- Joined

- Feb 27, 2016

- Messages

- 69

- Reaction score

- 72

Hey everyone, this will be a build thread for my 210g tank with a remote basement sump. This is definitely my (realistic) dream tank and I'd really like to get everything right. Since my wife and I are expecting the goal for this tank is to automate wherever possible and anything remaining should be as easy as possible. At this point in the hobby I'm really looking to spend more time just enjoying the tank than fiddling with everything and constantly having a to-do list.

Tanks

210g Display

40g Breeder Frag Tank

Lighting

2x ReefBreeders Photon V2+ 36"

Flow

2x IceCap 4K Gyres

2x Jebao RW-8's

Reeflo Barracuda

Filtration

Coral Box Cloud C9 Skimmer

ATS (WIP)

Other

Apex Controller

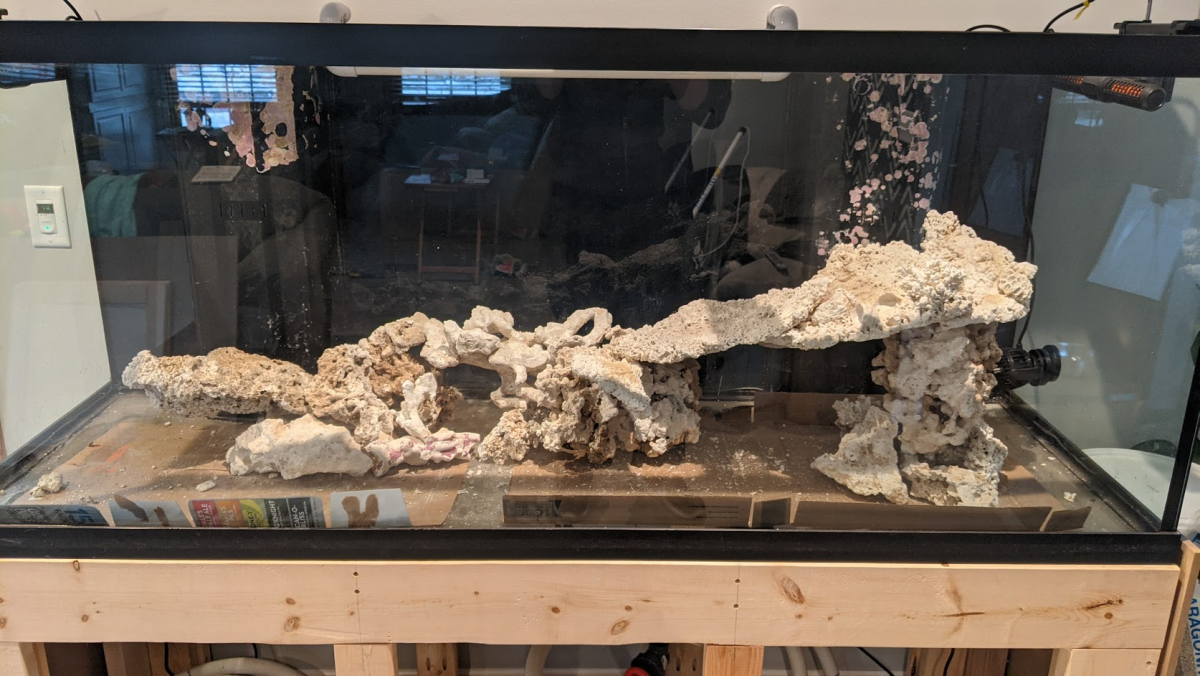

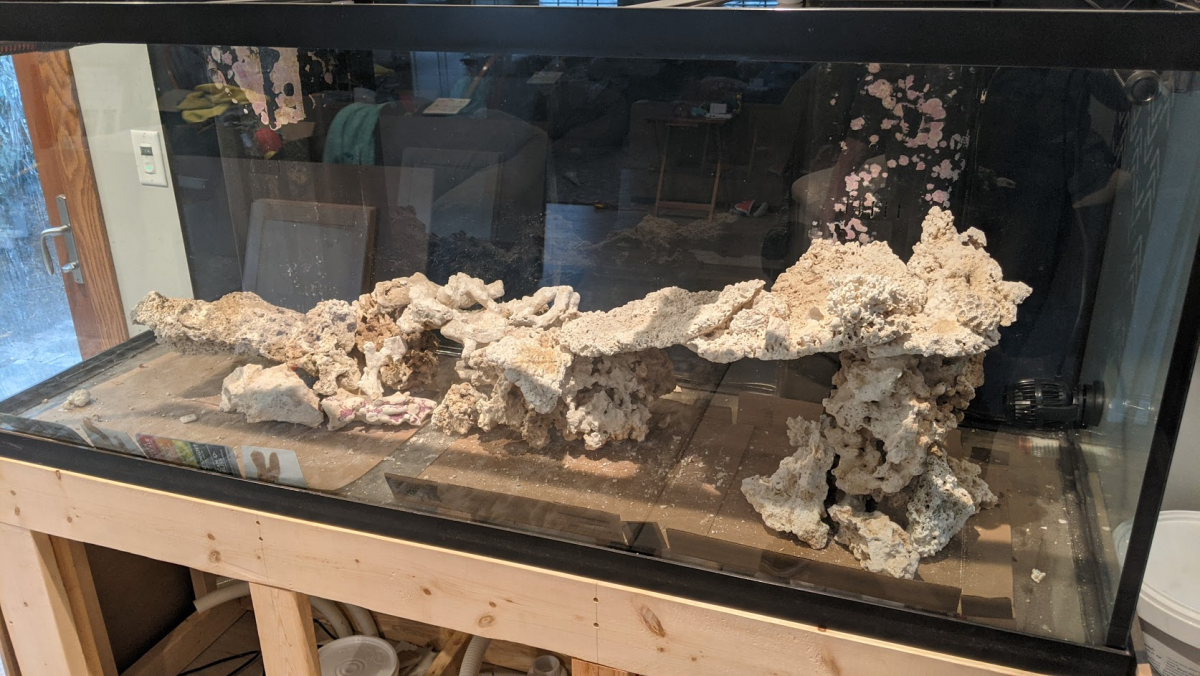

To start, here's what I'm thinking for the aquascape, any feedback is welcome! I'm planning on doing a lot of sticks and thinks so I'm leaning towards keeping the scape pretty minimal and low to allow some grow out room.

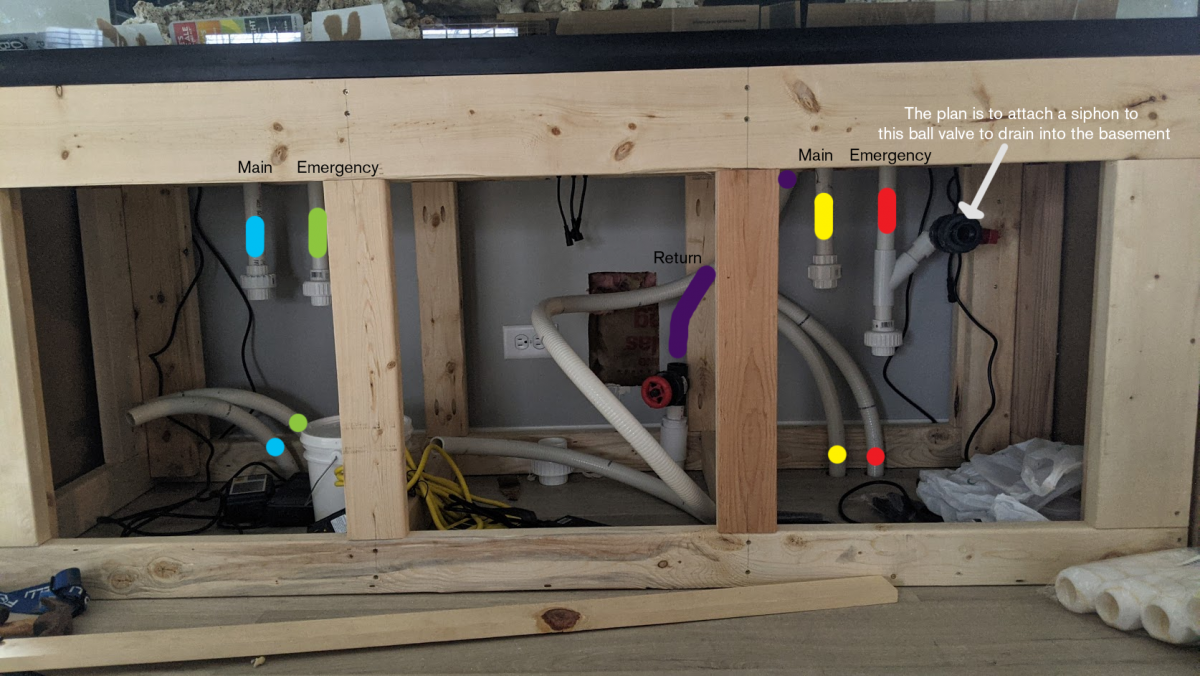

And then to the biggest thing for me at the moment, the plumbing. I'd say I have everything about 85-90% done and dry fit and figured it would be good to post it and see if anyone had feedback, thoughts or changes. I've never done a remote sump so I'm definitely a little out of my wheelhouse on some of this.

I'm planning on running both overflows with Herbies, and bringing the return line up behind the tank. I don't have the flexline cut to size and dry fit quite yet because the bend in the hose puts a lot of pressure on the bulkheads. When I do the final cut to length, I'm planning on soaking all the lines in hot water since that seems to help reform the memory on them. All drains are 1" and the return pressure line is 1.5" up to this point, and then reduces to 1" to go up above the tank.

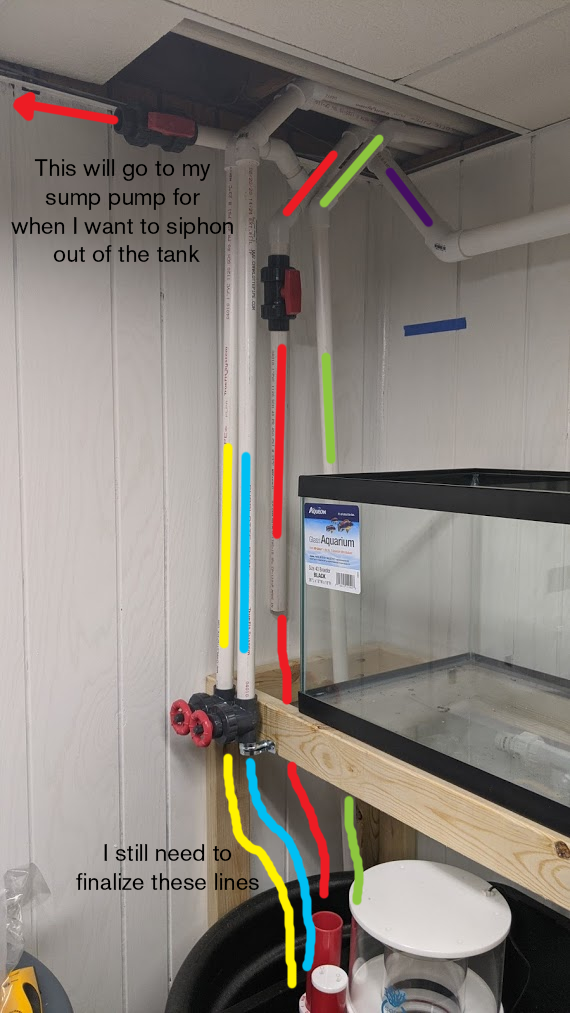

In order to make things easy, and because my wife hates me hauling buckets around, I want to build in a siphon I can open to clean the tank and have it drain into the house sump. The majority of the actual water changes I'm going to handle in the basement with the Apex, but want to be able to manually clean sand or suck out detritus up top when needed.

Flexline comes down into standard hard line under the floor, all double 45's to help in whatever small amount for throughput.

So I'm super fortunate to have a very large finished furnace room which has ample space to build out my sump area. I painted the walls around the sump in extra high gloss to prevent the wood from becoming damaged and causing issues. Someday we'd like to remodel the basement to get rid of the super 90's wood paneling, but inside the furnace room I'm okay keeping it as long as it doesn't get ruined, hence the protection. The space around the supplyhouse box I'm planning on putting a 20g quarantine tank in the future.

So here you can see my plan to use the one emergency line (red) with its secondary function of cleaning siphon. I could open the ball valve under the tank, close the one to the fish sump and then open the one that leads to the house sump. I did the funky T off of the 45 hoping that if I were to suck up anything like gravel or a snail shell it would be caught in the lower area and eventually go into the fish sump rather than going into my house sump and causing issues with that. I'm planning on having both lines end with a filter sock to be double safe, but figured this could help as well. The two main lines will drain into my upper bin with the skimmer and then into the larger 100g rubbermaid.

Here you can see I'm planning on running a 4 port manifold off of the barracuda. My plan is for one port to run the frag tank, one port to run a DIY Algae Turf Scrubber, and then have two left over for future expansions of reactors/sterilizers/etc.

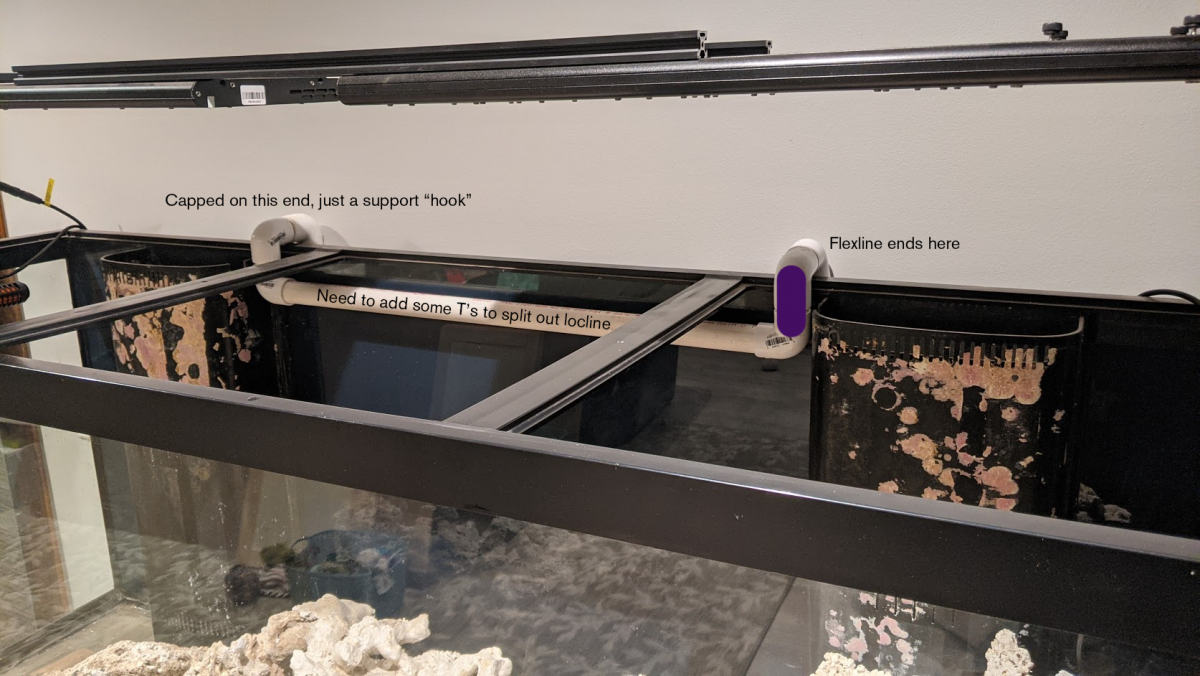

And here is the plan for getting the water into the tank, I forgot to get the T's for this so for now its just a bar. I have 3 Y sections of locline for 6 total ports I can attach and angle for lots of flow.

So thats where I'm at for now! If anyone has any suggestions, comments or helpful tips on the plumbing that would be great. I'm hoping to finalize and start the glue up over the next few days. For now the next project will be to run some copper lines to the utility sink and get the RODI unit down there.

Tanks

210g Display

40g Breeder Frag Tank

Lighting

2x ReefBreeders Photon V2+ 36"

Flow

2x IceCap 4K Gyres

2x Jebao RW-8's

Reeflo Barracuda

Filtration

Coral Box Cloud C9 Skimmer

ATS (WIP)

Other

Apex Controller

To start, here's what I'm thinking for the aquascape, any feedback is welcome! I'm planning on doing a lot of sticks and thinks so I'm leaning towards keeping the scape pretty minimal and low to allow some grow out room.

And then to the biggest thing for me at the moment, the plumbing. I'd say I have everything about 85-90% done and dry fit and figured it would be good to post it and see if anyone had feedback, thoughts or changes. I've never done a remote sump so I'm definitely a little out of my wheelhouse on some of this.

I'm planning on running both overflows with Herbies, and bringing the return line up behind the tank. I don't have the flexline cut to size and dry fit quite yet because the bend in the hose puts a lot of pressure on the bulkheads. When I do the final cut to length, I'm planning on soaking all the lines in hot water since that seems to help reform the memory on them. All drains are 1" and the return pressure line is 1.5" up to this point, and then reduces to 1" to go up above the tank.

In order to make things easy, and because my wife hates me hauling buckets around, I want to build in a siphon I can open to clean the tank and have it drain into the house sump. The majority of the actual water changes I'm going to handle in the basement with the Apex, but want to be able to manually clean sand or suck out detritus up top when needed.

Flexline comes down into standard hard line under the floor, all double 45's to help in whatever small amount for throughput.

So I'm super fortunate to have a very large finished furnace room which has ample space to build out my sump area. I painted the walls around the sump in extra high gloss to prevent the wood from becoming damaged and causing issues. Someday we'd like to remodel the basement to get rid of the super 90's wood paneling, but inside the furnace room I'm okay keeping it as long as it doesn't get ruined, hence the protection. The space around the supplyhouse box I'm planning on putting a 20g quarantine tank in the future.

So here you can see my plan to use the one emergency line (red) with its secondary function of cleaning siphon. I could open the ball valve under the tank, close the one to the fish sump and then open the one that leads to the house sump. I did the funky T off of the 45 hoping that if I were to suck up anything like gravel or a snail shell it would be caught in the lower area and eventually go into the fish sump rather than going into my house sump and causing issues with that. I'm planning on having both lines end with a filter sock to be double safe, but figured this could help as well. The two main lines will drain into my upper bin with the skimmer and then into the larger 100g rubbermaid.

Here you can see I'm planning on running a 4 port manifold off of the barracuda. My plan is for one port to run the frag tank, one port to run a DIY Algae Turf Scrubber, and then have two left over for future expansions of reactors/sterilizers/etc.

And here is the plan for getting the water into the tank, I forgot to get the T's for this so for now its just a bar. I have 3 Y sections of locline for 6 total ports I can attach and angle for lots of flow.

So thats where I'm at for now! If anyone has any suggestions, comments or helpful tips on the plumbing that would be great. I'm hoping to finalize and start the glue up over the next few days. For now the next project will be to run some copper lines to the utility sink and get the RODI unit down there.