Very nice guys! Sounds like a great project. Can you get a glass bed and a heater for it? (does it come with the heated bed?)

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Get any part you need, right here!

- Thread starter sbash

- Start date

- Tagged users None

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

Yeah mate it comes with a 12v heated bed so it can print PETG and ABS etc. I have also put a piece of glass on top of the bed and it's working really well.Very nice guys! Sounds like a great project. Can you get a glass bed and a heater for it? (does it come with the heated bed?)

I am surprised there has not been more activity in this thread. My attempts and reslicing/resizing and creating items to be printed have been mixed at best so far.

I am surprised there has not been more activity in this thread. My attempts and reslicing/resizing and creating items to be printed have been mixed at best so far.

It is a funny art for sure. What printer do you have and what software are you using?

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

That sucks that you've had mixed results. Keep working at it and you will get there.I am surprised there has not been more activity in this thread. My attempts and reslicing/resizing and creating items to be printed have been mixed at best so far.

Personally I don't bother with resizing stuff, if I see something on thingiverse that I want to print and I don't know for sure it will fit my needs I just re-draw it in Fusion myself, it's a really good way to improve my CAD skills as well and I can make small changes where I want.

So far I have only printed a couple of things for my tank. I a have printed a ATO float switch holder (I don't have any pics of it).

A feeding ring in PLA which has been in the tank for a bit over 4 months now and shows no signs of degrading. It was also a bad print (quite under extruded) so if it does degrade, it will be noticeable as the gaps already in the walls would get bigger faster, but so far there is no more holes in the side than when I first printed it.

Because that looks to be doing ok I decided to step it up and print a nitrate reactor with PLA. This will house massive amounts of bacteria so if anything made out of PLA would degrade, this will be it! It's only been in the tank for a couple of weeks now so I'm keen to see how it goes.

I've also printed a light bracket for my fuge light. This isn't in contact with salt water, but heat was a concern. The light socket itself doesn't get over 30 degrees but I'm keeping an eye on it. 3 weeks so far and no signs of deformation.

I should also finally get onto printing out the final housing and power boards for my Reef-Pi build soon

I have a ultramaker 2+ and cura for slicing. I have tried designing and editing items with a half dozen different software at least. The last one was the worst. I wanted to enlarge Https://www.thingiverse.com/1784377 to about twice the size to fit 1" PVC. I tried 1 program and was not happy with the results. Then I tried 3Dslash. If felt like it was developed for kids, but I could not get it to do a relatively simple thing. I spent at least 2 hours and got abasolute crap for results. The very limited help available was useless!It is a funny art for sure. What printer do you have and what software are you using?

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

Are your issues with the models or the printer? Can you print things like calibration cubes, benchys, temp towers, stress tests etc with no issues? If not then go back to the basics printing those and iron out any issues that arise, while ultimakers are supposed to be pretty good printers I've seen some pretty bad prints come off them before because they weren't set up right. Once you are getting good, consistent prints with those kinds of models then move on to other things.I have a ultramaker 2+ and cura for slicing. I have tried designing and editing items with a half dozen different software at least. The last one was the worst. I wanted to enlarge Https://www.thingiverse.com/1784377 to about twice the size to fit 1" PVC. I tried 1 program and was not happy with the results. Then I tried 3Dslash. If felt like it was developed for kids, but I could not get it to do a relatively simple thing. I spent at least 2 hours and got abasolute crap for results. The very limited help available was useless!

If you are getting good prints with everything else did you try and simply increase the scale in cura instead of in design software? Is it only this model or have you tried some more basic models as well and increasing the scale of them isn't working as well?

As for design software I really wouldn't use anything other than Fusion 360. It can look a little complicated at first but the basics are quite easy to get a hang of and you can learn to use the other features as you need them.

I have a ultramaker 2+ and cura for slicing. I have tried designing and editing items with a half dozen different software at least. The last one was the worst. I wanted to enlarge Https://www.thingiverse.com/1784377 to about twice the size to fit 1" PVC. I tried 1 program and was not happy with the results. Then I tried 3Dslash. If felt like it was developed for kids, but I could not get it to do a relatively simple thing. I spent at least 2 hours and got abasolute crap for results. The very limited help available was useless!

Are your issues with the models or the printer? Can you print things like calibration cubes, benchys, temp towers, stress tests etc with no issues? If not then go back to the basics printing those and iron out any issues that arise, while ultimakers are supposed to be pretty good printers I've seen some pretty bad prints come off them before because they weren't set up right. Once you are getting good, consistent prints with those kinds of models then move on to other things.

If you are getting good prints with everything else did you try and simply increase the scale in cura instead of in design software? Is it only this model or have you tried some more basic models as well and increasing the scale of them isn't working as well?

As for design software I really wouldn't use anything other than Fusion 360. It can look a little complicated at first but the basics are quite easy to get a hang of and you can learn to use the other features as you need them.

I have heard good things about Fusion 360. I use sketchup for most of my parts, but it certainly has its limitations; for example, designing an auger is extremely difficult. I have some projects I have been putting off until I find a better program for shape manipulation.

The cura scaling is a good tip, I find it works quite well.

So yeah, download a calibration tube and a benchy, post it up, hopefully we can help you iron out the issues!

Hey @maccapopeye.62810! Did you find your nitrate reactor on Thingiverse or did you design it yourself?

Agreed, let's see some details about it!Hey @maccapopeye.62810! Did you find your nitrate reactor on Thingiverse or did you design it yourself?

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

I can't say how easy fusion is at drawing augers but I used to use sketch up (very badly) and moving across to fusion I found it really intuitive and way easier to use (the basic aspects of it at least). Lars Christensen also has some seriously awesome tutorial videos on YouTube and I found the way he explains things to be really easy to follow, so maybe check out his channel and see if any of his videos can help you out. Other wise there is a pretty big user base and almost every time I have a question it has already been asked.I have heard good things about Fusion 360. I use sketchup for most of my parts, but it certainly has its limitations; for example, designing an auger is extremely difficult. I have some projects I have been putting off until I find a better program for shape manipulation.

I drew the designs myself, but based it off of Donovan's Poor Mans Nitrate Destroyer here on R2R. I put his name on it as a credit to him / tribute (he passed away collecting coral a few months ago). His designs are on page 1 of this thread and my post is #756:Hey @maccapopeye.62810! Did you find your nitrate reactor on Thingiverse or did you design it yourself?

https://www.reef2reef.com/threads/p...rol-donovans-nitrate-destroyer.302685/page-38

I also uploaded the files here:

https://www.thingiverse.com/thing:2937243

I have printed 2 dozen different items successfully with the only issues I have had been with the material not feeding off the spool on two occasions. The spool not rotating freely causing it not to feed.Are your issues with the models or the printer? Can you print things like calibration cubes, benchys, temp towers, stress tests etc with no issues? If not then go back to the basics printing those and iron out any issues that arise, while ultimakers are supposed to be pretty good printers I've seen some pretty bad prints come off them before because they weren't set up right. Once you are getting good, consistent prints with those kinds of models then move on to other things.

If you are getting good prints with everything else did you try and simply increase the scale in cura instead of in design software? Is it only this model or have you tried some more basic models as well and increasing the scale of them isn't working as well?

As for design software I really wouldn't use anything other than Fusion 360. It can look a little complicated at first but the basics are quite easy to get a hang of and you can learn to use the other features as you need them.

I have used cura to resize some things in the past successfully. I tried using drsign software as I wanted to modify the design a little also. I believe I have tried fusion 360 in the past. I will look at it again.

I jave used sketchup a bit for a few other projects, but have been unable to do what I consider simple designs for 3D printing. I want to make some simple mounting brackets for Tunze and other power supplies. I want to mount them vertically on edge, so they take up the least room possible. Basicly a vertical box with the front mostly open, a opening at the bottom and a slot at the top for the cables. Two counter bored screw holes in the back to mount them. It takes 2 min to draw it out. But my efforts to design using 3D software have been very frustrating. To the point I almost feel I must be mentality challenged.I have heard good things about Fusion 360. I use sketchup for most of my parts, but it certainly has its limitations; for example, designing an auger is extremely difficult. I have some projects I have been putting off until I find a better program for shape manipulation.

The cura scaling is a good tip, I find it works quite well.

So yeah, download a calibration tube and a benchy, post it up, hopefully we can help you iron out the issues!

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

If you have printed lots of other items successfully in the past with good quality then it will likely be an issue with the model itself, I haven't printed it so I can't say for sure but maybe there is bits inside it that just don't scale well or maybe the model is just incomplete? It could also be the modifications you tried to make?I have printed 2 dozen different items successfully with the only issues I have had been with the material not feeding off the spool on two occasions. The spool not rotating freely causing it not to feed.

I have used cura to resize some things in the past successfully. I tried using drsign software as I wanted to modify the design a little also. I believe I have tried fusion 360 in the past. I will look at it again.

It's hard to say without knowing exactly what the issues are, your slicer settings and what size you tried to scale it up to etc. but personally I would just try to find a different model

I'm sure we have all felt that way at one point or anotherI jave used sketchup a bit for a few other projects, but have been unable to do what I consider simple designs for 3D printing. I want to make some simple mounting brackets for Tunze and other power supplies. I want to mount them vertically on edge, so they take up the least room possible. Basicly a vertical box with the front mostly open, a opening at the bottom and a slot at the top for the cables. Two counter bored screw holes in the back to mount them. It takes 2 min to draw it out. But my efforts to design using 3D software have been very frustrating. To the point I almost feel I must be mentality challenged.

I never even tried to print it. It came out so bad I knew it would not print well. Looking up Lars Christensen‘s videos on fusion now. ThanksIf you have printed lots of other items successfully in the past with good quality then it will likely be an issue with the model itself, I haven't printed it so I can't say for sure but maybe there is bits inside it that just don't scale well or maybe the model is just incomplete? It could also be the modifications you tried to make?

It's hard to say without knowing exactly what the issues are, your slicer settings and what size you tried to scale it up to etc. but personally I would just try to find a different model

I'm sure we have all felt that way at one point or anotherI really recommend fusion paired with some of Lars Christensen's tutorial videos. Once you get the basics down it's a million times easier than sketch up. And the history timeline down the bottom is amazing for saving time if you get to the end of a design and realise you make one small mistake at the start.

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

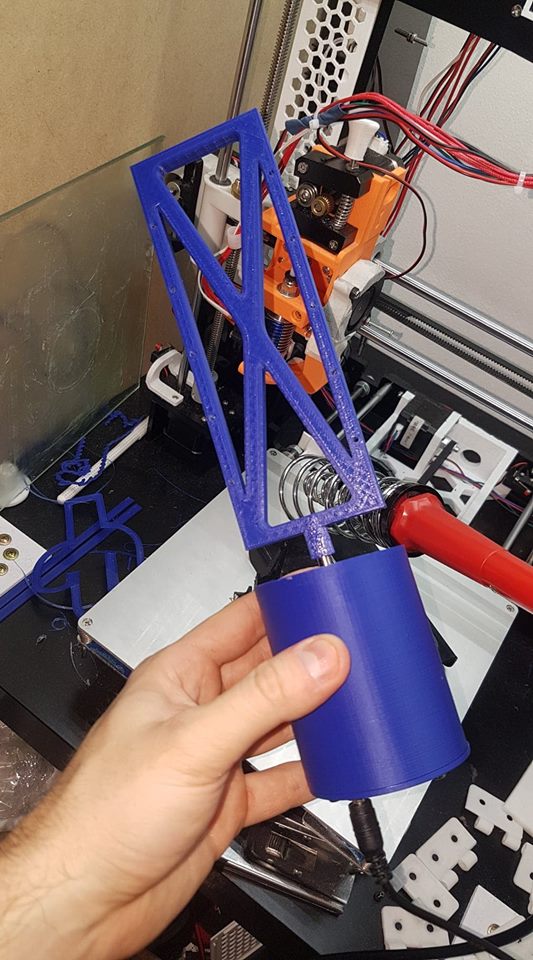

Almost finished my DIY skimmer neck cleaner (the swabbie idea came from FishOfHex on YouTube, I just designed a housing for it). Total cost is around $20 AUD for the motor, power supply, filament, knitting mesh and electrical connections etc.

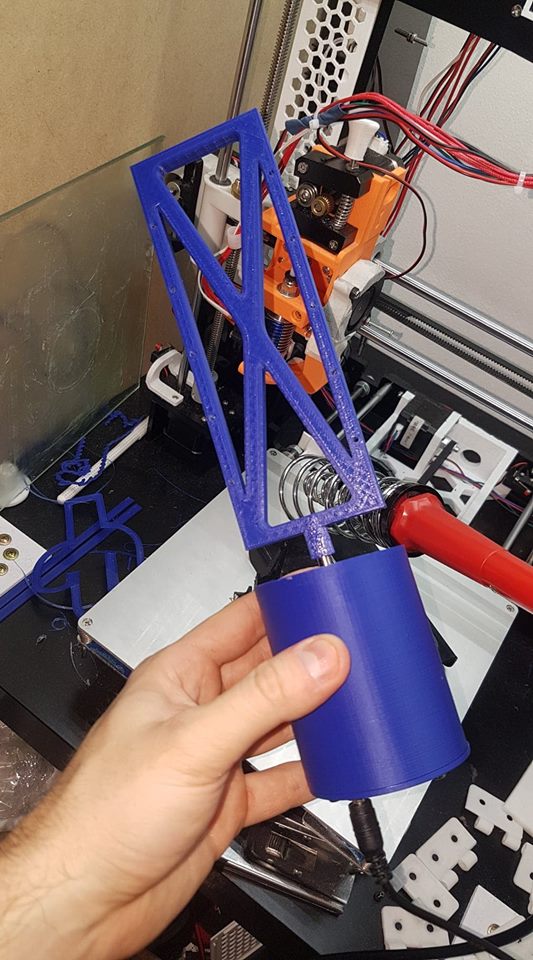

A photo of the motor inside the housing. Other parts are in the background.

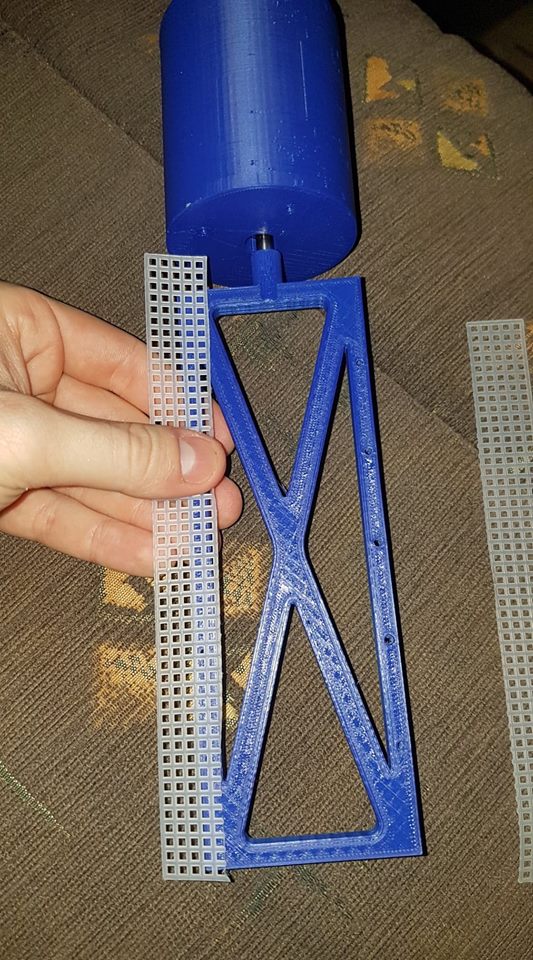

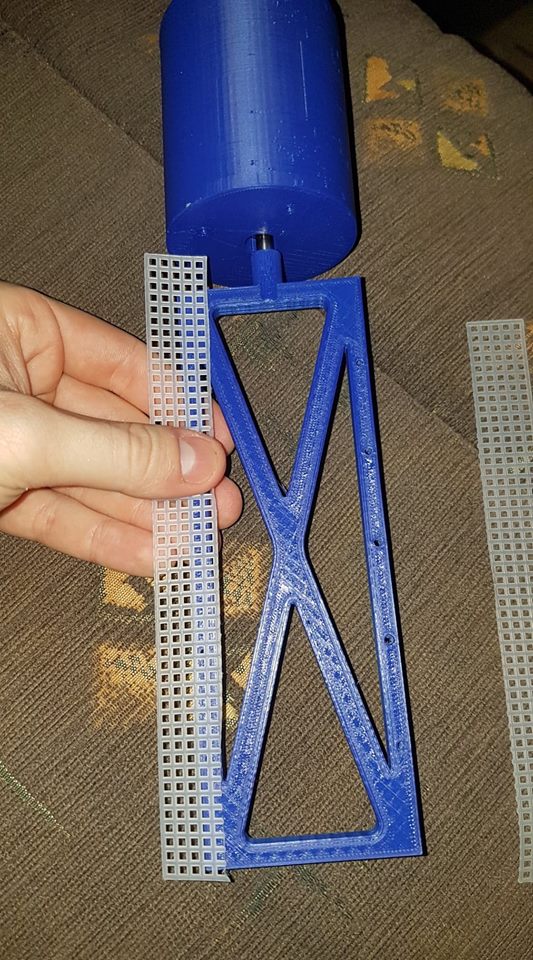

Photo of the knitting mesh that will be glued on the sides to actually scrape off the skimmer scum.

Photo of the assembled piece (minus the knitting mesh) after I finished the wiring inside the housing.

And a very quick video of the swabbie spinning. The motor in the video sounds quite loud because this was filmed inside my 3D printer enclosure, it actually only makes a very soft hum.

I've still got a little bit to do (I might re-print the part that spins inside the neck and make it thinner) and then I need to get it on the skimmer. Once it's all finished I will upload the STL to Thingiverse

A photo of the motor inside the housing. Other parts are in the background.

Photo of the knitting mesh that will be glued on the sides to actually scrape off the skimmer scum.

Photo of the assembled piece (minus the knitting mesh) after I finished the wiring inside the housing.

And a very quick video of the swabbie spinning. The motor in the video sounds quite loud because this was filmed inside my 3D printer enclosure, it actually only makes a very soft hum.

I've still got a little bit to do (I might re-print the part that spins inside the neck and make it thinner) and then I need to get it on the skimmer. Once it's all finished I will upload the STL to Thingiverse

Almost finished my DIY skimmer neck cleaner (the swabbie idea came from FishOfHex on YouTube, I just designed a housing for it). Total cost is around $20 AUD for the motor, power supply, filament, knitting mesh and electrical connections etc.

A photo of the motor inside the housing. Other parts are in the background.

Photo of the knitting mesh that will be glued on the sides to actually scrape off the skimmer scum.

Photo of the assembled piece (minus the knitting mesh) after I finished the wiring inside the housing.

And a very quick video of the swabbie spinning. The motor in the video sounds quite loud because this was filmed inside my 3D printer enclosure, it actually only makes a very soft hum.

I've still got a little bit to do (I might re-print the part that spins inside the neck and make it thinner) and then I need to get it on the skimmer. Once it's all finished I will upload the STL to Thingiverse

Looks great. Has mesh proven to work better the the flexible material of a squeegee?

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

I dont think it will work better. But it certainly seems to do the job fine and I already had some laying aroundLooks great. Has mesh proven to work better the the flexible material of a squeegee?

FishOfHex showed that his neck is still pretty dang clean after a month of using it and he used the mesh. It's also got the added benefit (due to the holes) that as it spins, hopefully gunk will fall off it and back into the skimmer more easily than on a squeegee (I've see it really build up on them).

But if I'm not happy with it in a couple of months I can always print another one and attach a squeegee to it instead

I can see where it could be advantageous now. Thsnks

One of the things I would like to print is a custom lid for my skimmer. It would include neck cleaner in its design. Although that would probably be after I tested and proved some other changed first.

One of the things I would like to print is a custom lid for my skimmer. It would include neck cleaner in its design. Although that would probably be after I tested and proved some other changed first.

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

I am actually tempted to print a whole lid for it rather than drill into the current one, then worst case scenario I don't ruin my skimmer lidI can see where it could be advantageous now. Thsnks

One of the things I would like to print is a custom lid for my skimmer. It would include neck cleaner in its design. Although that would probably be after I tested and proved some other changed first.

Similar threads

- Replies

- 2

- Views

- 104

- Replies

- 3

- Views

- 117

- Replies

- 17

- Views

- 654

- Replies

- 11

- Views

- 712

- Replies

- 7

- Views

- 531