before the concrete is poured. The softener is supposed to also sit on a concrete shelf - which means it can't be installed until after the concrete is cured. UGH. I may just have them install it onto a stack of pavers and pour concrete around it...

d) Internet. That's key, of course. Since I work from home as a programmer, I need higher-than-normal service, so I use Comcast Business for my internet. I've been happy with them, all-in-all. They recently notified me that my current hardware was out-of-date, so they were going to replace it a few weeks ago. I talked them into just installing the new equipment at the new house and leaving the old gear at the current house until we move out. Should give us a transition period where we have dual-location service. Which is nice.

e) Dog doors and runs. We have two dogs. They fight - to the tune of $3k in emergency medical bills over the past few years. So we keep them apart now. At the current house, we have sub-divided the backyard and installed gates at points throughout the house. We have to do the same at the new house - cut two dog doors into the walls to the outside, install standard gates outside, and get fake grass put down (no real grass at the new house - too hard to keep up). However, because of the house layout and larger hallways sizes (which is very nice), we won't be able to use standard dog gates. We've come up with a solution that involves building two custom "cabinets" with swing-out gates (one for day-time when one dog can be located downstairs with me in the office, the other to separate them at night when they both need exterior access). I'm not sure when exactly we'll build those, but it will likely be soon after we take possession - which will take my time away from all the tank-related stuff.

f) As mentioned, moving day is 10/11. We're leaving it loose on when we'll start actually living in the new house, but we figure that it will be before the movers, but after the internet, dog runs, and step 6 above...

g) A few other things to do - replace all the drawer slides in the kitchen with soft-close, remove the stove (and cabinet underneath it) and replace it with a high-end one, install surround-sound into the living room, fix all the switched plugs in the house (how I hate those...), and a slew of other minor things that will likely be "first year" projects instead of "pre-move-in" projects...

Sorry for the ramble. Things are getting closer and closer and the tasks are mounting up. I'm looking forward to the time when I (we) can start to actually finish things. While it's important, crossing off the "scheduled installer" tasks aren't really feeling like it's getting anything done...

To finish on a fish-related note; I've gone ahead and increased the size of the project by picking up a beast of a UV sterilizer. The 2" ports means I'll have to convert from the 1.25" I'm planning on as my return up to the 2", then back down to split it off to the returns. I'm not sure if it would be better to have more of the lines actually be 2", however... Thoughts?

I'm also planning on hooking both COR20 pumps I have to the same return line (rather than to have one as the return for the DT and the other for the Frag). That setup should not only increase my return flow a great deal (good for the Triton method I'll be using once the tank is up and running), but will also give me a "touchless" backup in case of a pump failure. I figure I'll need to put a check-valve on each pump in order to make that work, but that shouldn't be hard to fit into the layout... I hope. :-|

Still waiting, but it's getting close!

We've got our initial walk-through next Tuesday (9/11). The builder will have a week to fix anything we find and we should close on 9/18. Then the fun begins...

We're still working out the order of operation on the build. I think the order will be;

1) Get the tank delivered and moved into the house somewhere out of the way, but easy to get to (don't want to have to carry it around the garage and through the house, but also don't want to have the kids climbing in it)

2) Build the new walls (electricity, plumbing, etc.)

3) Cut out the opening, install the new door

4) Pour the concrete "step" for the back half of the tank (will take 1wk to dry and cure)

5) Initial inspections

6) Insulate and close up all the walls

7) Final inspections

8) Build the stand and install the tank

9) Plumbing & electrical on the DT and Frag

10) Scape and fill with water

11) Mini-cycle (rocks in tubs are already cycled; just recovering from the move and such)

12) Fill with livestock!

13) Build "presentation" side of wall (shiplap or the like - still TBD, though we have some boards we'll likely use we got on sale recently)

14) Fin! (see what I did there?)

Looking at all that, I doubt very much that it'll all get done before 10/11 (which is our move-out date for the current house). Which means that the fish and corals will have to exist in temporary tanks somewhere in the new house (likely my office). I'm planning on putting all the fish through TTM QT (because why not at this point), so I'll likely wait till we're in the new house for that to start. I'd rather do CP QT instead (easier), but I've never done that method and I don't think I'll have the mental ability to deal with something new. At least with TTM, it's something I'm set up for and have experience with... Corals are already in QT; 67 more days on them...

In addition to all the above tank-specific stuff, there is also:

a) Moving the PowerWall. I'm going to be another "first" for Tesla as I've asked them to move my current PowerWall from the old house to the new one. This is because they are backlogged on new units until Q2 of next year (at best). So rather than wait for that, I'll move this one. Will cost me $2k (their normal install is $1k+), but that will also restore the solar hookups at the old house (something that would run me $500-800 for someone else to do). Ideally, I'd like that installed as soon as possible so that the interconnection process can get done before we move in. Tesla is on-the-ball on this one; they seem to have plans in place with the city and are standing by to schedule a work date once we are the official owners.

b) Concrete in the backyard, etc. We've got a guy who will be installing the concrete patio in our backyard - also required pre-move since we have a hot-tub to move and need somewhere to put it. He's offered to pour the step (#4) for me as part of the overall cost, which is nice. Challenge there is that his schedule isn't the fastest (we're getting his "side job" rate - ~50% off - but it means he only works on the weekends for us) - he's not scheduled to pour until 9/29 or so. Which means it won't be cured until 10/6. The step must be fully cured before I can start step 8 - which might be okay... The alternative is that I pour the concrete myself. Which is not all that big a deal, but still - free concrete at no effort by a pro versus me paying for concrete and pouring it myself (the wife was a civil engineer, so we have the know-how in-house; it's just the "doing it" part)... Likely just let him do it.

c) Installing a water softener. Measured the water in the new house and it's around 570 TDS (really bad). According to the stats of the system we are installing, the final TDS post-softener should be around 100-150 TDS - which is ~1/3 what I have now. During the move, I'll be switching from a 6-stage to a 7-state RO/DI setup, so if I have to mix up saltwater before the softener goes in, I expect to be able to handle it. My goal is to get it installed before moving anything over, however - so sometime before step 10 above. Before they can install the softener, however, I have to re-plumb the way that the main line connects to the house. I want to install a Buoy whole-house water meter to measure everything except the fire suppression system (which I don't want to mess with for obvious reasons), but to do that I will have to re-route not only the house water, but also the irrigation for the front and back yard. That has to be done before the softener can go in because I need to provide them with a loop to tie into. All of that plumbing has to happen before the concrete is poured. The softener is supposed to also sit on a concrete shelf - which means it can't be installed until after the concrete is cured. UGH. I may just have them install it onto a stack of pavers and pour concrete around it...

d) Internet. That's key, of course. Since I work from home as a programmer, I need higher-than-normal service, so I use Comcast Business for my internet. I've been happy with them, all-in-all. They recently notified me that my current hardware was out-of-date, so they were going to replace it a few weeks ago. I talked them into just installing the new equipment at the new house and leaving the old gear at the current house until we move out. Should give us a transition period where we have dual-location service. Which is nice.

e) Dog doors and runs. We have two dogs. They fight - to the tune of $3k in emergency medical bills over the past few years. So we keep them apart now. At the current house, we have sub-divided the backyard and installed gates at points throughout the house. We have to do the same at the new house - cut two dog doors into the walls to the outside, install standard gates outside, and get fake grass put down (no real grass at the new house - too hard to keep up). However, because of the house layout and larger hallways sizes (which is very nice), we won't be able to use standard dog gates. We've come up with a solution that involves building two custom "cabinets" with swing-out gates (one for day-time when one dog can be located downstairs with me in the office, the other to separate them at night when they both need exterior access). I'm not sure when exactly we'll build those, but it will likely be soon after we take possession - which will take my time away from all the tank-related stuff.

f) As mentioned, moving day is 10/11. We're leaving it loose on when we'll start actually living in the new house, but we figure that it will be before the movers, but after the internet, dog runs, and step 6 above...

g) A few other things to do - replace all the drawer slides in the kitchen with soft-close, remove the stove (and cabinet underneath it) and replace it with a high-end one, install surround-sound into the living room, fix all the switched plugs in the house (how I hate those...), and a slew of other minor things that will likely be "first year" projects instead of "pre-move-in" projects...

Sorry for the ramble. Things are getting closer and closer and the tasks are mounting up. I'm looking forward to the time when I (we) can start to actually finish things. While it's important, crossing off the "scheduled installer" tasks aren't really feeling like it's getting anything done...

To finish on a fish-related note; I've gone ahead and increased the size of the project by picking up a beast of a UV sterilizer. The 2" ports means I'll have to convert from the 1.25" I'm planning on as my return up to the 2", then back down to split it off to the returns. I'm not sure if it would be better to have more of the lines actually be 2", however... Thoughts?

I'm also planning on hooking both COR20 pumps I have to the same return line (rather than to have one as the return for the DT and the other for the Frag). That setup should not only increase my return flow a great deal (good for the Triton method I'll be using once the tank is up and running), but will also give me a "touchless" backup in case of a pump failure. I figure I'll need to put a check-valve on each pump in order to make that work, but that shouldn't be hard to fit into the layout... I hope. :-|

9/27/2018 - DAY 1

The build has officially begun!

We got the keys to the new house on the 19th. It's been a crazy week since then... Because we are moving our hot tub, we need to get concrete poured before we move. And that takes ~1wk after it's poured to cure/set, so that was the first thing we needed to get done (yes; before even the fish tank). Okay; the FIRST thing we needed to get done was to get the internet hooked up - that happened on the 20th. Then it was the concrete. We had actually lined up a guy to do the work, but after a week of watching him get next-to-nothing done, we fired him and brought in someone new. That was a few days ago and they have since been jamming. Part of the concrete project, however, was figuring out where the turtle pond/waterfall would go and how it would be constructed (the concrete will be poured up to the base of the pond). We started with one idea (cinder blocks faced with rock) but decided that was too much of a pain, so switched to more conventional retaining wall bricks. That led to a round of "what color should this all be" (which involved the concrete people again). We eventually got that all sorted out and the wife started building that (I've got a picture, but I'm not allowed to share it as she thinks it's less-than-flattering... I'll get one sans lovely wife later). Meanwhile, we discovered that even if we had the concrete poured, the hot tub wouldn't fit past the gas main on the side-yard that has the gate. Even deconstructing the gate, it's an inch or so too narrow. The hot tub movers may be able to manhandle it past, but I'm not counting on it. So the second priority of building dog gates to keep the dogs apart (they fight) on the other side of the house was put on hold so that we have the option of bringing the hot tub down that side (where - once the front fence is removed - there is plenty of room). All that meant that we can't do a "soft move" where we live in the new place while our stuff slowly transitions over. That has meant hours lost driving between the places and no ability to work on projects into the night. Boo. Still; I perceiver...

Because we have kids (4yrs and 2yrs), we had to set up things to entertain them if we wanted to get anything at all done. So a portion of one day was spent buying and installing a new TV. Not the worst thing in the world to have to do, but it wasn't on the critical path to a fish room...

Then there was the power lines for the hot tub that had to be run before the concrete could be poured. Which required renting a trench digger because there's no way I was going to dig an 18" deep, 30ft+ trench. And since I had the trencher ($220 a day), I went ahead an dug out water lines, an extra conduit line for under the concrete (because that's something I always end up needing), and the electrical line for the pond (12" deep, 20ft+). All-in-all, I got my money's worth on that rental (just wish it hadn't leaked oil in my brand new garage, but oh well...). Still; that took a few days to get all sorted out. But at least we have a hard water line run to the backyard (the builder-installed hose bibs are all going to be soft-water), which will allow me to water the plants and fill the hot tub with that water (along with washing off the deck and other such needs that I don't want to pay extra for).

At this point in my saga, you'll note that I've still not mentioned the fish room. Hold true, dear reader - it'll get better. Just not yet...

Around this time, I was informed that the tank would not be delivered on time. Due to the Starfire glass shortage (that's a thing), the builder didn't have enough inventory to load into a truck and make worth the drive from San Diego to NorCal. Totally fair - margins are slim and I don't begrudge anyone for trying to stay in business. I would have had the tank in-hand already had I not delayed it for want of not wanting it to have to be moved. So now instead of a delivery that should have happened already, the date I was given was the weekend after we moved in. Which makes it pretty hard to finish the fish room build before we move in - much less have all the fish in the tank soon after. After a bit of emails, we sorted out that there's a shipping company that can handle getting it up here next week. I've no idea what it'll cost me nor where the tank will end up (from whence I shall have to go an get it with a truck). Nor do I really know how I'll get said tank from the truck into the house. And I don't even want to think about the potential for damage to the tank... **shudder** I've basically tossed the dice on that side of things and just hope that things don't come up with the wrong number of pips.

Fridge got delivered, but they didn't have the right hose. Washing machine won't be delivered until we get a metal catch pan, because the plastic one clashes with the curtains or something (they break a lot, says the sales rep...). Metal catch pans aren't something you find a Home Depot ("we carry plastic ones", they say, without the slightest idea of how much sense that makes to me), so we have to have one "custom" fabricated at a sheet metal shop. But at least they tack-welded on a copper drain fitting for free? The delivery people won't hook up the gas line to the dryer (liability), so I get to do it. But they forgot the right size hose (what is it with them and hoses?!?), so that took me two tries. There's been a slew of car break-ins in the area (new construction; happens), so the wife asks me to prioritize getting an alarm system and cameras installed (hired a guy who is doing good work, but is also very chatty).

And STILL no work on the fish room. It's getting tedious, this lack of progress - right? So yeah; that's about where I'm at on Thursday when I just tell everyone to leave me alone - I'm going to go pull permits for the project. Somehow, this is less painful that expected. Things go smoothly and I walk out of the permit office with a Project Sheet! That one piece of blue card stock is like my Golden Ticket to happy reefing. Or so I like to tell myself in between sobs of exhaustion...

SO. Picture time. Here's the before angles:

Main wall, interior

Pretty boring, eh? Needs more water, you think? Me too.

This will be the door into the fish room. I hope - still yet to find a door and it seems like no one inventories 8ft doors around here... May introduce a 10-day delay. :-\

Definitely boring. Needs more door.

Here's the garage side of things. This will eventually be the fish room and workshop space:

The "Utilatub" will be my slop sink and the long boxes laying down against the wall are my 80/20 stand and light rails. I really should find time to open those up and assemble the stand in case there are any parts missing/needed... :-\

The other long box is my roll of neoprene for under the tank. No idea why it's just laying there like someone threw it into the corner. Likely because I threw it into the corner and forgot about it...

The other side of the fish tank wall.

Here you see the two dedicated circuits I had the builder add (GFCI outlets). They are totally in the wrong position. But after pointing where I wanted them and discovering them moved somewhere else, I just gave up. I'm opening up that wall anyways and can move them later.

The other plug was specifically requested not to be included there. They added it anyways. Because... reasons. Whatever; removal is easy.

Finally, the network plug. Because when you're building a new house, you can hard-wire everything (if you pay enough to have that done, of course).

AND WE'RE OFF!

The day after I picked up the permit (9/26), I officially started the project by demo-ing what I had time for - which wasn't much. I did get some of the lines measured, chalked, and cut in. Then I started pulling down drywall chunks. Interestingly, I discovered that the sheetrock crew had just covered up all the construction plans that were on the wall rather than remove them. In their defense, there were like 30 staples in each piece of paper...

I was granted a bit more time to work on demo the next day. Managed to get enough torn out that I can build up the walls. I will need to tear out some more when it comes time to run plumbing and electrical, but I figure I can do that as needed once I'm ready to do so.

This was taken after clean-up, but before pulling all the nails and screws. MAN what a job that was. An individual nail or screw isn't that bad, but a few hundred - with a number of them being over your head - really makes you tired. Or made me tired, at least. I didn't snap a picture of the nail-less/screw-less state. It's like the above, just without as many nails and screws in the studs.

Finally; it's time to build some walls! Or a wall, at least:

I'm including this picture to illustrate my "work clothes" for this project include my new R2R shirt! Okay; they don't really - I have a whole pile of work clothes I use, depending upon what I'm doing ("dirt jeans", "attic long sleeve", "gardening shoes", etc.) and "building fish room shirt" is actually not one of them, but I do have "general construction" gear. I just forgot to change. So - yes; I do sport my R2R apparel at random times. My outfits are pretty much Cubs, Disney, or R2R, in fact...

Also including this picture because it's a non-flattering pose and this post needs that.

The first wall is complete!

My method here, in case you would like to judge me on this is to use the most difficult method possible. Because of course it is - I'm a reefer, after all! ;-)

Most of my construction experience stems from high school when I was part of the tech crew for the drama club. This meant that it was my job to hang lights, build sets, and move things about the stage when it's dark between scenes. It was a pretty sweet gig - our crew (of two) had a "green room" where we got to store everything not currently in use. It was a pretty good sized room and we discovered that by organizing the stuff in a certain way, we were able to create a little "sitting area" that was no obvious unless you knew how to get to it. In this area we added a TV and game console (SNS, to date myself some there), mini fridge (stocked from the teacher's lounge because of course we had keys), and couch. Because only the two of us knew about the "crash pad", we would hang out in there during lunch and other free times - playing video games and such instead of socializing with Other Kids. As I said; it was a sweet gig - up until the drama teacher decided I should be ON stage instead of BEHIND it and gave me a lead role in a play Junior year. For the remained of high school I was "front of house" and - correctly - thus no longer allowed into the "back of house" crash pad.

Whoa - tangent! My point is that I started construction in high school building temporary walls. Or walls that needed to be highly movable, but also extremely durable. That experience plus two years or architectural drafting gave me confidence to build my first actual wall years ago. I didn't find it overly difficult; just need to take it slow and measure a lot.

So, of course, I rushed through this project and mostly just eye-balled everything. It seems to be working out so far...

Okay; not really. I've chalked up all my lines, so I know everything will be as square and level as I can make it given the slab I'm working on is sloped for drainage. As you can see above, I've tacked up the top boards of the upper sill. I'm building the walls on the ground so that I don't have to toenail things in (I hate toenailing things - not sure why...). Then I stand them up and knock them into vertical before tacking the two layers of the upper sill together.

Our plans call for the bottom boards to be bolted to the floor. I've got all the parts for that, but we've hit a snag. The concrete foundation is a post-tension slab. This means that there are cables running through the slab that have been cranked tight in order to keep the concrete from breaking apart in an earthquake or the like, but also allowing them to shift some so that the normal settling of the ground doesn't cause as many cracks and such (at least; that's as much about the why-for's I listened to/retained). Point being - there are taught steel cables running through our slab - one every ~24" in each direction. We're not totally sure, but it appears that there is one running near enough to directly under not just one of the new walls - but both of them. :-\ There is no way that I'm going to drill down into the slab if there's any chance of hitting one of those cables, so we've called the builder's supervisor (good guy; we know him well at this point) to come out and give us his take on how close we are to them. We need to set a 5.25" long bolt through the bottom plate (standard 2x4 - so 1.5" deep board), so we'd need to drill into the concrete about 4". So either the cables being more than 4" deep OR them being offline means that we're good to drill. Otherwise we'll look at getting some tie-downs that we can use to offset the bolts to one side or the other... And then just hope that the inspector doesn't give us issues...

Today (Sunday, 9/30) I was actually able to get the other wall assembled while the grandparents watched the kids and the wife went to Ikea. I didn't get a picture, however, because (a) I forgot and (b) it didn't look all that impressive laying on the ground. :-|

Back at the old house for the night. Our hot tub gets moved tomorrow - we're having pros move it from the old house to the new one, placing it onto some plywood boards in the dirt since the concrete isn't even poured yet. We'll have to "hire" some friends (read: buy beer) to come over and help us move it into position once the concrete is set. While the crew is doing their thing at the new house, I hope to lift the wall into position. I took last week off work, but don't think I can beg off another week what with deadlines piling up. Luckily, I work remotely, so I'm hoping I'll still be able to progress on "the fish room project" (there are a surprising number of random people in town who know about this project and are looking forward to seeing the result) in between meetings and getting stuff done that actually pays the bills...

T-minus 11 days until the old house is moved over and I need to move the existing tank. My goal has shifted from "finish the build" to "be able to make saltwater". If I can get the latter, I figure I can keep all the fish and coral alive for long enough to actually finish the build... So I have 11 days to find a way to make saltwater. At the moment, that's effectively blocked by not having the water softener installed - the TDS of the tap water is something like 500 or so. (I've not measured it specifically, but the water softener guy measured the water during the consultation and it was stupid high - napkin math gave us a TDS of around 520 pre-softener, with around 80 expected post-softener (though that's got a wide swing given all the variables, ya-da, ya-da). There's a whole sediment and carbon block in the softener, so I expect I'll get better results from my RO/DI system than I am now - and that's not even accounting for the upgrade from a 6-stage to a 7-stage...

I'll try to keep the updates coming in the days ahead. Next major milestone is when all the framing is done. Or passing that inspection, I suppose...

The build has officially begun!