Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Random Flow Generator issues

- Thread starter drukkosz

- Start date

- Tagged users None

Users Who Are Viewing This Thread (Total: 1, Members: 0, Guests: 1)

Yes, reach out to them. Their customer support is great!

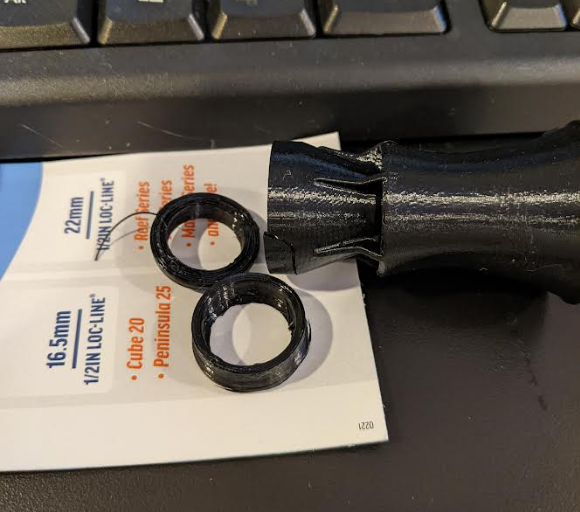

Yes they are, why not surprised?Wow... They look 3d printed to me... if so, not surprised they are failing.

I've had this issue now with 4 of them, I really like them but I just stopped buying them, plus the last time I bought a replacement it didn't even come close to fitting the loc line (too loose) It's a shame because its a great idea but the need some more R&D on these.

- Joined

- Oct 3, 2019

- Messages

- 720

- Reaction score

- 730

From the pictures you can clearly see layer separation at the cut. These snap onto an existing line which will apply constant pressure to the part. PETG is relatively strong, but layer adhesion issues still can't be ignored. Which is what I think is happening here.Yes they are, why not surprised?

Gotcha, I've had 1 for about 2 years. Loose, but still able to direct it. I would glue that to a loc-line piece and still use it. Actually, epoxy would work better.From the pictures you can clearly see layer separation at the cut. These snap onto an existing line which will apply constant pressure to the part. PETG is relatively strong, but layer adhesion issues still can't be ignored. Which is what I think is happening here.

- Joined

- Oct 3, 2019

- Messages

- 720

- Reaction score

- 730

"Loose" is the key here. It needs to fit perfectly and be a little loose so that there is no pressure on the joint.Gotcha, I've had 1 for about 2 years. Loose, but still able to direct it.

From just this thread it seems that either the size of the part varies greatly from print to print or the size of the line is not uniform for everyone. You lucked out, others didn't.

Mine always ended up getting loose too. I also decided I didn't like putting so much back pressure on the return. Oh, I also didn't like that I had to run them so deep to prevent vortices that my sump would fill up way too much when I'd shut down the return. They do work well if you feed enough water to them.

Yup. I had an adapter split at the layer and the RFG nozzle crack right out of the package. Would love to see these produced with some better materials.

Last edited:

FYI I also reached out to vividcreativeaquatics. They were quick to respond and gave me a coupon code for a replacement.

They said: "it's pretty uncommon for the nozzle to crack in such a way as long as it's being connected to genuine Loc-Line, and since you're using one of our Kits, that should not be an issue"

Given the feedback I've seen on this site and elsewhere, I'm not certain that is the case. Perhaps we just got a bad batch? Either way, good customer service, and hope they mature materials used as I really like these on my small waterbox cube.

They said: "it's pretty uncommon for the nozzle to crack in such a way as long as it's being connected to genuine Loc-Line, and since you're using one of our Kits, that should not be an issue"

Given the feedback I've seen on this site and elsewhere, I'm not certain that is the case. Perhaps we just got a bad batch? Either way, good customer service, and hope they mature materials used as I really like these on my small waterbox cube.

Mine both cracked as well. I think you need to install them on the loc line ball as straight as possible and the same for removable so you don’t side load the female side.

Lot of people are not buying because of this. I have two on my tank but only been usong 3 months. If these break not gonna buy again.

Need better materials. Not 3d printed.

Need better materials. Not 3d printed.

I've had mine for 5 years now, snapped on and off many times over the years. Never had an issue with them.

Genuine 1/2" loc-line.

Genuine 1/2" loc-line.

You need to have a syphone break so it won't back feed to the sump.Mine always ended up getting loose too. I also decided I didn't like putting so much back pressure on the return. Oh, I also didn't like that I had to run them so deep to prevent vortices that my sump would fill up way too much when I'd shut down the return. They do work well if you feed enough water to them.

I believe @Vivid Creative Aquatics is a sponsor on here. Maybe they will chime into this thread now that I have tagged them.

Thank youI believe @Vivid Creative Aquatics is a sponsor on here. Maybe they will chime into this thread now that I have tagged them.

Similar threads

- Replies

- 6

- Views

- 89

- Replies

- 9

- Views

- 246

- Replies

- 5

- Views

- 144

TOP 10 Trending Threads

- Replies

- 21

- Views

- 370

- Replies

- 42

- Views

- 1,400

- Replies

- 98

- Views

- 1,373

- Replies

- 44

- Views

- 751

- Replies

- 36

- Views

- 320

- Replies

- 38

- Views

- 469

- Replies

- 33

- Views

- 803

- Replies

- 20

- Views

- 287

- Replies

- 71

- Views

- 1,438

Who Read This Thread (Total Members: 35)

- drukkosz

- antihackable

- aquamann

- badIuck

- bennyb

- Biochembob

- BritCJ51

- BrunoL

- capNemo

- CazadorMoreno14

- codenfx

- dannyboy92

- dgerstel

- Diederik

- drolmaeye

- DyrtyByrd

- homer1475

- JC Reef

- jmon22

- joanropi17

- kornface13

- Mark Hyman

- MizzouMark

- nkyreef

- Paul.martin

- Prooda

- Scryllarus

- thatotherblkguy701

- timvc

- tymo92

- umutcancamci

- Walkermtn540

- Wernerdin

- Zerodameaon

- Zreef