Very interesting program. I built my last tank inside the wall so both sides of the tank would be flush with the faces of the room. I stress about this big time. If it ever leaked not only would a have to deal with the tank trimmed inside the wall, but it's a permanent fixture of the house, even if I sold the house. I have no idea how much weight it would support, but I am curious. More importantly it staying level after settling, getting a little wet, and supporting 900 lbs for years.So, I have analyzed an approximation of the stand that I built that's shown earlier in this thread.

The body is contiguous, IE. no joints analyzed. From experience, I know that proper joints are stronger than the material itself. You will see the major components of stress are contained in areas with no fasteners.

The bottom of the stand is fixed in all directions (Could be friction in the planar floor and fixed in vertical to be more accurate but insignificant.)

There is a load of 700 lbf in the -Z direction (down). This is 78 gallons of water +50 lbf for conservatism. (Static loading scenario)

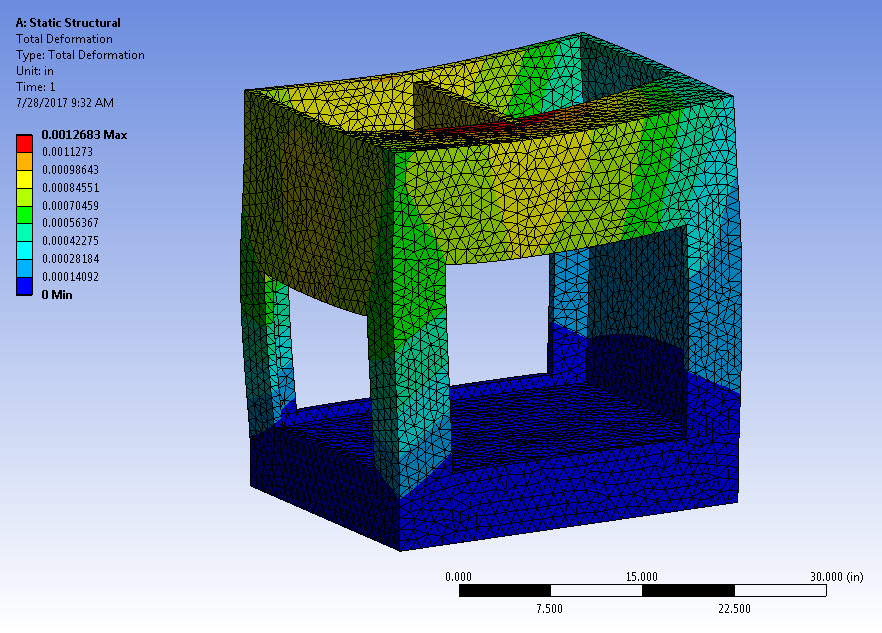

The image deflection is magnified by a factor of 2200 so that you can see whats going on. It is not deflecting like what you see.

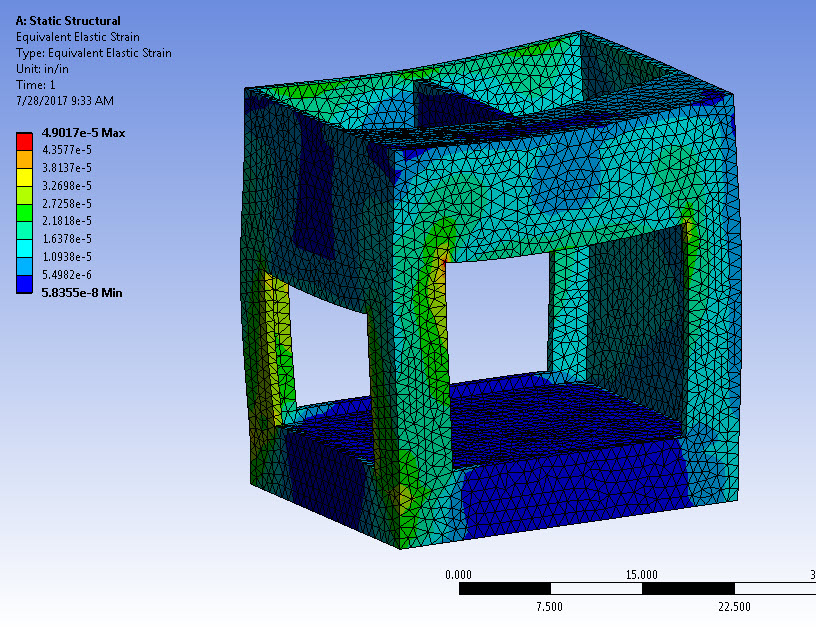

Fig. 1. Equivalent Strain. Maximum strain occurs in the upper corners of the front opening @ approx .000049 in/in.

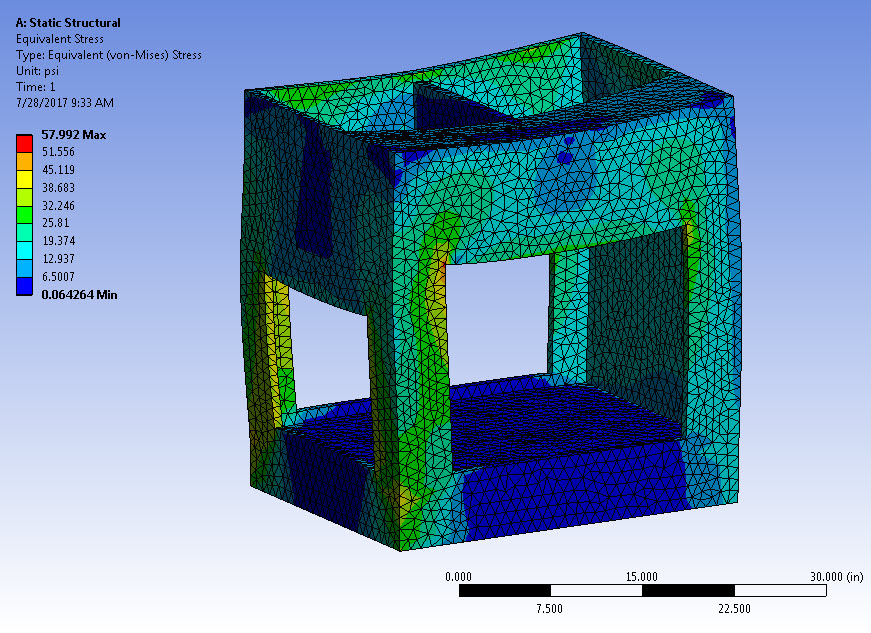

Fig. 2. Equivalent Stress. 57.22 psi, located in the same area as max strain.

Fig. 3. Total deformation. Just over one thousandths of an inch deformation in the red area shown.

The material used is isotropic (Plywood is isotropic due to manufacturing method, solid wood IS NOT due to grain direction.)

Ultimate Tensile Strength of Oak is 770 PSI

770/57.22 = Safety Factor of 13.45

Conclusion: Given sufficient and properly implemented fasteners (Properly sized dowel holes, glue, proper size pilot holes for screws, sufficient number of fasteners) A 3/4" Oak plywood stand is more than sufficient for this application. I would even venture to say that under disturbed conditions (Small seismic event) That this stand would have no problems with a safety factor of 10x +.

I don't even see a reason why to move forward to analyzing a 2x4 constructed stand, as it is overkill and unwarranted. Costs space money and time.

Disclaimer: I am not responsible for any damage occurring in relationship to this information, use at your own risk.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How is everyone building a stand so cheap?

- Thread starter timrocks311

- Start date

- Tagged users None

Yep! Its true. I made the stand for my 125g a few years ago and really cheap using 2x4 from home depot. Then I just put up panel sheets on the sides and velcroed the two front pieces.

And I know I spend less than $100 on everything!

I purchased a restaurant grade stainless steel table for my 150g, bolted to the wall supported the center with a 6 x 6 covered with faux stone and mounted two led accent lights underneath. I think I'm in @$350.

Love me a good ledge

Nah lol. Maybe if we didn't mill some of it ourselves and didn't already have the fluted pieces and hardware left over [emoji6]The molding you have on that alone is a 148

I took a slightly different approach, and picked up an entertainment center from Craigslist to integrate my tank into.

Picked it up for $50, because the guy just wanted to get rid of it and it would have cost him money to dispose of.

All in all, I put about $150 of materials in. $200 and a lot of labor. It'd be more difficult to do with a larger tank, but one could always find a chest online, reinforce it, and customize it.

Picked it up for $50, because the guy just wanted to get rid of it and it would have cost him money to dispose of.

All in all, I put about $150 of materials in. $200 and a lot of labor. It'd be more difficult to do with a larger tank, but one could always find a chest online, reinforce it, and customize it.

I did a 40B with a 40B sump. Stand is 2x4 and the wrap is somesort of 1/8" underlayment stained black and held on with magnets.

That sounds about right... my stand for a 75g and extra cabinet on side, plus trim, primer, paint, caulking, hardware, etc... is around $400. But it is built sturdy and to my specs... the stands you buy from a LFS or elsewhere will still be expensive and usually poorly made! I'm finding that nothing is cheap in this hobby! Pic is the stand I just completed...doors are done, but just not installed yet!

Hey bud. Any chance you have plans of your stand build? Something like that with an extension on both sides (instead of left only like yours) is what I am planning on building.

Would appreciate your help a lot.

Hey bud. Any chance you have plans of your stand build? Something like that with an extension on both sides (instead of left only like yours) is what I am planning on building.

Would appreciate your help a lot.

Sorry, I don't have exact drawn out plans or cut-sheets for the stand I built. I kind of just played it by ear as I went along. I had an idea of the space i was going to place the stand, so that determined my overall width of it. I wanted a cabinet on both sides, but it wouldn't fit in the space I had...but then i ended up putting it somewhere else and could have had another cabinet afterall! I made sure the tank's dimensions would be setting on solid framing, though... so main structure was built to those specifications. I also wanted atall stand, so the bottom of the aquarium sits at 40-41".... gives a lot of room in the sump area for equipment and I don't have to bend down to see under the top rim of the aquarium. I can still reach down in the tank, but a small step is helpful. Here is my build thread with a lot of pictures taken at different steps...it should be helpful for you to see how it was constructed.

www.reef2reef.com/threads/idocs-first-reef-tank-build-75g.317135/

One thing i would change... the extra back section and cabinet...i would use smaller, lighter lumber rsther than 2x4's. There is no structural weight from the tank on these areas...but i had extra 2x4's so I used them. The stand was very heavy.

If you have questions, let me know!

that was awesome build - thank you for sharing. I really appreciate the detail.

Solid oak and oak plywood. Coated with spar varnish, inside and out. Cost? About 350.00-400.00.

- Joined

- May 6, 2017

- Messages

- 531

- Reaction score

- 284

What is the shelf for? Electrical panel?Btw the shelf is the end column up against the wall. You can tell because it is 98% closed lol

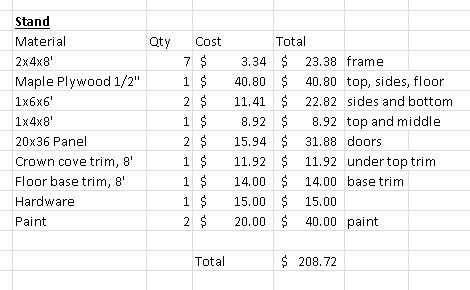

Build a plywood box. 1/2" is done for 40b. I did 3/4" for my 60g and 120g that had a 48x24" footprint.I'm looking to build a typical 2x4 stand for my 40B; nothing super fancy. 1/2" plywood top, sides and sump floor. Two panel doors, some 1x4 trim on the front with some basic decorative trim at the base and under the top. I have all the tools.

I went to Lowe's to price up material and by the time I add in some paint I'm over $200. Man I thought people said it's way cheaper to make your own. How do you do it? How much did you spend?

Much cheaper [emoji6]

My SCA Stand for my 150 that's Furniture grade.

Similar threads

- Replies

- 24

- Views

- 747