- Joined

- Mar 6, 2020

- Messages

- 75

- Reaction score

- 48

Welcome to my Build thread that will be following my new to me Planet Aquariums rimless 180 that is hopefully completed before I'm broke  . I'm hoping to stay on top of regular updates as I navigate the setup and overall maintenance of the system. First and foremost any and all advice, tips and general constructive criticism is very welcome here. A little about myself, I have been reefing for a year, but spend the better part of two years prior to my first setup obsessing about all things reef tank related. The 40 gal I currently have has been what I'd say fairly successful with of course a few hiccups along the way . So I'd consider myself a fairly novice reefer and am looking to learn more and more about this wonderful hobby. Along the way I somehow convinced my wife to a rather substantial upgrade lucky me lol. This system will be closed loop so plumbing may be a tad bit tricky for me lol, but overall I'm excited to take a crack at it and see how it goes. Aquascape I'm thinking about going for an NSA style.

. I'm hoping to stay on top of regular updates as I navigate the setup and overall maintenance of the system. First and foremost any and all advice, tips and general constructive criticism is very welcome here. A little about myself, I have been reefing for a year, but spend the better part of two years prior to my first setup obsessing about all things reef tank related. The 40 gal I currently have has been what I'd say fairly successful with of course a few hiccups along the way . So I'd consider myself a fairly novice reefer and am looking to learn more and more about this wonderful hobby. Along the way I somehow convinced my wife to a rather substantial upgrade lucky me lol. This system will be closed loop so plumbing may be a tad bit tricky for me lol, but overall I'm excited to take a crack at it and see how it goes. Aquascape I'm thinking about going for an NSA style.

Equipment:

lights- 2x Reefbreed photon 32-V2 pros (toying around with the idea of running them with a T5 hybrid fixture)

Closed loop pump- Dart/Snapper 3600/2600 pump

Closed loop wavemaker- Oceans Motions 4 way

Sump- Trigger ruby red 36

Return pump- WILL UPDATE

Skimmer- WILL UPDATE

Controllers- Apex along with a trident

Fuge light- Cheapo Coralife LED

(I'm sure I've missed something and will update the equipment list as I go through my stuff)

Plumbing:

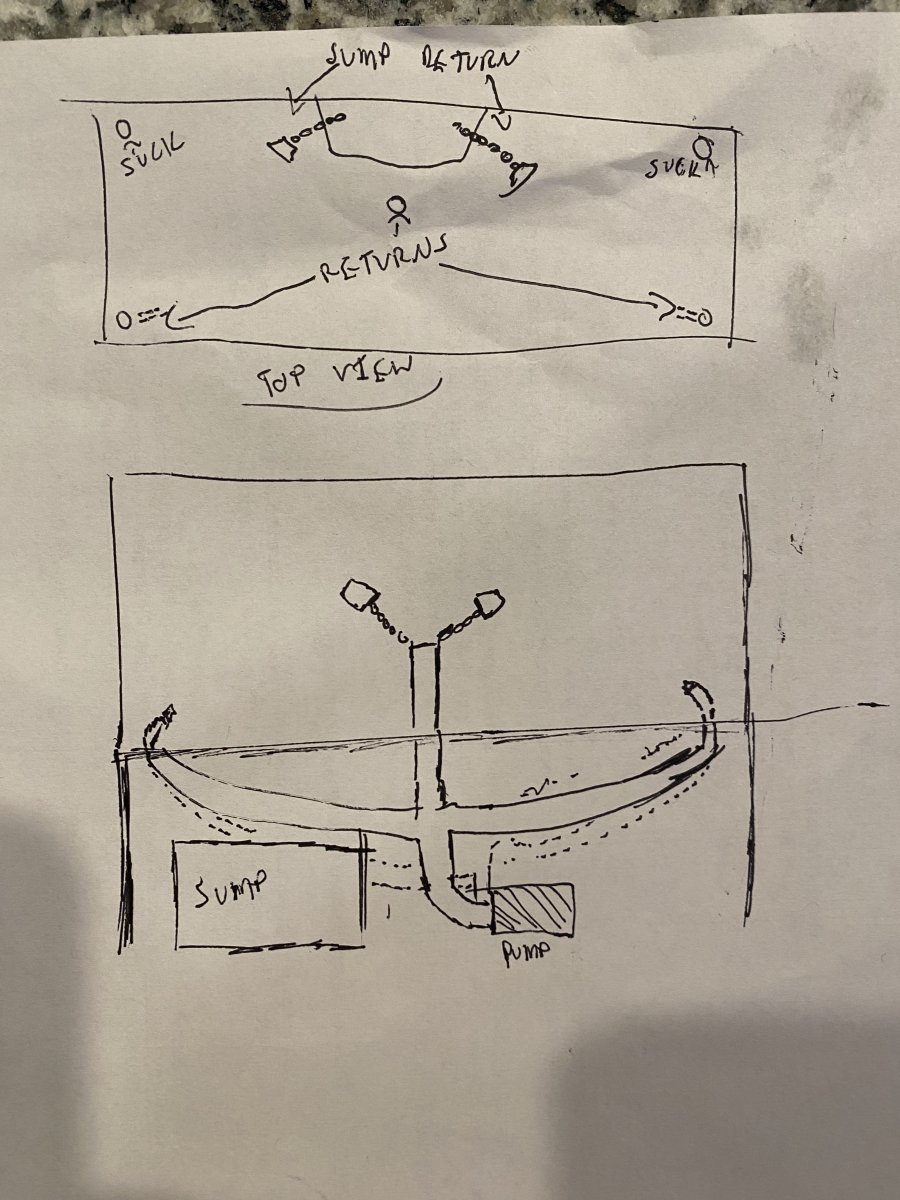

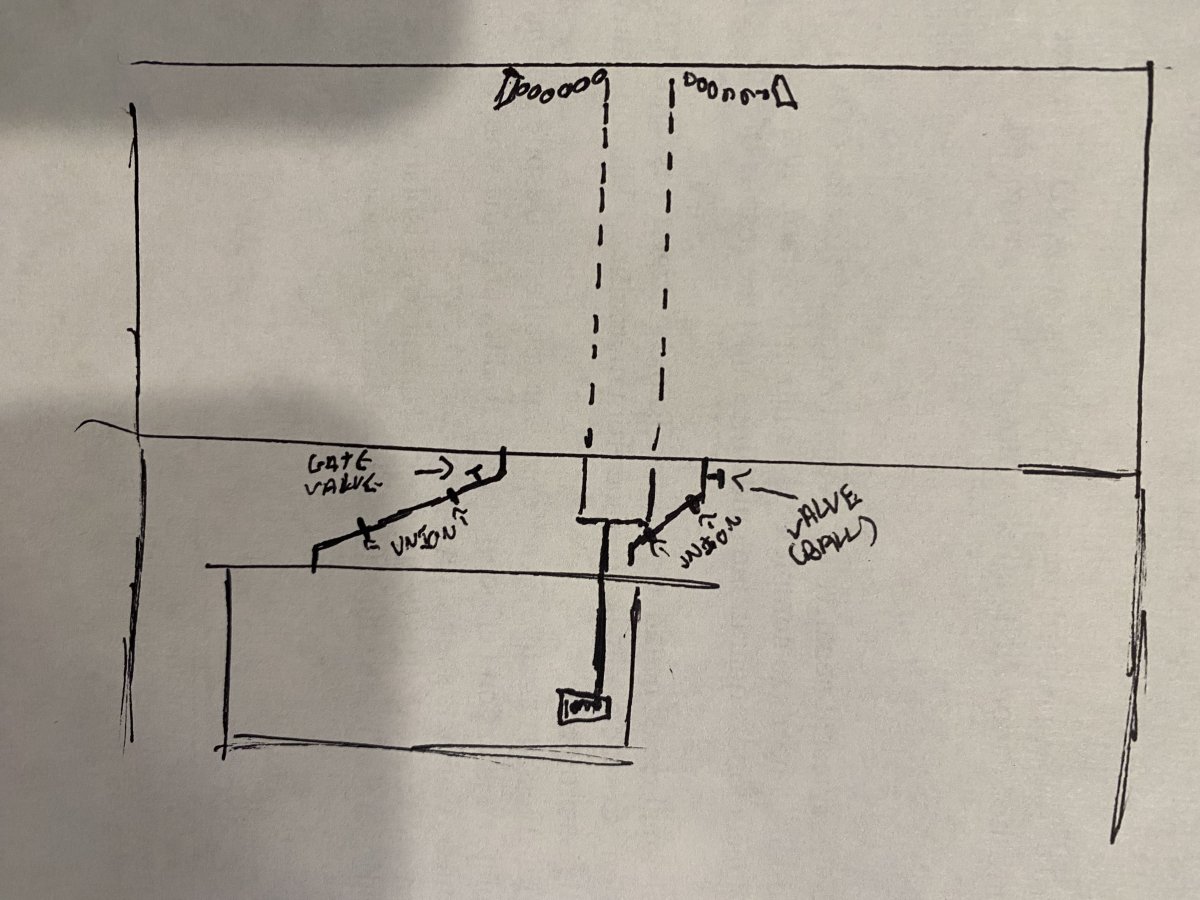

-The tank itself has 5 holes drilled for the closed loop and 4 holes drilled in the overflow all measuring 1' after bulkheads. See pictures for reference. Current plan is to run a Herbie method for sump overflow and return (overflow lines 1" and return lines 3/4"). I'm thinking the middle holes for overflow and the outer two for return.

-As for the closed loop I'm thinking about using the back two holes for the suction lines and the middle/fronts for return. The Middle with a T providing two nozzles to point left and right (I'm thinking roughly 6"-8" from the bottom of the tank) with the front two stubbing up with 45s angling it towards the overflow box. This is all in theory as I need to make sure I can either cap on of the 4 channels from the Oceans Motions or run 2 into 1. Any insight someone can give me on this would be greatly appreciated. See rough drawings for reference.

Livestock:

fish- I haven't done too much thinking about fish stocking other than what's in my 40gal currently and some tangs. More will be added to this after I conquer the plumbing and aquascape

Coral- will me mixed reef focused possibly more SPS dominant.

Looking forward to the journey and all the help I will likely receive along the way! I hope some of y'all join me!

Equipment:

lights- 2x Reefbreed photon 32-V2 pros (toying around with the idea of running them with a T5 hybrid fixture)

Closed loop pump- Dart/Snapper 3600/2600 pump

Closed loop wavemaker- Oceans Motions 4 way

Sump- Trigger ruby red 36

Return pump- WILL UPDATE

Skimmer- WILL UPDATE

Controllers- Apex along with a trident

Fuge light- Cheapo Coralife LED

(I'm sure I've missed something and will update the equipment list as I go through my stuff)

Plumbing:

-The tank itself has 5 holes drilled for the closed loop and 4 holes drilled in the overflow all measuring 1' after bulkheads. See pictures for reference. Current plan is to run a Herbie method for sump overflow and return (overflow lines 1" and return lines 3/4"). I'm thinking the middle holes for overflow and the outer two for return.

-As for the closed loop I'm thinking about using the back two holes for the suction lines and the middle/fronts for return. The Middle with a T providing two nozzles to point left and right (I'm thinking roughly 6"-8" from the bottom of the tank) with the front two stubbing up with 45s angling it towards the overflow box. This is all in theory as I need to make sure I can either cap on of the 4 channels from the Oceans Motions or run 2 into 1. Any insight someone can give me on this would be greatly appreciated. See rough drawings for reference.

Livestock:

fish- I haven't done too much thinking about fish stocking other than what's in my 40gal currently and some tangs. More will be added to this after I conquer the plumbing and aquascape

Coral- will me mixed reef focused possibly more SPS dominant.

Looking forward to the journey and all the help I will likely receive along the way! I hope some of y'all join me!