Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Arduino powered diy sea sweep! Oscillating wavemaker diy!

- Thread starter mstockmaster

- Start date

- Tagged users None

Sorry I haven't been on here in forever. Having a baby along with other hobbies and projects have kinda pushed the tank to the back burner. Plus my t5 fell in the tank a few months ago causing a slow crash. So I'm about to tear it down and start fresh. But, to answer the question, yes the servo is still running. You can definitely tell that it's wearing out because its no longer a smooth sweep all the time, there are some dead spots for sure. But it's been running 24/7 for the past 977 days straight with no real issues, assuming a sweep takes 15 seconds that's over 5.5 million sweeps, which I'd say is pretty great. I honestly didn't think the servo would last a year.Any updates on how well the servo's are performing? I search the web and found some Heavy Duty/waterproof; would they work?

Congratulations!!!

I did some research and found another board that can be used for this purpose and build my own. So far they been running close to a year but depending on pump speed they can be a little noisy. One of the servos bottom shaft is faulty (not the same as listed here). I’m in the process of replacing them but this time I’m going to place them with gear down.

I did some research and found another board that can be used for this purpose and build my own. So far they been running close to a year but depending on pump speed they can be a little noisy. One of the servos bottom shaft is faulty (not the same as listed here). I’m in the process of replacing them but this time I’m going to place them with gear down.

- Joined

- Jan 31, 2019

- Messages

- 369

- Reaction score

- 166

You've inspired me - I have an UNO lying around. I also have one of these brackets I bought years ago (was building something similar using PICAXE - but never finished it.

I also have a bracket I bought online that is purpose built for DIY sea sweeps and takes the Futaba servo's - https://neo3plus.com/en/accessoires/203-osmolateur-digiosmo.html

I also have a bracket I bought online that is purpose built for DIY sea sweeps and takes the Futaba servo's - https://neo3plus.com/en/accessoires/203-osmolateur-digiosmo.html

Last edited:

What board did you use?Congratulations!!!

I did some research and found another board that can be used for this purpose and build my own. So far they been running close to a year but depending on pump speed they can be a little noisy. One of the servos bottom shaft is faulty (not the same as listed here). I’m in the process of replacing them but this time I’m going to place them with gear down.

Nope. Just Amazon availabilityAny details on why you have selected this specific servo? What makes this one special over others?

Thanks!

I ordered the below servo - the waterproof sold me. Will it work?

ANNIMOS 20KG RC Servo Digital High Torque Full Metal Gear Waterproof,180° Control Angle

The ones I ordered are dual shaft and come with brackets,FYI

I also have a bracket I bought online that is purpose built for DIY sea sweeps and takes the Futaba servo's - https://neo3plus.com/en/accessoires/203-osmolateur-digiosmo.html

Is this sold by anyone in the US?

- Joined

- Jan 31, 2019

- Messages

- 369

- Reaction score

- 166

I'm actually in Australia, but just bought in online.Is this sold by anyone in the US?

Anyway I found an old Ardunio lying around and made a prototype. So far I have a setup routine that allows you to use encoder to set left and right swing points and a routine to manually "point" the servo with the encoder. Just need to write the routine to "swing" the pump and connect a 3 way switch.

- Joined

- Jan 31, 2019

- Messages

- 369

- Reaction score

- 166

This is my first go at Arduino so hopefully some pro's can help fix my code (seems to be working but I am sure it's far from best practice).

I've also reused bits of code from all over the internet, but found this guys Youtube channel great - https://www.youtube.com/channel/UC8z5SHQhi9veBOAaFPZffNA (a lot of my code started from his)

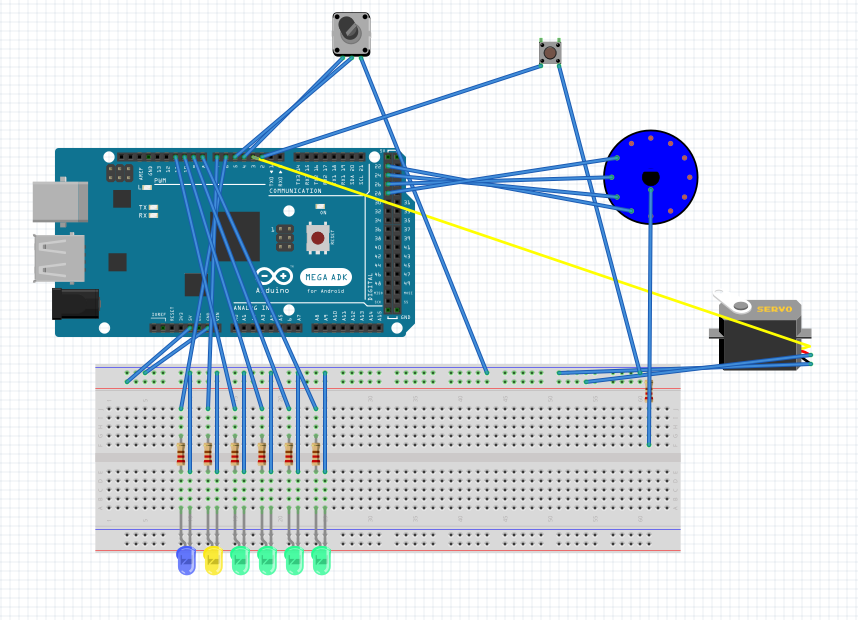

Any, as a description. I have a rotary encoder with push button (represented in the Fritz as 2 separate components), a 1 pole, 12 way rotary switch (set to 4 positions only), a servo (Futuba as it fits the bracket I have and is cheap to replace if it doesn't last) and some LED's (blue/white which work with encoder and 4 x green with indicate he position of the rotary switch).

Switch Position 1:

Use the rotary encoder to move the servo left/right. Push button stores the position and moves the servo to the other (ie. move it to left position, push button, left limit is stored and servo moves to right stored position. Move servo to right limit, push button and it stores the position and switches back to the left stored position).

Switch Position 2:

Servo moves according to rotary encoder. Push button does nothing.

Switch Position 3:

Servo sweeps from left position to right position to left position, to right position and so on. Pressing and holding the encoder button pauses the servo and allows you to speed up or slow down (adjust) the speed of the sweep.

Switch Position 4:

Saved for future. Thinking maybe uses the left and right positions, but uses a random sweep speed that changes every time. Open to other possibilities.

The Fritz diagram (once again my first go at it - I couldn't get it to look as neat as I wanted.)

The code

And forgive me for the crude video but here is a quick demo of it in action (the screeching of the servo is much worse in the video than in real life). First switch position was 1 (setting left and right limits), 2nd was "manually" pointing it, 3rd was a sweep from left -> right -> left (including adjusting the sweep speed - I think I need to reverse the up vs down direction for sweep speed) and 4th is just flashing lights at this stage.

Please feel free to suggest any improvements.

I've also reused bits of code from all over the internet, but found this guys Youtube channel great - https://www.youtube.com/channel/UC8z5SHQhi9veBOAaFPZffNA (a lot of my code started from his)

Any, as a description. I have a rotary encoder with push button (represented in the Fritz as 2 separate components), a 1 pole, 12 way rotary switch (set to 4 positions only), a servo (Futuba as it fits the bracket I have and is cheap to replace if it doesn't last) and some LED's (blue/white which work with encoder and 4 x green with indicate he position of the rotary switch).

Switch Position 1:

Use the rotary encoder to move the servo left/right. Push button stores the position and moves the servo to the other (ie. move it to left position, push button, left limit is stored and servo moves to right stored position. Move servo to right limit, push button and it stores the position and switches back to the left stored position).

Switch Position 2:

Servo moves according to rotary encoder. Push button does nothing.

Switch Position 3:

Servo sweeps from left position to right position to left position, to right position and so on. Pressing and holding the encoder button pauses the servo and allows you to speed up or slow down (adjust) the speed of the sweep.

Switch Position 4:

Saved for future. Thinking maybe uses the left and right positions, but uses a random sweep speed that changes every time. Open to other possibilities.

The Fritz diagram (once again my first go at it - I couldn't get it to look as neat as I wanted.)

The code

Code:

/* Need to do the following

* Need to store setpoint[1] & setpoint[2] and sweep_array[sweep_delay] values in EEPROM in case of power outage

* and read them back on boot

*/

#include <Servo.h>

//#include <EEPROM.h>

// define pins to be used

#define ENC_SW_PIN 2

#define SERVO_PIN 3

#define ENC_DATA_PIN 4

#define ENC_CLK_PIN 5

#define LEFT_LED 6

#define RIGHT_LED 7

#define LED_1 8

#define LED_2 9

#define LED_3 10

#define LED_4 11

#define SW_ROT1 22

#define SW_ROT2 24

#define SW_ROT3 26

#define SW_ROT4 28

//define variables

#define INCREMENT 1

#define SWEEP_INCREMENT 10

#define SERVO_INTERVAL 5 //ms between servo steps

#define MIN_ANGLE 5

#define MAX_ANGLE 175

#define MIN_SWEEP 50

#define MAX_SWEEP 500

byte sweep_delay;

byte enc_clk, enc_clk_old;

byte enc_switch, enc_switch_old;

byte pointer; // pointer to setpoint[pointer]

int angle = (MIN_ANGLE + MAX_ANGLE) / 2;

int setpoint[2] = {angle, angle + 10}; //startup angles

int sweep_array[1] = {sweep_delay};

unsigned long timeforservo;

Servo servo;

void setup() {

pinMode (ENC_CLK_PIN,INPUT_PULLUP);

pinMode (ENC_DATA_PIN,INPUT_PULLUP);

pinMode (ENC_SW_PIN,INPUT_PULLUP);

pinMode (LEFT_LED, OUTPUT);

pinMode (RIGHT_LED, OUTPUT);

pinMode (SW_ROT1,INPUT_PULLUP);

pinMode (SW_ROT2,INPUT_PULLUP);

pinMode (SW_ROT3,INPUT_PULLUP);

pinMode (SW_ROT4,INPUT_PULLUP);

pinMode (LED_1,OUTPUT);

pinMode (LED_2,OUTPUT);

pinMode (LED_3,OUTPUT);

pinMode (LED_4,OUTPUT);

servo.attach(SERVO_PIN);

Serial.begin (9600);

enc_clk_old = digitalRead(ENC_CLK_PIN);

enc_switch_old = digitalRead(ENC_SW_PIN);

sweep_array[sweep_delay] = 50;

}

void loop() {

digitalRead (SW_ROT1);

digitalRead (SW_ROT2);

digitalRead (SW_ROT3);

digitalRead (SW_ROT4);

// THIS IS USED TO SET MIN AND MAX IN SETUP MODE

if (digitalRead (SW_ROT1) == 0) {

// Serial.println ("Setup Mode selected");

digitalRead (SW_ROT1);

digitalWrite (LED_1, HIGH);

digitalWrite (LED_2, LOW);

digitalWrite (LED_3, LOW);

digitalWrite (LED_4, LOW);

enc_switch = digitalRead(ENC_SW_PIN);

if((enc_switch == 0) && (enc_switch_old == 1)) { // 1->0 transition detected

pointer = (pointer + 1) % 2; // change servo setpoint

Serial.print("SETPOINT is ");

Serial.print(angle);

Serial.print(", Min Angle is currently ");

Serial.print(setpoint[0]);

Serial.print(", Max Angle is currently ");

Serial.println(setpoint[1]);

delay(50);

if (angle < setpoint[pointer]) {

digitalWrite (LEFT_LED, HIGH);

digitalWrite (RIGHT_LED, LOW);

} else {

digitalWrite (LEFT_LED, LOW);

digitalWrite (RIGHT_LED, HIGH);

}

}

enc_switch_old = enc_switch;

// READ ROTARY AND MODIFY SERVO SETPOINT MIN, MAX

enc_clk = digitalRead(ENC_CLK_PIN);

if((enc_clk == 1) && (enc_clk_old == 0)) { // 0->1 transition

if(digitalRead(ENC_DATA_PIN) == 1) {

setpoint[pointer] = setpoint[pointer] + INCREMENT;

} else {

setpoint[pointer] = setpoint[pointer] - INCREMENT;

}

if((setpoint[pointer] > MAX_ANGLE) && (angle > setpoint [0])) setpoint[pointer] = MAX_ANGLE;

if(setpoint[pointer] < MIN_ANGLE) setpoint[pointer] = MIN_ANGLE;

Serial.println(angle);

delay(10);

}

enc_clk_old = enc_clk;

// ROTATE SERVO

if (millis() > timeforservo) {

timeforservo = millis() + SERVO_INTERVAL;

if (angle < setpoint[pointer]) {

angle++;

}

if (angle > setpoint[pointer]) {

angle--;

}

servo.write(angle);

}

}

// THIS IS USED TO MOVE SERVO MANUALLY

if (digitalRead (SW_ROT2) ==0) {

digitalRead (SW_ROT2);

digitalWrite (LED_1, LOW);

digitalWrite (LED_2, HIGH);

digitalWrite (LED_3, LOW);

digitalWrite (LED_4, LOW);

// READ ROTARY AND MODIFY SERVO SETPOINT MIN, MAX

enc_clk = digitalRead(ENC_CLK_PIN);

if((enc_clk == 1) && (enc_clk_old == 0)) { // 0->1 transition

if(digitalRead(ENC_DATA_PIN) == 1) {

setpoint[pointer] = setpoint[pointer] + INCREMENT;

digitalWrite (LEFT_LED, LOW);

digitalWrite (RIGHT_LED, HIGH);

}

else {

setpoint[pointer] = setpoint[pointer] - INCREMENT;

digitalWrite (LEFT_LED, HIGH);

digitalWrite (RIGHT_LED, LOW);

}

if(setpoint[pointer] > MAX_ANGLE) setpoint[pointer] = MAX_ANGLE;

if(setpoint[pointer] < MIN_ANGLE) setpoint[pointer] = MIN_ANGLE;

Serial.println(setpoint[pointer]);

delay(10);

}

enc_clk_old = enc_clk;

// ROTATE SERVO

if (millis() > timeforservo) {

timeforservo = millis() + SERVO_INTERVAL;

if (angle < setpoint[pointer]) angle++;

if (angle > setpoint[pointer]) angle--;

servo.write(angle);

}

}

// THIS IS USED TO SWEEP FROM LEFT TO RIGHT AND BACK

if (digitalRead (SW_ROT3) == 0) {

// THIS CODE BELOW IS USED TO SWEEP

digitalWrite (LED_1, LOW);

digitalWrite (LED_2, LOW);

digitalWrite (LED_3, HIGH);

digitalWrite (LED_4, LOW);

Serial.println ("Sweep Mode selected");

Serial.print ("Encoder Switch pin is ");

Serial.println (digitalRead (ENC_SW_PIN));

Serial.print ("Sweep Speed is ");

Serial.println (sweep_array[sweep_delay]);

if (digitalRead (ENC_SW_PIN) == HIGH) {

for (angle = setpoint[0]; angle <= setpoint[1]; angle += 1) { // goes from MIN_ANGLE to MAX_ANGLE in increments of 1 degree

// for (angle = MIN_ANGLE; angle <= MAX_ANGLE; angle += 1) { // goes from MIN_ANGLE to MAX_ANGLE in increments of 1 degree

// LED's configured for left sweep

digitalWrite (LEFT_LED, HIGH);

digitalWrite (RIGHT_LED, LOW);

servo.write(angle); // tell servo to go to position 'angle'

delay(sweep_array[sweep_delay]); // waits for servo delay

digitalRead (SW_ROT3);

digitalRead (ENC_SW_PIN); // Reads encoder switch pin looking for press

while (digitalRead (ENC_SW_PIN) == LOW) {

// LED's both on to indicate speed configuration

digitalWrite (LEFT_LED, HIGH);

digitalWrite (RIGHT_LED, HIGH);

enc_clk = digitalRead(ENC_CLK_PIN);

if((enc_clk == 1) && (enc_clk_old == 0)) { // 0->1 transition

if(digitalRead(ENC_DATA_PIN) == 1) sweep_array[sweep_delay] = sweep_array[sweep_delay] + SWEEP_INCREMENT;

else sweep_array[sweep_delay] = sweep_array[sweep_delay] - SWEEP_INCREMENT;

if(sweep_array[sweep_delay] > MAX_SWEEP) sweep_array[sweep_delay] = MAX_SWEEP;

if(sweep_array[sweep_delay] < MIN_SWEEP) sweep_array[sweep_delay] = MIN_SWEEP;

Serial.print ("Sweep Delay is ");

Serial.println(sweep_array[sweep_delay]);

delay(10);

}

enc_clk_old = enc_clk;

}

}

Serial.println ("Finished MIN to MAX angle sweep");

for (angle = setpoint[1]; angle >= setpoint[0]; angle -= 1) { // goes from 180 degrees to 0 degrees

// for (angle = MAX_ANGLE; angle >= MIN_ANGLE; angle -= 1) { // goes from 180 degrees to 0 degrees

// LED's configured for right sweep

digitalWrite (LEFT_LED, LOW);

digitalWrite (RIGHT_LED, HIGH);

servo.write(angle); // tell servo to go to position in variable 'point of sale'

delay(sweep_array[sweep_delay]); // waits 15ms for the servo to reach the position

digitalRead (ENC_SW_PIN);

while (digitalRead (ENC_SW_PIN) == LOW) {

// LED's both on to indicate speed configuration

digitalWrite (LEFT_LED, HIGH);

digitalWrite (RIGHT_LED, HIGH);

enc_clk = digitalRead(ENC_CLK_PIN);

if((enc_clk == 1) && (enc_clk_old == 0)) { // 0->1 transition

if(digitalRead(ENC_DATA_PIN) == 1) sweep_array[sweep_delay] = sweep_array[sweep_delay] + SWEEP_INCREMENT;

else sweep_array[sweep_delay] = sweep_array[sweep_delay] - SWEEP_INCREMENT;

if(sweep_array[sweep_delay] > MAX_SWEEP) sweep_array[sweep_delay] = MAX_SWEEP;

if(sweep_array[sweep_delay] < MIN_SWEEP) sweep_array[sweep_delay] = MIN_SWEEP;

Serial.print ("Sweep Delay is ");

Serial.println(sweep_array[sweep_delay]);

delay(10);

}

enc_clk_old = enc_clk;

}

}

}

}

// THIS IS RESERVED - MAYBE FOR RANDOM SWEEP SPEED - CURRENTLY BLINKS LEDS

if (digitalRead (SW_ROT4) == LOW){

Serial.println ("Mode 4 selected");

digitalWrite (LED_1, LOW);

digitalWrite (LED_2, LOW);

digitalWrite (LED_3, LOW);

digitalWrite (LED_4, HIGH);

digitalWrite (LEFT_LED, LOW);

digitalWrite (RIGHT_LED, HIGH);

delay (100);

digitalWrite (LEFT_LED, HIGH);

digitalWrite (RIGHT_LED, LOW);

delay (100);

digitalRead (SW_ROT4);

}

}And forgive me for the crude video but here is a quick demo of it in action (the screeching of the servo is much worse in the video than in real life). First switch position was 1 (setting left and right limits), 2nd was "manually" pointing it, 3rd was a sweep from left -> right -> left (including adjusting the sweep speed - I think I need to reverse the up vs down direction for sweep speed) and 4th is just flashing lights at this stage.

Please feel free to suggest any improvements.

This thread has got me thinking I will do something similar but instead of a servo I would use a stepper motor and some linkage to control the sweep of a powerhead.

Aquatic Life made these few years ago at a very affordable price.

I just recently bought one, I have yet to put it on my tank.

I also do have the OG SeaSwirls on the bigger tank.

I just recently bought one, I have yet to put it on my tank.

I also do have the OG SeaSwirls on the bigger tank.

- Joined

- Jan 31, 2019

- Messages

- 369

- Reaction score

- 166

Aquatic Life made these few years ago at a very affordable price.

I just recently bought one, I have yet to put it on my tank.

I also do have the OG SeaSwirls on the bigger tank.

Not quite the same - the aquatic life one doesn't move an existing powerhead. I already have the Tunze 6105's in the tank (near a corner). I want to make it swirl.

Plus who doesn't like a bit of DIY.

For me the hardware is almost as much of a challange (enjoyment) as the tank itself.

- Joined

- Jan 31, 2019

- Messages

- 369

- Reaction score

- 166

I am thinking I will add another switch position and take a 1-10v input from a controller (I happen to use Profilux). That way I can set the 1-10v port up as a stream pump on wave mode. instead of ramping the pump up and down 0v will be left position, 10v will be right position.

Don't think it will add value - just something else to add. it's only really 2 resistors (so I can split the 10v into 0-5v and plug it into an ADC on the Arduino.

Don't think it will add value - just something else to add. it's only really 2 resistors (so I can split the 10v into 0-5v and plug it into an ADC on the Arduino.

Not quite the same - the aquatic life one doesn't move an existing powerhead. I already have the Tunze 6105's in the tank (near a corner). I want to make it swirl.

Plus who doesn't like a bit of DIY.

For me the hardware is almost as much of a challange (enjoyment) as the tank itself.

thats understandable. the price of the seasweeps are stupid crazy. Plus I have several older older tunzes i would like to put to use.

Similar threads

- Replies

- 1

- Views

- 240

- Price: $175

- Shipping Available

- Replies

- 3

- Views

- 637

- Replies

- 1

- Views

- 112