- Joined

- Apr 29, 2020

- Messages

- 713

- Reaction score

- 348

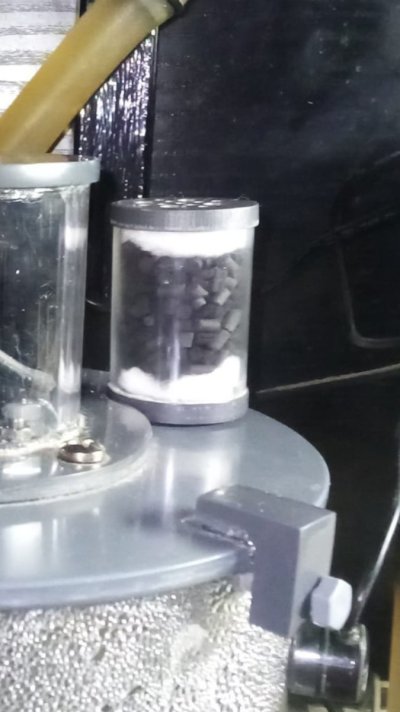

I actually kinda tried that. I Have the jumbo co2 reactor from BRS. I also have a VOSS glass bottle before the co2 reactor to catch all the water before it goes into the reactor. I have actually now taped the bottom cap of the reactor with some ro/di fittings and have the bottle just collect the access water from the bottom. In all configurations the sound was still present. Not more or less. I would post a video of my popcorn maker but I cleaned it yesterday so its behaving.The three skimmers i use in my rotation all have loud air draws which make the sound like you describe if not connected to a silencer or my CO2 reactor. My CO2 reactor has two stages which makes the air intake silent. I ran a single BRS chamber and it was still loud so i had an old RO/DO unit in the garage and decided to run 2 of the cannisters in line to the skimmer. The first chamber 1/2 full of water and the second chamber with the media. The water in the first chamber helps keeps the air moist into the media chamber and the added plus is that it knocks out the air draw noise.

mine is like this but i use a short chamber for the water