Hello,

I have two questions.

I've spent a lot of time reading over threads on aluminum stands, such as this one: https://www.reef2reef.com/threads/show-us-your-t-slot-aluminum-stands.302935/page-3

I reached out to a well known company that does them, and admit I am confused on their answer. I asked about the strength ratings of the fasteners used (how many lbs load rating, etc) with reference to the sump, not the main display tank.

The main display tank would have the load transferred to the vertical legs, but all the pictures I see show sumps sitting only on the horizontal cross-beams..... which are only held by the anchors horizontally.

When I asked for the direct load rating of these, I was told that the extrusion bars do most of the load bearing. I responded with a photo showing sumps sitting across the middle of the bottom cross beams and clarified.

I was told again, "It would still be the extrusion bearing most of the load with the connectors just securing the pieces in place."

Am I missing something here?

1 ) How do the extrusion cross beams on the bottom of the stand do most of the load bearing, when they essentially are floating in between the length-wise bars and only connected by the anchors on each side?

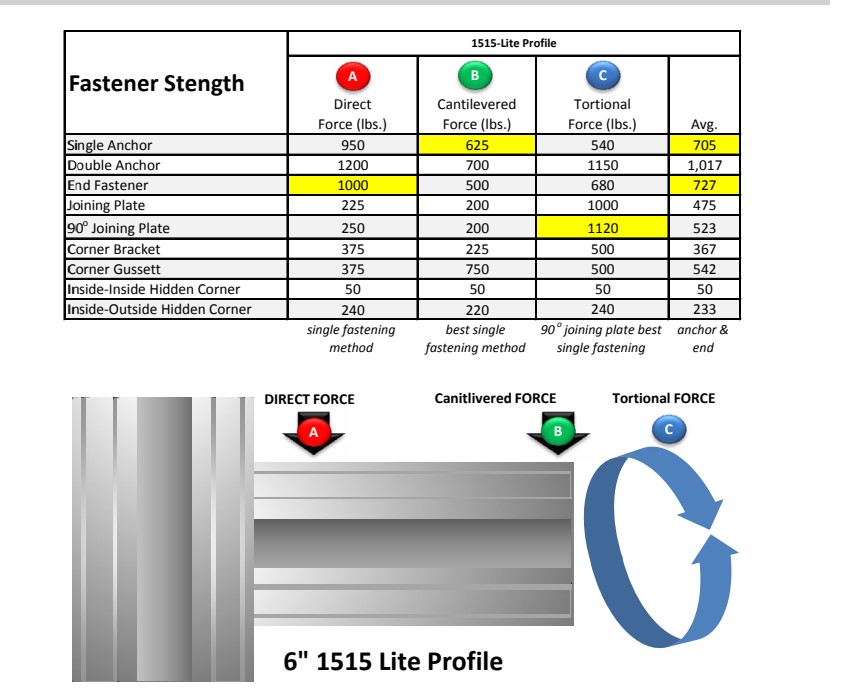

I then browsed around online and found references in catalogues of example strengths for a 6" 1515 profile:

Can anyone help me understand this? Not exact extrapolation, but if 6" is 700 on average, if the cross profile for the sump was say 36" wide on the bottom, could it be 705lb/6 = 117lb. So each anchor fastener on the bottom could be capable of holding around 100lbs for a 36" long bar? And with all the anchors in each bar across the bottom, it ends up being enough?

2) My second question is I read that stainless steel and aluminum should not be used together due to galvanic corrosion (similar to a boat and sacrificial anodes). I see one company uses stainless steel anchors with aluminum profiles. Others use zinc. Is this an issue or is that only for untreated/non-anodized aluminum?

I am new to aluminum stands, so go easy

I have two questions.

I've spent a lot of time reading over threads on aluminum stands, such as this one: https://www.reef2reef.com/threads/show-us-your-t-slot-aluminum-stands.302935/page-3

I reached out to a well known company that does them, and admit I am confused on their answer. I asked about the strength ratings of the fasteners used (how many lbs load rating, etc) with reference to the sump, not the main display tank.

The main display tank would have the load transferred to the vertical legs, but all the pictures I see show sumps sitting only on the horizontal cross-beams..... which are only held by the anchors horizontally.

When I asked for the direct load rating of these, I was told that the extrusion bars do most of the load bearing. I responded with a photo showing sumps sitting across the middle of the bottom cross beams and clarified.

I was told again, "It would still be the extrusion bearing most of the load with the connectors just securing the pieces in place."

Am I missing something here?

1 ) How do the extrusion cross beams on the bottom of the stand do most of the load bearing, when they essentially are floating in between the length-wise bars and only connected by the anchors on each side?

I then browsed around online and found references in catalogues of example strengths for a 6" 1515 profile:

Can anyone help me understand this? Not exact extrapolation, but if 6" is 700 on average, if the cross profile for the sump was say 36" wide on the bottom, could it be 705lb/6 = 117lb. So each anchor fastener on the bottom could be capable of holding around 100lbs for a 36" long bar? And with all the anchors in each bar across the bottom, it ends up being enough?

2) My second question is I read that stainless steel and aluminum should not be used together due to galvanic corrosion (similar to a boat and sacrificial anodes). I see one company uses stainless steel anchors with aluminum profiles. Others use zinc. Is this an issue or is that only for untreated/non-anodized aluminum?

I am new to aluminum stands, so go easy