Nice sump Niterunner!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How is everyone building a stand so cheap?

- Thread starter timrocks311

- Start date

- Tagged users None

- Joined

- Apr 4, 2017

- Messages

- 94

- Reaction score

- 28

I bought the steel stand for the 40 breeder at Petco and put a skin on the sides and added the doors.

https://www.petco.com/shop/en/petcostore/product/imagitarium-brooklyn-metal-tank-stand-40-gallons

Albert

https://www.petco.com/shop/en/petcostore/product/imagitarium-brooklyn-metal-tank-stand-40-gallons

Albert

- Joined

- Jul 25, 2017

- Messages

- 530

- Reaction score

- 334

- Joined

- Dec 3, 2015

- Messages

- 152

- Reaction score

- 171

Thanks so much!Nice sump Niterunner!

I made my stand for about $50 lol

I nailed some 2x3 together to make the top.

And bought some inexpensive sawhorse legs from IKEA .

LOL, thats awesome. Industrial minimalist style.

redfishbluefish

Stay Positive, Stay Productive

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Article Contributor

NJRC Member

Hospitality Award

My Tank Thread

This thread has peaked my interest in what I'm spending on a current stand build. I never gave it much thought since I needed a stand, and building one, with the five thousand plus dollars I've spent on tools, just seemed like the right thing to do, with little regard for the material costs. In addition, I've always wanted a taller than commercially available stand height. The stand I'm building now is for a 35 cube and measures 21 x 19 x 39 1/2 inches.

Here's what I've spent so far (with what you see above)

3----1" x 3" x 16' finger jointed / primed boards (HD)-----$10.44 each-------$31.32

1----1" x 6" x 8' finger jointed/ primed board (HD)--------$11.22 each-------$11.22

1----4' x 8' x 5mm Poplar plywood (Lowes)-----------------$13.98 each-------$13.98

TOTAL-----------------------------------------------------------------------------$56.52

Wow! More than I would have guessed. I liked it better when I didn't know!

I've used about half the plywood and have about ten feet of 1 x 3 left over. The 3/4 furniture grade plywood on the top and floor were left over from another project, as were the eight 12mm Neo magnets (holding the door closed) that were purchased from China in large quantity for cheap. I haven't included costs for polyurethane glue, epoxy cement, nails and screws. Still need to fill screw holes (putty), prime and paint the stand....and then build the canopy.

Here's what I've spent so far (with what you see above)

3----1" x 3" x 16' finger jointed / primed boards (HD)-----$10.44 each-------$31.32

1----1" x 6" x 8' finger jointed/ primed board (HD)--------$11.22 each-------$11.22

1----4' x 8' x 5mm Poplar plywood (Lowes)-----------------$13.98 each-------$13.98

TOTAL-----------------------------------------------------------------------------$56.52

Wow! More than I would have guessed. I liked it better when I didn't know!

I've used about half the plywood and have about ten feet of 1 x 3 left over. The 3/4 furniture grade plywood on the top and floor were left over from another project, as were the eight 12mm Neo magnets (holding the door closed) that were purchased from China in large quantity for cheap. I haven't included costs for polyurethane glue, epoxy cement, nails and screws. Still need to fill screw holes (putty), prime and paint the stand....and then build the canopy.

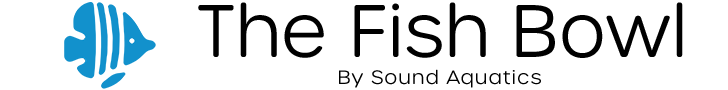

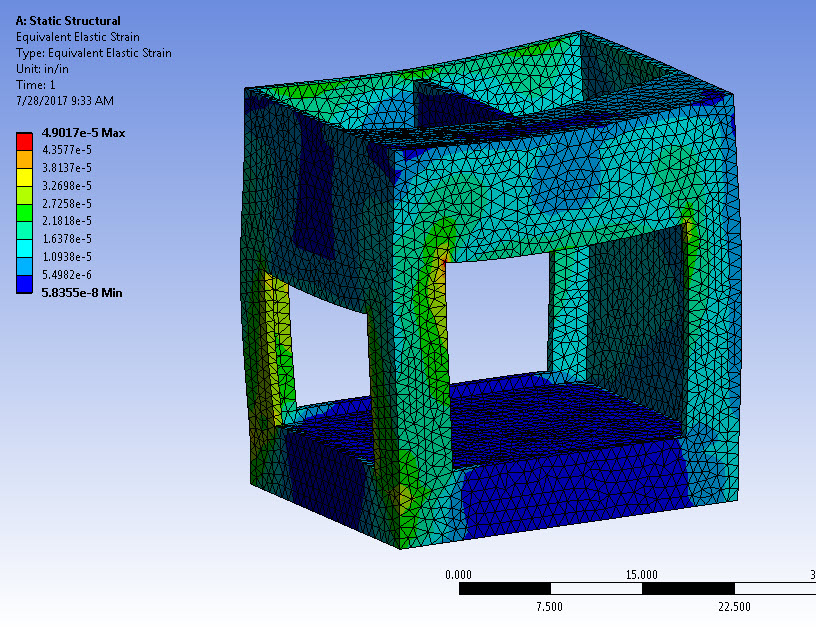

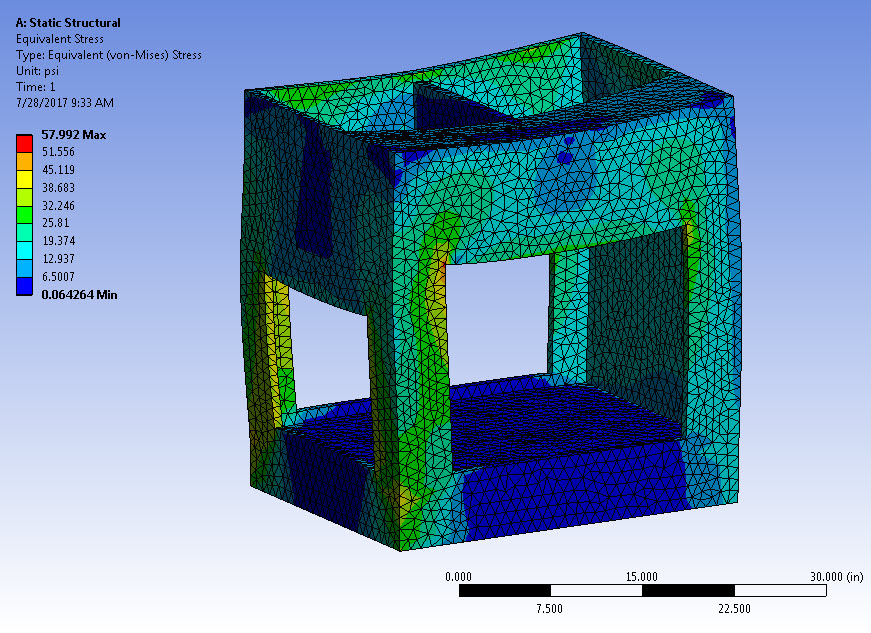

So, I have analyzed an approximation of the stand that I built that's shown earlier in this thread.

The body is contiguous, IE. no joints analyzed. From experience, I know that proper joints are stronger than the material itself. You will see the major components of stress are contained in areas with no fasteners.

The bottom of the stand is fixed in all directions (Could be friction in the planar floor and fixed in vertical to be more accurate but insignificant.)

There is a load of 700 lbf in the -Z direction (down). This is 78 gallons of water +50 lbf for conservatism. (Static loading scenario)

The image deflection is magnified by a factor of 2200 so that you can see whats going on. It is not deflecting like what you see.

Fig. 1. Equivalent Strain. Maximum strain occurs in the upper corners of the front opening @ approx .000049 in/in.

Fig. 2. Equivalent Stress. 57.22 psi, located in the same area as max strain.

Fig. 3. Total deformation. Just over one thousandths of an inch deformation in the red area shown.

The material used is isotropic (Plywood is isotropic due to manufacturing method, solid wood IS NOT due to grain direction.)

Ultimate Tensile Strength of Oak is 770 PSI

770/57.22 = Safety Factor of 13.45

Conclusion: Given sufficient and properly implemented fasteners (Properly sized dowel holes, glue, proper size pilot holes for screws, sufficient number of fasteners) A 3/4" Oak plywood stand is more than sufficient for this application. I would even venture to say that under disturbed conditions (Small seismic event) That this stand would have no problems with a safety factor of 10x +.

I don't even see a reason why to move forward to analyzing a 2x4 constructed stand, as it is overkill and unwarranted. Costs space money and time.

Disclaimer: I am not responsible for any damage occurring in relationship to this information, use at your own risk.

The body is contiguous, IE. no joints analyzed. From experience, I know that proper joints are stronger than the material itself. You will see the major components of stress are contained in areas with no fasteners.

The bottom of the stand is fixed in all directions (Could be friction in the planar floor and fixed in vertical to be more accurate but insignificant.)

There is a load of 700 lbf in the -Z direction (down). This is 78 gallons of water +50 lbf for conservatism. (Static loading scenario)

The image deflection is magnified by a factor of 2200 so that you can see whats going on. It is not deflecting like what you see.

Fig. 1. Equivalent Strain. Maximum strain occurs in the upper corners of the front opening @ approx .000049 in/in.

Fig. 2. Equivalent Stress. 57.22 psi, located in the same area as max strain.

Fig. 3. Total deformation. Just over one thousandths of an inch deformation in the red area shown.

The material used is isotropic (Plywood is isotropic due to manufacturing method, solid wood IS NOT due to grain direction.)

Ultimate Tensile Strength of Oak is 770 PSI

770/57.22 = Safety Factor of 13.45

Conclusion: Given sufficient and properly implemented fasteners (Properly sized dowel holes, glue, proper size pilot holes for screws, sufficient number of fasteners) A 3/4" Oak plywood stand is more than sufficient for this application. I would even venture to say that under disturbed conditions (Small seismic event) That this stand would have no problems with a safety factor of 10x +.

I don't even see a reason why to move forward to analyzing a 2x4 constructed stand, as it is overkill and unwarranted. Costs space money and time.

Disclaimer: I am not responsible for any damage occurring in relationship to this information, use at your own risk.

Last edited:

- Joined

- Jul 29, 2017

- Messages

- 1

- Reaction score

- 4

I purchased a restaurant grade stainless steel table for my 150g, bolted to the wall supported the center with a 6 x 6 covered with faux stone and mounted two led accent lights underneath. I think I'm in @$350.

I used 1/2" ply supported by a 1x4 frame. But I'm only supporting 25 gallons. Including appearance boards, hinges, and paint I'm right around $175. Not crazy cheap, but still cheaper than most of the weak particle board stands.

What do you think about using Baltic Birch Plywood? I'm thinking about using it, since it's beautiful and stronger than normal plywood. Although, it's a lot more expensive.I build all of my stands with 3/4"oak plywood. I use pilot/screws alternating with spec sized holes for dowel and glue. Between the screws and the glued dowels, there won't be a problem. I am a mechanical engineer and have a good intuition on loading and such but if you are reasonable.... I have 100 bucks in plywood and a little bit of glue/hardware/paint in this....

The first pic is upside down, notice the floor is fully boxed and attached from all sides.

The second pic is reinforced in the for aft direction and boxed above the large opening in the front to mitigate loading around the front opening.

Its solid as a rock for under $150 and a few afternoons by the time its painted.

- Joined

- Jul 1, 2015

- Messages

- 693

- Reaction score

- 427

Just note if you buy through Amazon you will pay full list price. Go through the Tslot website and find a distributor, the process take a little longer but will save you tons of cash. For example a connector I needed was 9.97 on Amazon and through the distributor the same piece was 3.47, so it's worth going through the distributor.This is what my stand uses

https://www.amazon.com/80-20-Inc-T-...rd_wg=huVCi&psc=1&refRID=C3R5R0NKD085CEV5CA82

- Joined

- Jul 1, 2015

- Messages

- 693

- Reaction score

- 427

The molding you have on that alone is a 148My slightly over sized peninsula stand (2x4 & 2x8 frame) for my 180 which includes a sub floor 5 doors and a pull out shelf $148.

Mine is made from scrap fence posts, scaffold boards and pallet wood.

Then i added the pallet wood for the sides and door and a piece of oak counter top.

Added adjustable feet and waxed and it's more or less finished.

In total it cost me around £80 which is about $105 the biggest part of that was the oak top which cost me £50.

Then i added the pallet wood for the sides and door and a piece of oak counter top.

Added adjustable feet and waxed and it's more or less finished.

In total it cost me around £80 which is about $105 the biggest part of that was the oak top which cost me £50.

What a cutie, I love baby in tank pics!

- Joined

- Oct 8, 2016

- Messages

- 1,902

- Reaction score

- 1,343

Use 2x2 or 1x1 it's only a 40b. The only time I would use 2x4 is if the that is over 1000 pounds.

- Joined

- Jul 29, 2017

- Messages

- 31

- Reaction score

- 9

Seeing all these over built stands is starting to get me worried. Here's the original stand for my 240. I used it from 1985 until 1995 when we did some home remodeling and it ended up in storage. It is made of SYP and nailed together.

I am no engineer but recently built this stand using no metal fasteners. Just box joints, dovetails, rabbets, splines and dowels. The top and bottom plate is SYP construction cast offs and the uprights are 1 1/2" Cypress. Titebond 3 and epoxy were also used. I still have doors to make and once the sump is made I might add a couple uprights between the long spans.

I am no engineer but recently built this stand using no metal fasteners. Just box joints, dovetails, rabbets, splines and dowels. The top and bottom plate is SYP construction cast offs and the uprights are 1 1/2" Cypress. Titebond 3 and epoxy were also used. I still have doors to make and once the sump is made I might add a couple uprights between the long spans.

2x4s, 1x2s, plywood and screws.

I only bought the paint, plywood for the outsides and 1 x2s. I think I'm about $115 (the $115 includes the conduit for hanging the lights, as well as a handful of plumbing parts) in so far, but I still have to make doors.

I only bought the paint, plywood for the outsides and 1 x2s. I think I'm about $115 (the $115 includes the conduit for hanging the lights, as well as a handful of plumbing parts) in so far, but I still have to make doors.

Similar threads

- Replies

- 24

- Views

- 748