indeed a small

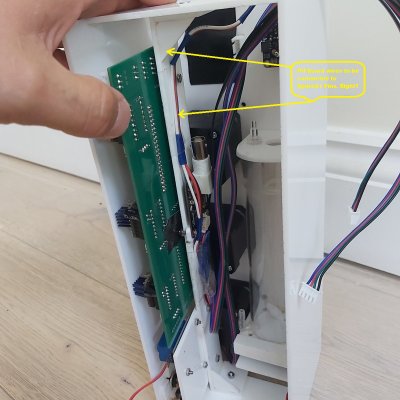

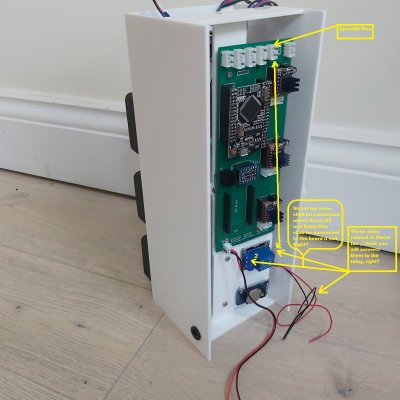

the fan is still preferred as its easier to mount and saves a lot of space. there would be not enough space in my enclosure for other motor unfortunately

indeed a small motor would be better - does not need a lot of torque, its just that fans have almost no torque at all..

the fan is still preferred as its easier to mount and saves a lot of space. there would be not enough space in my enclosure for other motor unfortunately