simple enough. I just need to more more diligent.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Eating Up RO Membranes

- Thread starter flyfisher2

- Start date

- Tagged users None

Indeed, hopefully that is all of your issue, bad news would be your buying another membrane cause you already killed your current one if this is the true root cause.simple enough. I just need to more more diligent.

I make 30 gallons at a time and no I don't open the bypass regularly. I make 30 gallons twice a week.Your making large amounts of water at once right? Not letting the unit turn on just to make like half a gallon and turn off, to then make just another half a gallon over and over?

When you do turn on to make water do you open the bypass (waste water outlet) and let it run full open for maybe 30 seconds before closing it off to start making your water?

the units are not exposed to the sun at all. they are under roof but outdoors so ambient temp is what would be the issue.The heat and UV rays will also degrade the plastic on your system, so another good reason to bring it inside as well.

I've got ball valves on mine so that initially it all goes down the brine waste line, then I open one valve and purge down the drain as RO until the TDS drops to my normal 3-5, then I close that valve and open the valve to send the water to my DI carts.When you do yours do you disconnect any hoses or just let all run as normal but all to waste water?

I should also mention prior to my RO I have ball valves and a T fitting. I purge the sediment and carbon a good 30 seconds down the drain then I close that valve and open up to send the water into the RO

Yep just ambient and water temp to worry about. I would imagine your ground water temp after stabilizing is in the 80s so it should be fine. Once the until heated water works through the flow would keep the system at a good operating temp, just have to get through that until startupthe units are not exposed to the sun at all. they are under roof but outdoors so ambient temp is what would be the issue.

post some pics when you can. I'd like to see if I can do something similar. I'd have to do something in the laundry room and have the Brute on wheels roll around because I don't have the space in there to leave a permanent install.I've got ball valves on mine so that initially it all goes down the brine waste line, then I open one valve and purge down the drain as RO until the TDS drops to my normal 3-5, then I close that valve and open the valve to send the water to my DI carts.

I should also mention prior to my RO I have ball valves and a T fitting. I purge the sediment and carbon a good 30 seconds down the drain then I close that valve and open up to send the water into the RO

so I may not need to bring the setup inside?Yep just ambient and water temp to worry about. I would imagine your ground water temp after stabilizing is in the 80s so it should be fine. Once the until heated water works through the flow would keep the system at a good operating temp, just have to get through that until startup

Do all your ball valves go to separate waste lines? If not they could be left open and recycled through your ro system. If that's all set it must be the warm temperatures causing the membranes to go bad prematurely.

edit - sorry that was @Woodyman that has all the ball valves. I'd guess the heat is causing the issues.

edit - sorry that was @Woodyman that has all the ball valves. I'd guess the heat is causing the issues.

You can Pop open one of those membranes and check for carbon dust or melted liner

so I may not need to bring the setup inside?

Maybe not, but it wouldn't cause any harm. Do you know how high the ambient temp reaches with where you have the unit stored? I know you said Florida, so I'm going to imagine based on the time of year you see anywhere from 70-100+

Do you happen to know your groundwater temp after purging your lines for ~2/3 minutes? Just curious how high your ground supply is coming out, but that's going to a seasonal change as well.

Once water fresh water starts flowing through the system you would have purged the hot stagnant water out and the fresh water would keep the system cool, however, the system is not always running, so its that hot stagnant water that could be causing you issues as it heats and sits on your membrane.

You can Pop open one of those membranes and check for carbon dust or melted liner

At this point it wouldn't hurt for you to cut one of the many that you've already gone through if you still have any of them, and if you do and can cut a cross section and post that would at least show us if is melting or got chewed up by carbon dust.

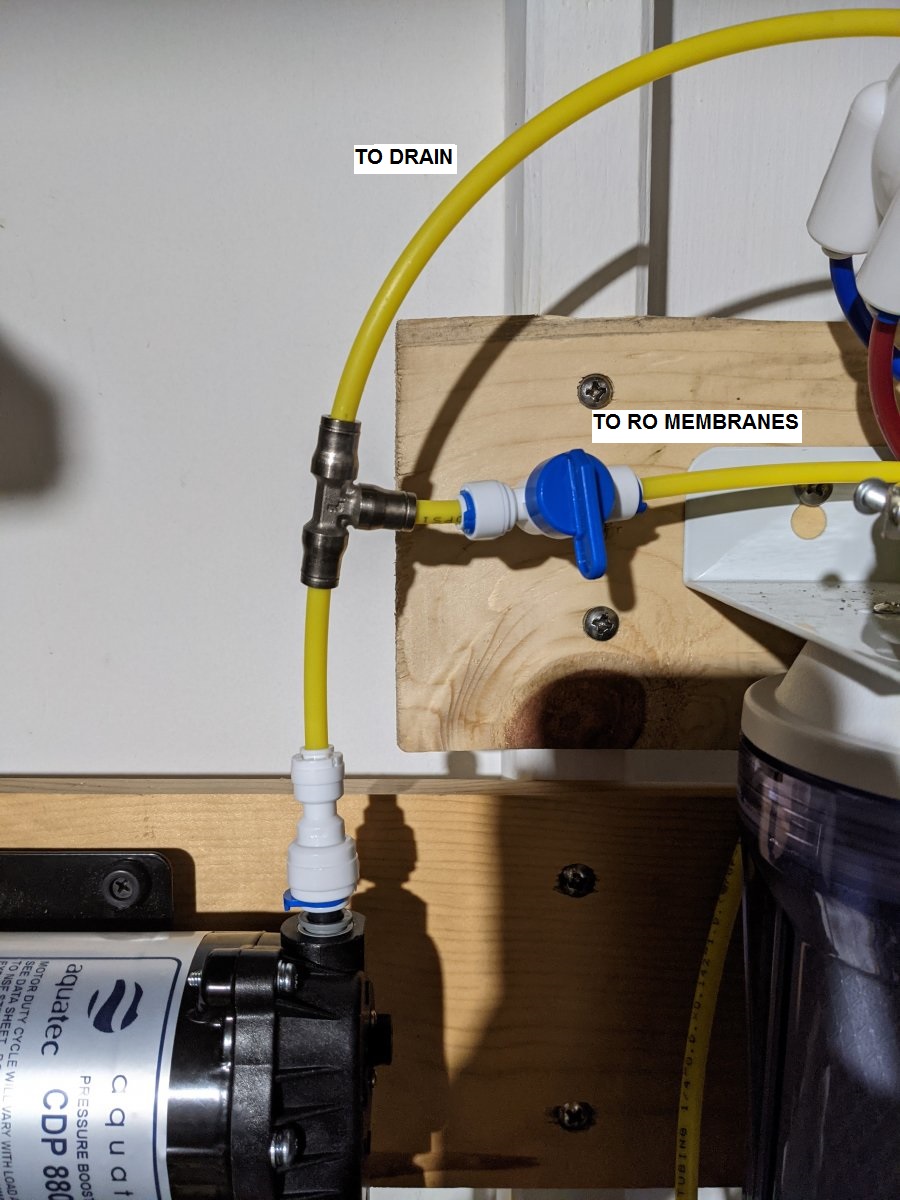

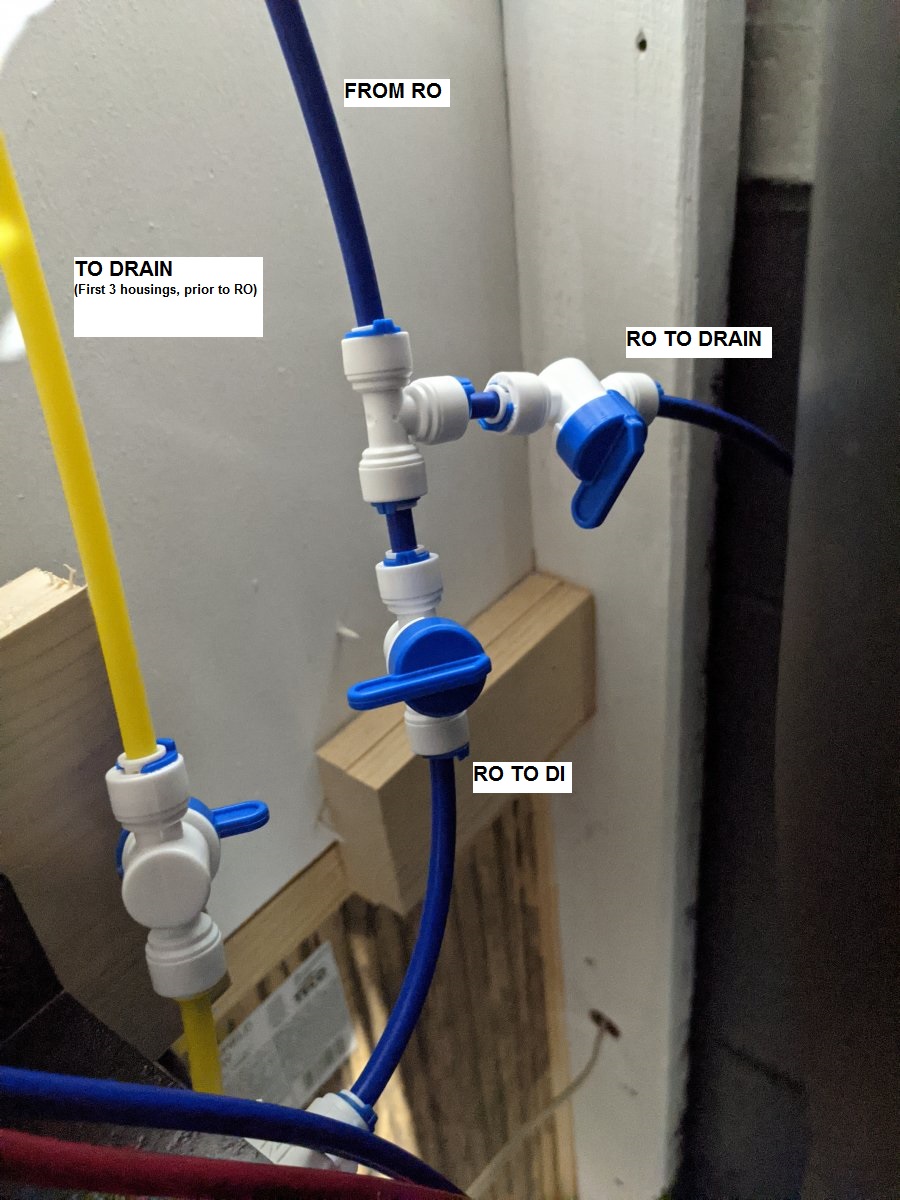

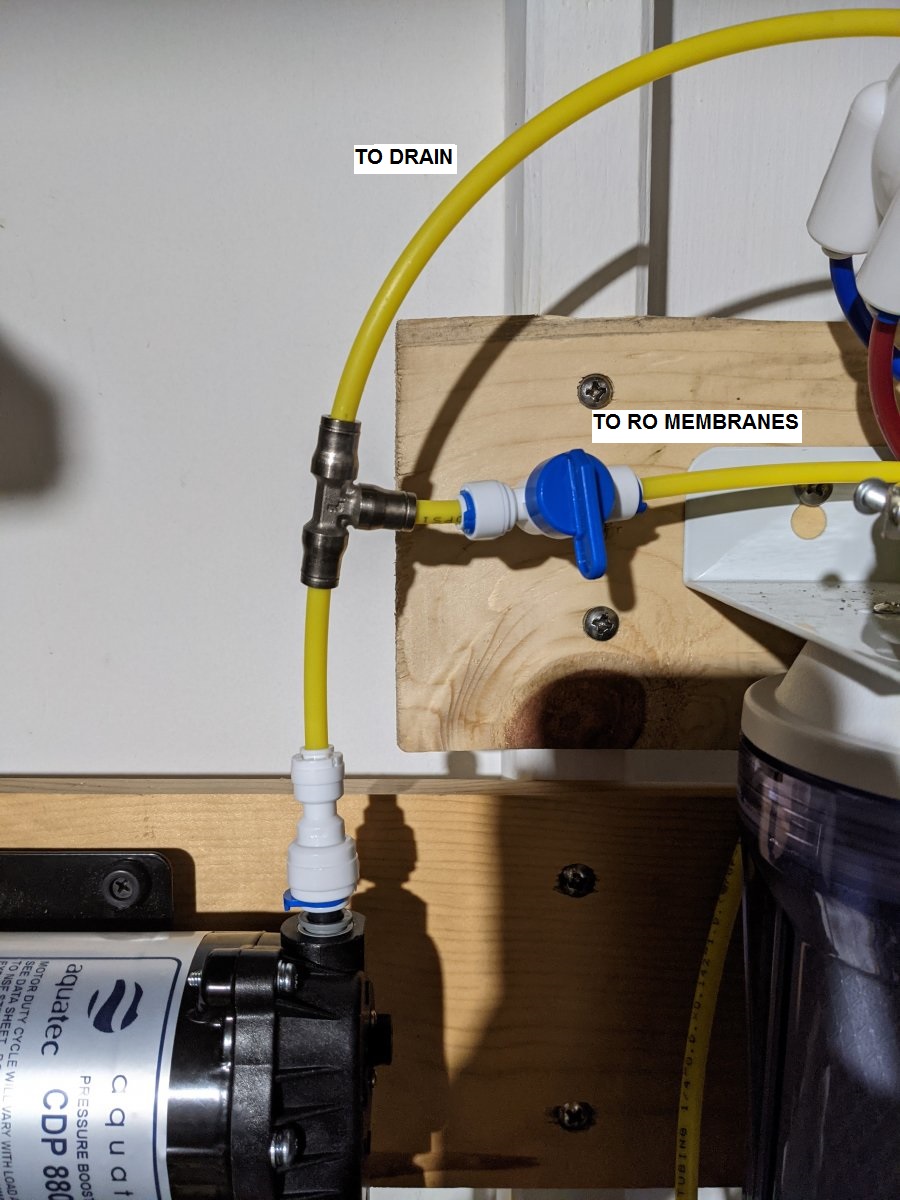

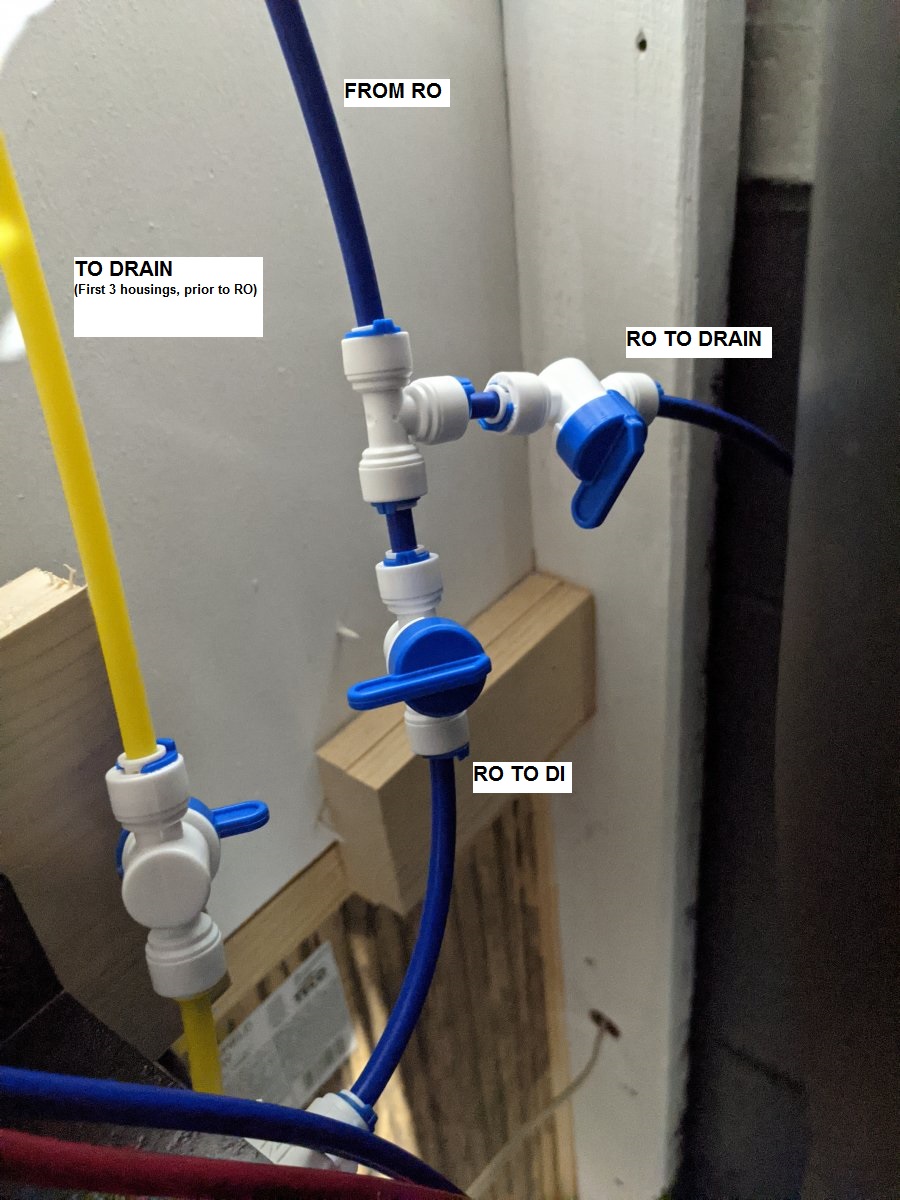

I recently moved my unit, so I still need to mount and clean up my hoses, but here is a picture of how I have my 'T' fittings, and ball valves setup to purge prior to sending to RO membrane, and again prior to sending to DI.

Above is a quick mockup I did with windows paint. I should put a nicer version together at some point, but it shows you the general flow, I run a sediment cartridge first, followed by 2 carbon filters, then to my RO. Prior to sending to RO I have the 'T' after the booster pump in the image above, the top of the 'T' you can see continuing in the image on the right, I have that going to drain when open, this way I purge the line for ~1 minute prior to turning it off and turning on the valve to the RO (right off the metal 'T' in image on the right).

I do the same thing post RO (image on the right). The bottom of the 'T' goes to my DI cartridges, and the right of the 'T' goes to the drain.

My process for starting up the system is as follows:

Purge incoming feed line for ~1 minute

Purge first 3 filter housings for ~1 minute

Turn off purge lines, and send water to RO membranes, at this time I have the 2 valves for RO closed, and send all water down the drain via the red brine drain with the flush full open.

I typically let it flush for ~1-3 minutes prior to opening the right of the 'T' to send RO to the drain

At this point I let it flush until my reading from the RO gets to between 3-6 TDS

Once I'm happy with the TDS I close the RO purge valve to the drain, and open the valve to send the RO water to my DI housings.

Above is a quick mockup I did with windows paint. I should put a nicer version together at some point, but it shows you the general flow, I run a sediment cartridge first, followed by 2 carbon filters, then to my RO. Prior to sending to RO I have the 'T' after the booster pump in the image above, the top of the 'T' you can see continuing in the image on the right, I have that going to drain when open, this way I purge the line for ~1 minute prior to turning it off and turning on the valve to the RO (right off the metal 'T' in image on the right).

I do the same thing post RO (image on the right). The bottom of the 'T' goes to my DI cartridges, and the right of the 'T' goes to the drain.

My process for starting up the system is as follows:

Purge incoming feed line for ~1 minute

Purge first 3 filter housings for ~1 minute

Turn off purge lines, and send water to RO membranes, at this time I have the 2 valves for RO closed, and send all water down the drain via the red brine drain with the flush full open.

I typically let it flush for ~1-3 minutes prior to opening the right of the 'T' to send RO to the drain

At this point I let it flush until my reading from the RO gets to between 3-6 TDS

Once I'm happy with the TDS I close the RO purge valve to the drain, and open the valve to send the RO water to my DI housings.

Last edited:

I just purged the membrane for 15 minutes. I disconnected the water line after the sediment and carbon blocks and prior to pressure gauge/membrane. Temp at that point is 81F. The TDS is 163PPM.Maybe not, but it wouldn't cause any harm. Do you know how high the ambient temp reaches with where you have the unit stored? I know you said Florida, so I'm going to imagine based on the time of year you see anywhere from 70-100+

Do you happen to know your groundwater temp after purging your lines for ~2/3 minutes? Just curious how high your ground supply is coming out, but that's going to a seasonal change as well.

Once water fresh water starts flowing through the system you would have purged the hot stagnant water out and the fresh water would keep the system cool, however, the system is not always running, so its that hot stagnant water that could be causing you issues as it heats and sits on your membrane.

At this point it wouldn't hurt for you to cut one of the many that you've already gone through if you still have any of them, and if you do and can cut a cross section and post that would at least show us if is melting or got chewed up by carbon dust.

As far as ambient temp in the area, It's 84 right now so afternoon definitely higher.

Last edited:

seeing the pics but not the mockup with windows paint. Getting a general idea. I'll show you mine in a few so you can see my situationI recently moved my unit, so I still need to mount and clean up my hoses, but here is a picture of how I have my 'T' fittings, and ball valves setup to purge prior to sending to RO membrane, and again prior to sending to DI.

Above is a quick mockup I did with windows paint. I should put a nicer version together at some point, but it shows you the general flow, I run a sediment cartridge first, followed by 2 carbon filters, then to my RO. Prior to sending to RO I have the 'T' after the booster pump in the image above, the top of the 'T' you can see continuing in the image on the right, I have that going to drain when open, this way I purge the line for ~1 minute prior to turning it off and turning on the valve to the RO (right off the metal 'T' in image on the right).

I do the same thing post RO (image on the right). The bottom of the 'T' goes to my DI cartridges, and the right of the 'T' goes to the drain.

My process for starting up the system is as follows:

Purge incoming feed line for ~1 minute

Purge first 3 filter housings for ~1 minute

Turn off purge lines, and send water to RO membranes, at this time I have the 2 valves for RO closed, and send all water down the drain via the red brine drain with the flush full open.

I typically let it flush for ~1-3 minutes prior to opening the right of the 'T' to send RO to the drain

At this point I let it flush until my reading from the RO gets to between 3-6 TDS

Once I'm happy with the TDS I close the RO purge valve to the drain, and open the valve to send the RO water to my DI housings.

Not bad as far as temp and TDS prior to membrane. Did you happen to check your post membrane TDS as well?I just purged the membrane for 15 minutes. I disconnected the water line after the sediment and carbon blocks and prior to pressure gauge/membrane. Temp at that point is 81F. The TDS is 163PPM.

As far as ambient temp in the area, It's 84 right now so afternoon definitely higher.

Will do it shortly.

104 post TDSWill do it shortly.

And my TDS after the DI just climbed to 6

I changed it yesterday and made 60 gallons of RO/DI

I changed it yesterday and made 60 gallons of RO/DI

Will do it shortly.

geez! so you've got a rejection rating of only 36%.104 post TDS

So unless that membrane is seated in the housing incorrectly, or you have a bad seal and water is bypassing the membrane, then that membrane is toast.

Similar threads

- Replies

- 2

- Views

- 122

- Replies

- 9

- Views

- 187

- Replies

- 7

- Views

- 446