Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

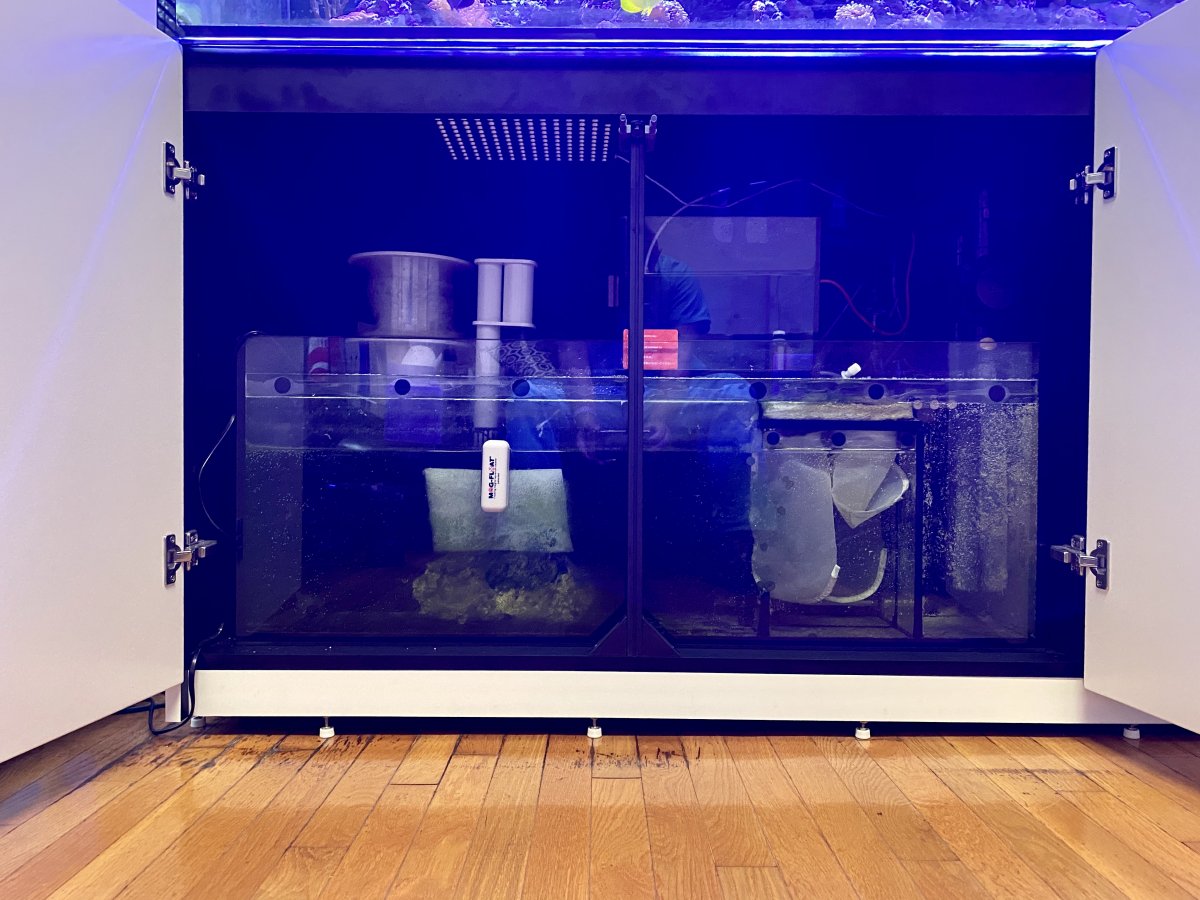

What's up with the recent Red Sea Tank failures? 750XXL ? *UPDATE* Design Flaw CONFIRMED by Red Sea !!!

- Thread starter Doostur

- Start date

- Tagged users None

- Joined

- May 6, 2019

- Messages

- 3,988

- Reaction score

- 7,900

Thanks for posting that glad they are.Red Sea WILL send replacement parts to people that have purchased the RSRxxl750 second hand as per the last line of this email I received..

Just to update this...

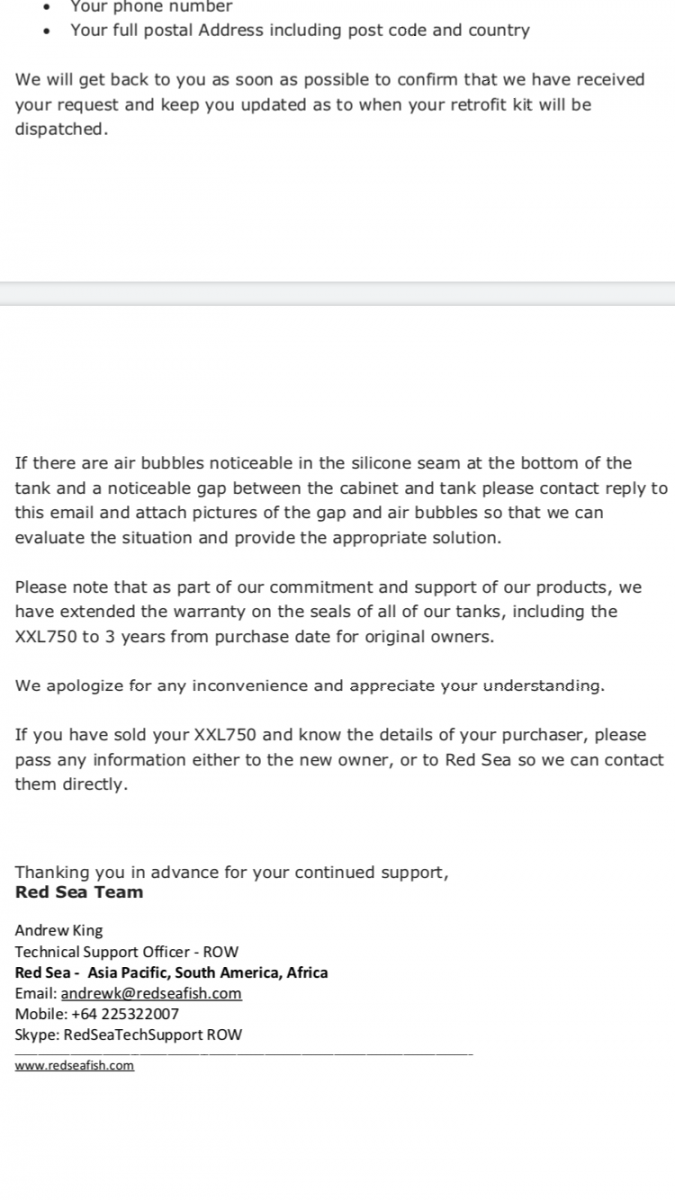

I received my retro fit kit today.

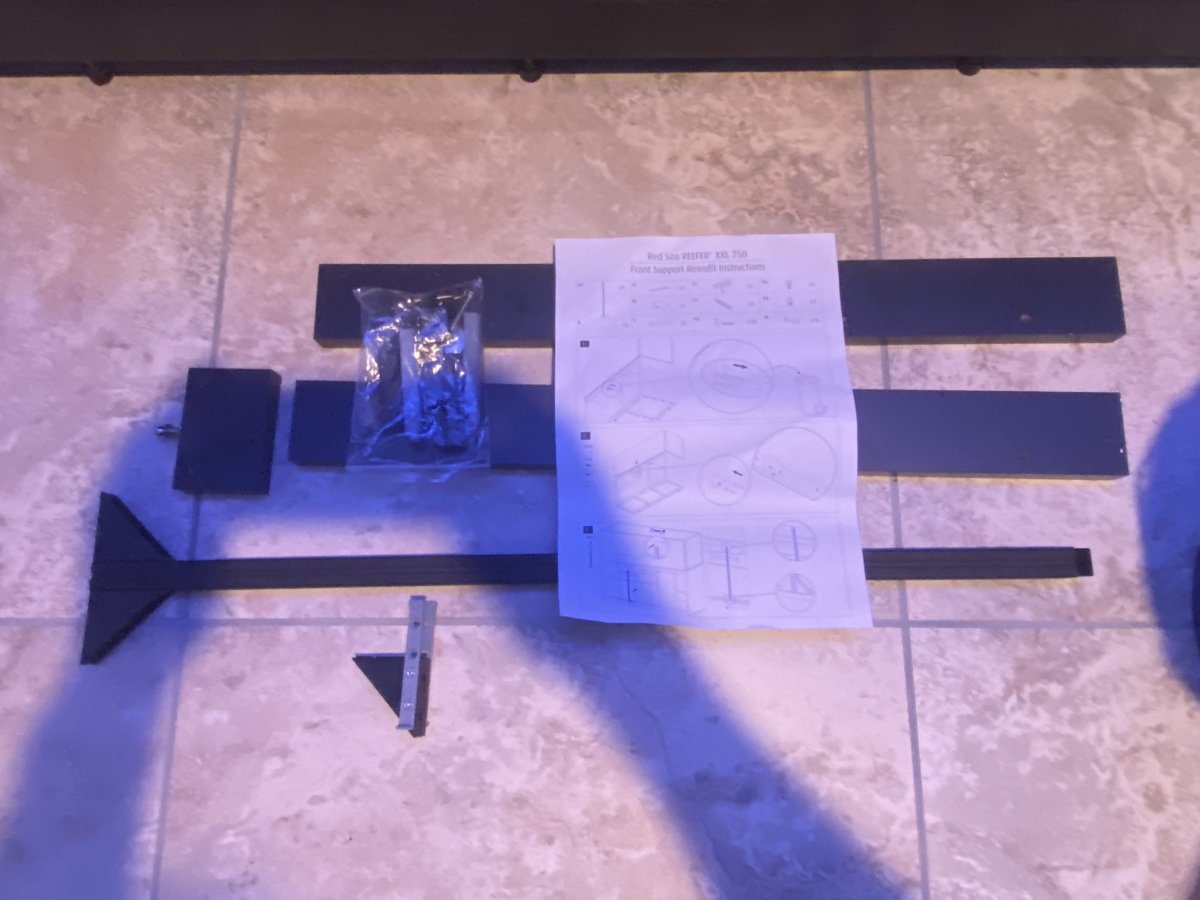

The long aluminum bar goes right in the middle of the sump area and I am not sure what the other two pieces are for, but they are made out of the same material as the stand. The way it is adjusted is by the rectangle piece with a steel ball that fits into the aluminum bar and is adjustable to get the stand pushed flush with the tank. I have not installed it yet, but will update my build thread when I do.

Just figured I would post this for people still waiting and wondering what the kit will include.

I received my retro fit kit today.

The long aluminum bar goes right in the middle of the sump area and I am not sure what the other two pieces are for, but they are made out of the same material as the stand. The way it is adjusted is by the rectangle piece with a steel ball that fits into the aluminum bar and is adjustable to get the stand pushed flush with the tank. I have not installed it yet, but will update my build thread when I do.

Just figured I would post this for people still waiting and wondering what the kit will include.

I got on the list ,I think the 2nd day it was out no word of my brace yet.

guessing it will come in the next week or so...

guessing it will come in the next week or so...

U

User1

Guest

View BadgesI think they will. Imagine the damage coming from the negative publicity of Red Sea tanks exploding left and right.

This is a good point and one I'm sure they finally received. Take Marineland for example. The drama over their 300 DD series blowing out seams and the negative publicity. It was a tank I put a deposit on. Saw one, then two thread on different boards and asked for my deposit back. Granted we don't know how many owners didn't have problems (probably more than did) but the fact issues with a large aquarium happened and the delay in addressing publics concern...well...it lingers.

Marineland was the first on my list of not buying. Now Red Sea is added (and I'm a Red Sea fan). Doesn't matter if they fix it or not after the fact it isn't coming in my home. Water causes damage to homes and saltwater is warp factor 10. No tanks

I am glad they are trying and hope for the best to all the reefers with them.

Got my kit and installed it today. It took about 30-45 minutes. Install is quite simple. The instructions are just pictorial without any written explanations. I would like to make some comments particularly as it concern mounting and judging the pressure to apply with the jack.

Once you unscrew the existing door plastic pushers, screw in the supplied small wooden plate with the jack, I suggest using a level to make sure the support bar perfectly perpendicular, however I do not know if this is necessary. Eyeballing it may be just enough.

Then slowly crank up the jack by turning the screw clockwise. I believe this is the key portion of this install. You don't want to crank the jack too high or too low. The goal is to have as even pressure as possible supporting the bottom of the tank.

This is how I did it as it made sense to me, dont take it as gospel but I think it is a little more accurate than just matching heights as in the instructions:

First I cranked up the screw jack to have the center support at the same height as I measured at the side corner as per instructions. This coincided to an increase in the resistance I felt turning the screw. At this point I checked the thickness of the foam under the tank and I noticed it was more compressed toward the left side corner (i.e lesser thickness) than it was in the middle. This suggested that even if the gap between the bottom of the tank and the foam above the stand was closed the tank may still not be evenly supported as there was more pressure on the side than it was at the level of the jack. So I decided to crank it up a little more until the foam was just slightly more compressed at the level of the support brace. In other words I went deliberately slightly overboard with the jack height until the foam was slightly more compressed at the level of the support brace. This is obviously to much pressure so I dialed back, carefully observing the foam thickness until the indentation on the foam disappeared and the foam thickness was even. I did this maneuvering because I did not feel that the foam merely touching the bottom of the tank would mean equal pressure as the corners. I felt that by going a little higher and creating a little more pressure seen as a lesser thickness of the foam, then dialing back until the foam thickness was even would create a more even pressure distribution than just having the foam barely touching the bottom.

The remaining part of the install was trivial. there are two boards that need to be screwed under the tank at the side walls, few rubber covers to place and new door pushers to be installed. Overall an easy fix.

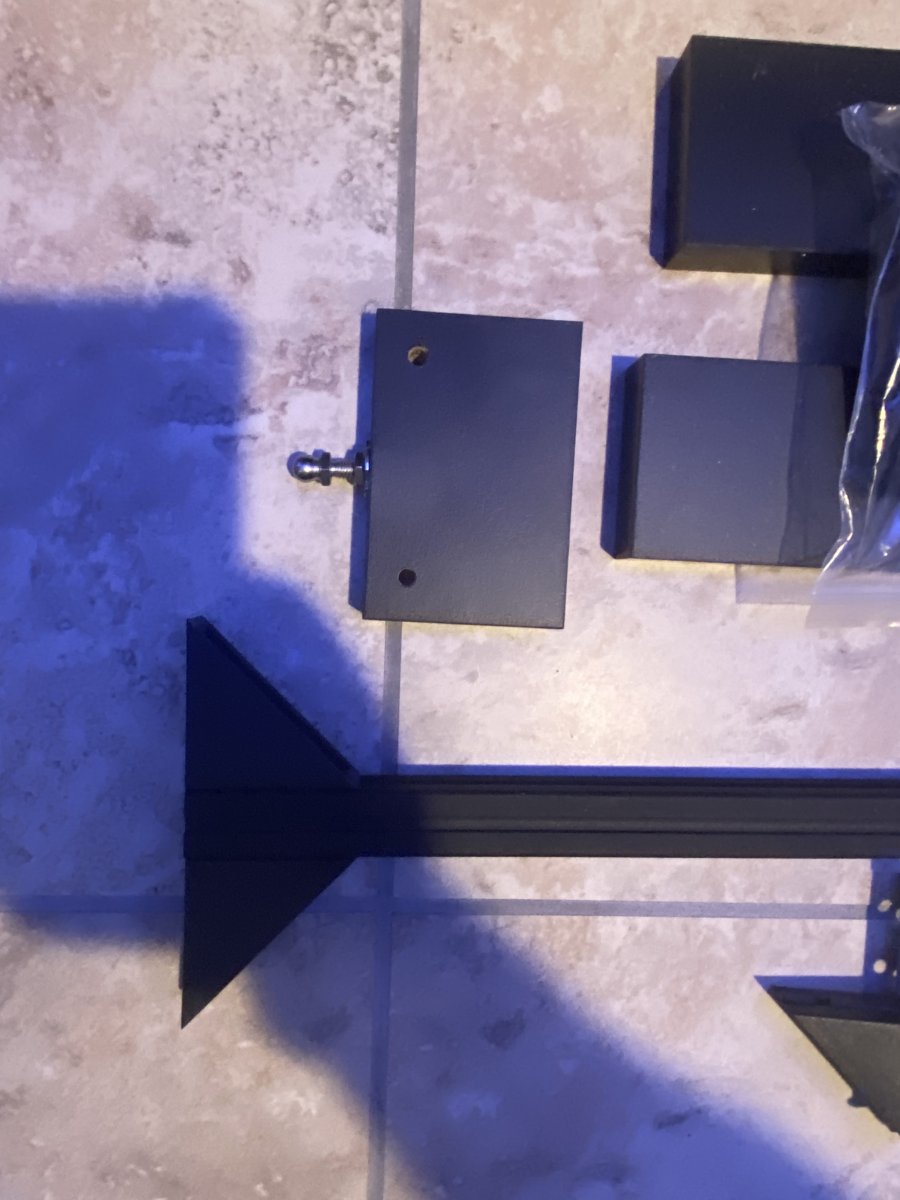

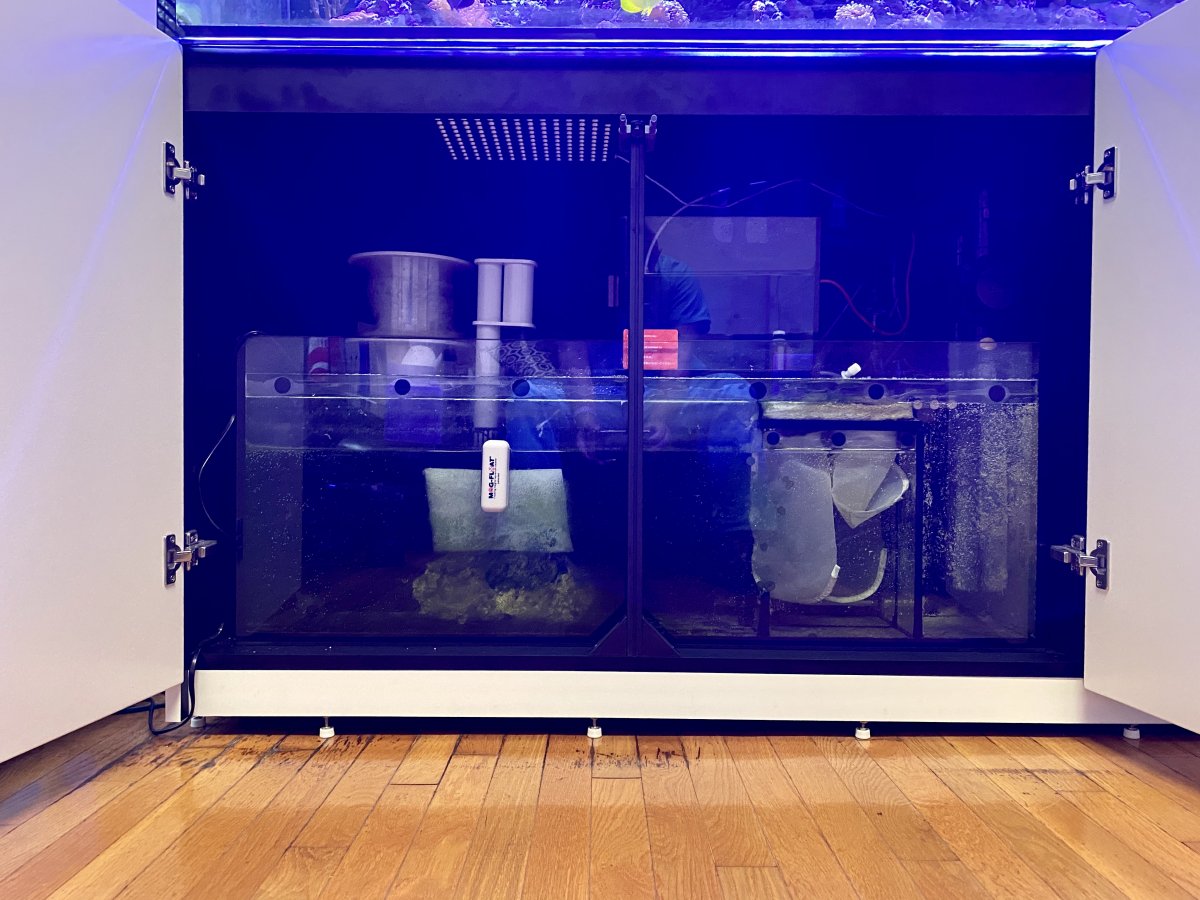

Here it is when done.

Once you unscrew the existing door plastic pushers, screw in the supplied small wooden plate with the jack, I suggest using a level to make sure the support bar perfectly perpendicular, however I do not know if this is necessary. Eyeballing it may be just enough.

Then slowly crank up the jack by turning the screw clockwise. I believe this is the key portion of this install. You don't want to crank the jack too high or too low. The goal is to have as even pressure as possible supporting the bottom of the tank.

This is how I did it as it made sense to me, dont take it as gospel but I think it is a little more accurate than just matching heights as in the instructions:

First I cranked up the screw jack to have the center support at the same height as I measured at the side corner as per instructions. This coincided to an increase in the resistance I felt turning the screw. At this point I checked the thickness of the foam under the tank and I noticed it was more compressed toward the left side corner (i.e lesser thickness) than it was in the middle. This suggested that even if the gap between the bottom of the tank and the foam above the stand was closed the tank may still not be evenly supported as there was more pressure on the side than it was at the level of the jack. So I decided to crank it up a little more until the foam was just slightly more compressed at the level of the support brace. In other words I went deliberately slightly overboard with the jack height until the foam was slightly more compressed at the level of the support brace. This is obviously to much pressure so I dialed back, carefully observing the foam thickness until the indentation on the foam disappeared and the foam thickness was even. I did this maneuvering because I did not feel that the foam merely touching the bottom of the tank would mean equal pressure as the corners. I felt that by going a little higher and creating a little more pressure seen as a lesser thickness of the foam, then dialing back until the foam thickness was even would create a more even pressure distribution than just having the foam barely touching the bottom.

The remaining part of the install was trivial. there are two boards that need to be screwed under the tank at the side walls, few rubber covers to place and new door pushers to be installed. Overall an easy fix.

Here it is when done.

U

User1

Guest

View BadgesGot my kit and installed it today. It took about 30-45 minutes. Install is quite simple. The instructions are just pictorial without any written explanations. I would like to make some comments particularly as it concern mounting and judging the pressure to apply with the jack.

Once you unscrew the existing door plastic pushers, screw in the supplied small wooden plate with the jack, I suggest using a level to make sure the support bar perfectly perpendicular, however I do not know if this is necessary. Eyeballing it may be just enough.

Then slowly crank up the jack by turning the screw clockwise. I believe this is the key portion of this install. You don't want to crank the jack too high or too low. The goal is to have as even pressure as possible supporting the bottom of the tank.

This is how I did it as it made sense to me, dont take it as gospel but I think it is a little more accurate than just matching heights as in the instructions:

First I cranked up the screw jack to have the center support at the same height as I measured at the side corner as per instructions. This coincided to an increase in the resistance I felt turning the screw. At this point I checked the thickness of the foam under the tank and I noticed it was more compressed toward the left side corner (i.e lesser thickness) than it was in the middle. This suggested that even if the gap between the bottom of the tank and the foam above the stand was closed the tank may still not be evenly supported as there was more pressure on the side than it was at the level of the jack. So I decided to crank it up a little more until the foam was just slightly more compressed at the level of the support brace. In other words I went deliberately slightly overboard with the jack height until the foam was slightly more compressed at the level of the support brace. This is obviously to much pressure so I dialed back, carefully observing the foam thickness until the indentation on the foam disappeared and the foam thickness was even. I did this maneuvering because I did not feel that the foam merely touching the bottom of the tank would mean equal pressure as the corners. I felt that by going a little higher and creating a little more pressure seen as a lesser thickness of the foam, then dialing back until the foam thickness was even would create a more even pressure distribution than just having the foam barely touching the bottom.

The remaining part of the install was trivial. there are two boards that need to be screwed under the tank at the side walls, few rubber covers to place and new door pushers to be installed. Overall an easy fix.

Here it is when done.

I do not own one of the tanks but as a fellow hobbyist just wanted to say thanks for taking the time to write this out and provide your experience. I'm sure it will help many out.

Question based on my reading through your post. Do you think there is room for error such that someone not being careful, or fully understanding what they are doing, could cause additional stress and/or bigger trouble?

Not a trick question but something that crossed my mind as you described the key point. Maybe go back and bold that

I do not own one of the tanks but as a fellow hobbyist just wanted to say thanks for taking the time to write this out and provide your experience. I'm sure it will help many out.

Question based on my reading through your post. Do you think there is room for error such that someone not being careful, or fully understanding what they are doing, could cause additional stress and/or bigger trouble?

Not a trick question but something that crossed my mind as you described the key point. Maybe go back and bold thatIn any case thanks again.

Doing... without understanding what you are doing is always an unfortunate proposition!

While mounting this kit I just had the feeling that it could be possible to place either not enough pressure or too much. I believe there is a good bit of tolerance and margin for error built in the system. The margin for error is provided by the foam under the tank which should smooth and even out difference in pressure. I just felt that by correcting the bowing of the crossbeam to the point that the gap between the bottom of the tank and the stand is barely closed, was probably good enough but not ideal as the foam was clearly more compressed at the side indicating a higher pressure than the middle. I felt that by doing that way I explained you could provide better support for the bottom of the tank.

To give a visual representation:

|

| Just too much pressure here

V

---------------------------

^.

|. Range of tolerance provided by the foam

|

| --------------- Perfect pressure here

|

V

---------------------------

^.

|. Just enough pressure here

|

I believe that there is a range of acceptable pressure, however there is more tolerance at the top of the picture (i.e. too much pressure side) as the foam can compress and compensate within reasonable limit for the additional pressure, however at the bottom of the picture (i.e. not enough pressure) the foam can not expand more than its nominal thickness to compensate for not enough pressure.Having said all this, probably I am overthinking this stuff. It may be sufficient that after reaching the point where the heights are matched and you start feeling an increase in resistance, just add 1/2 turn to the screw and be done.

I am one of those that would have probably gotten this wrong. I am an IT Consultant, not a cabinet builder and while I understand technical business needs, complex network design, configuration and installation, most computer systems and software development, I cannot seem to grasp putting furniture together. That is why I paid mt LFS to install my stand and tank initially and was dreading installing this new piece myself.Doing... without understanding what you are doing is always an unfortunate proposition!

While mounting this kit I just had the feeling that it could be possible to place either not enough pressure or too much. I believe there is a good bit of tolerance and margin for error built in the system. The margin for error is provided by the foam under the tank which should smooth and even out difference in pressure. I just felt that by correcting the bowing of the crossbeam to the point that the gap between the bottom of the tank and the stand is barely closed, was probably good enough but not ideal as the foam was clearly more compressed at the side indicating a higher pressure than the middle. I felt that by doing that way I explained you could provide better support for the bottom of the tank.

To give a visual representation:

|| Just too much pressure hereV---------------------------^.|. Range of tolerance provided by the foam|| --------------- Perfect pressure here|V---------------------------^.|. Just enough pressure here|I believe that there is a range of acceptable pressure, however there is more tolerance at the top of the picture (i.e. too much pressure side) as the foam can compress and compensate within reasonable limit for the additional pressure, however at the bottom of the picture (i.e. not enough pressure) the foam can not expand more than its nominal thickness to compensate for not enough pressure.

Having said all this, probably I am overthinking this stuff. It may be sufficient that after reaching the point where the heights are matched and you start feeling an increase in resistance, just add 1/2 turn to the screw and be done.

I was desperately searching to see if anyone had posted a video of this install yet, but unfortunately is it too early and the people that would post a video probably have not gotten the kit yet. I realize the longer I wait the worse my odds of a failure get, so I am going to install this today or tomorrow. Thanks for your post, as the directions might as well be in Japanese to me.

I am one of those that would have probably gotten this wrong. I am an IT Consultant, not a cabinet builder and while I understand technical business needs, complex network design, configuration and installation, most computer systems and software development, I cannot seem to grasp putting furniture together. That is why I paid mt LFS to install my stand and tank initially and was dreading installing this new piece myself.

I was desperately searching to see if anyone had posted a video of this install yet, but unfortunately is it too early and the people that would post a video probably have not gotten the kit yet. I realize the longer I wait the worse my odds of a failure get, so I am going to install this today or tomorrow. Thanks for your post, as the directions might as well be in Japanese to me.

If you have any questions just post here and will be glad to help.

- Joined

- Dec 12, 2018

- Messages

- 192

- Reaction score

- 201

Just read the entire thread and hoo boy what a ride. So happy for those with a ticking time bomb in their house to finally get a defuser!

It's hard for me to understand how customers will straight up embarrass themselves defending the honor of a company, shameful.

It's hard for me to understand how customers will straight up embarrass themselves defending the honor of a company, shameful.

My brace showed up today and here is what it consists of.

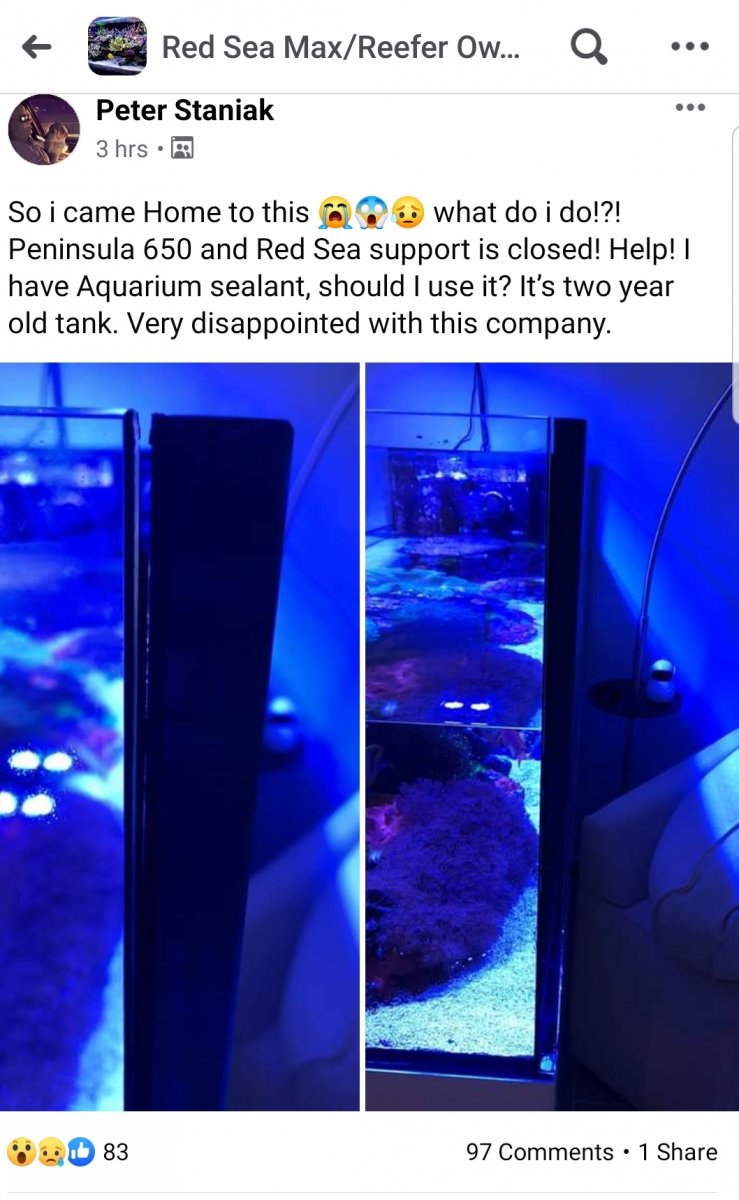

SO, there is another failure posted on the Red Sea Forum today and it is not a 750 XXL. Here is what was posted...

"So i came Home to this what do i do!?! Peninsula 650 and Red Sea support is closed! Help! I have Aquarium sealant, should I use it? It’s two year old tank. Very disappointed with this company."

Now I am scared all over again. This really sucks.

"So i came Home to this what do i do!?! Peninsula 650 and Red Sea support is closed! Help! I have Aquarium sealant, should I use it? It’s two year old tank. Very disappointed with this company."

Now I am scared all over again. This really sucks.

- Joined

- Oct 3, 2015

- Messages

- 5,165

- Reaction score

- 8,788

SO, there is another failure posted on the Red Sea Forum today and it is not a 750 XXL. Here is what was posted...

"So i came Home to this what do i do!?! Peninsula 650 and Red Sea support is closed! Help! I have Aquarium sealant, should I use it? It’s two year old tank. Very disappointed with this company."

Now I am scared all over again. This really sucks.

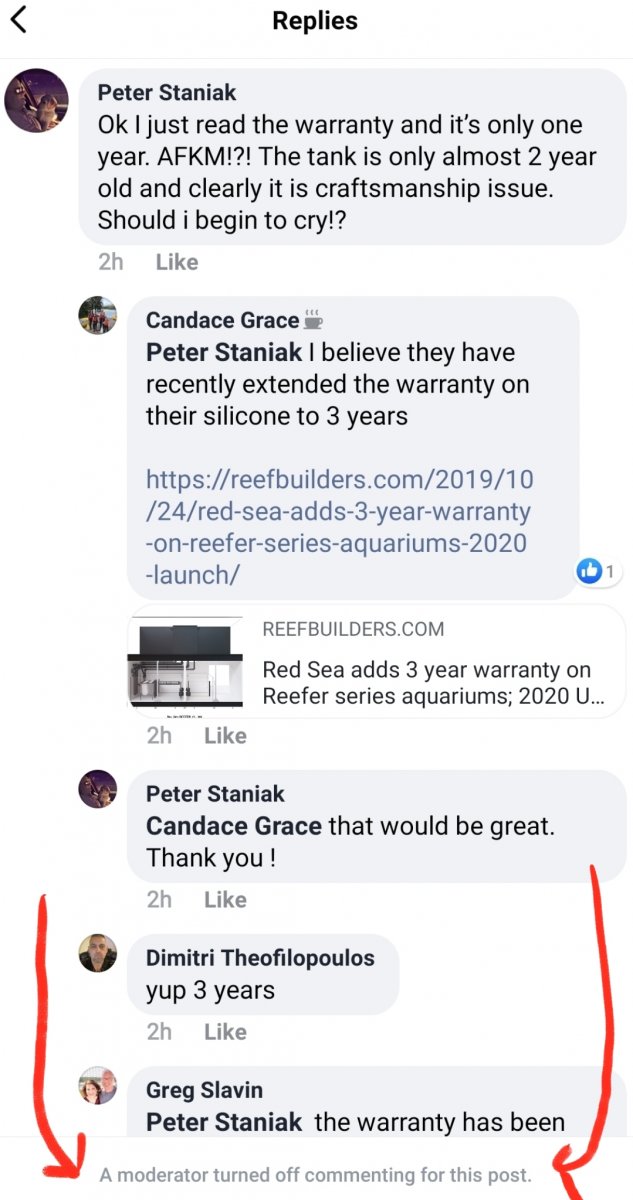

Is the post still up? Or did they delete it?

It's still up, but they shut down any comments.Is the post still up? Or did they delete it?

Edit: I just checked again and cannot find the post anymore...maybe they did delete it.

Last edited:

Baby steps...It's still up, but they shut down any comments.

My wife showed me the post just now. Crazy. I'm no longer apart of the group... lol. Commenting turned off by the moderators. At least it's not deleted... yet.

They have some quality issues for sure.

Time for Red Sea to come up with a sealant kit to send all their customers

They have some quality issues for sure.

Time for Red Sea to come up with a sealant kit to send all their customers

Last edited:

And this one was clearly not caused by a sagging stand. The seem clearly failed causing the back pane of glass to separate from the side. This is the third one that I have seen that I do not believe was caused by a stand design flaw. They all have not been 750 XXL's though. I guess they have more problems then they are admitting to.My wife showed me the post just now. Crazy. I'm no longer apart of the group... lol.

They have some quality issues for sure.

Added pictures to my post above.

With all these control issues.... what does Red Sea do? Release a bigger tank. Makes sense.

With all these control issues.... what does Red Sea do? Release a bigger tank. Makes sense.

Last edited:

Similar threads

- Replies

- 5

- Views

- 327

- Replies

- 215

- Views

- 8,573

- Replies

- 7

- Views

- 1,956

- Replies

- 5

- Views

- 164

TOP 10 Trending Threads

- Replies

- 54

- Views

- 859

- Replies

- 28

- Views

- 269

- Replies

- 22

- Views

- 379

- Replies

- 129

- Views

- 4,749

- Replies

- 66

- Views

- 1,004

- Replies

- 24

- Views

- 403