Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

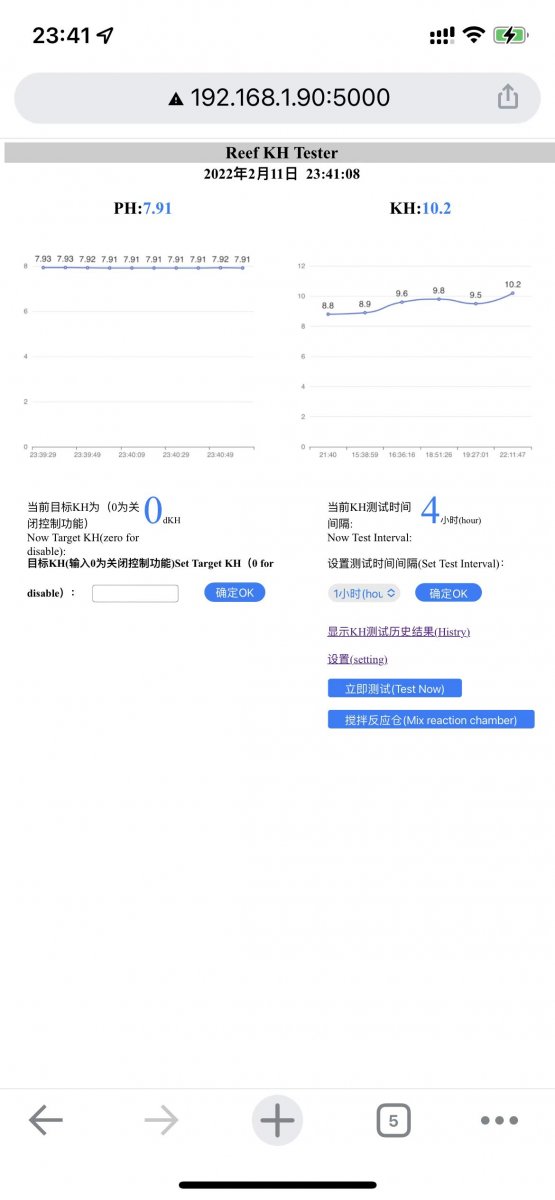

homemade automatic KH Tester With Opensource.

- Thread starter axlzys

- Start date

- Tagged users None

Hi Axlzys. I cannot log into the software. I have completed to installation. I can see the rasberry pi on my network with the correct ip address (192.168.1.90). When I type the ip address is does not work.

What am I doing wrong?

Thanks,

Dilshan

What am I doing wrong?

Thanks,

Dilshan

Hi Chris,

I did update the wpa-supplicant file. I can see it on the router with the right ip address. I am also accessing it with my computer ip being 192.168.1.x. It does not load the homepage. I think I will try re-wiring it again because apprently it does not work if it is not wired correctly, although I can see the LED is illuminated on the pH circuit board. The trials and tribullations of DIY . I will let you know if I get it working.

. I will let you know if I get it working.

I did update the wpa-supplicant file. I can see it on the router with the right ip address. I am also accessing it with my computer ip being 192.168.1.x. It does not load the homepage. I think I will try re-wiring it again because apprently it does not work if it is not wired correctly, although I can see the LED is illuminated on the pH circuit board. The trials and tribullations of DIY

can you try to use Port 5000 ? 192.168.1.x:5000Hi Chris,

I did update the wpa-supplicant file. I can see it on the router with the right ip address. I am also accessing it with my computer ip being 192.168.1.x. It does not load the homepage. I think I will try re-wiring it again because apprently it does not work if it is not wired correctly, although I can see the LED is illuminated on the pH circuit board. The trials and tribullations of DIY. I will let you know if I get it working.

or try to telnet port 5000 / ssh to 192.168.1.x

Although I have successfully implemented this meter, I have been too busy so I only responded today.

First of all, I must say thank you very much to the author axlzys, the project is great and your efforts are truly valuable.

I followed your project and to be successful, it took me months to edit and find solutions to the errors I encountered. Now I want to present the errors I encountered as well as the solutions so that others in the future can refer to them.

1. Although they are all 32GB microSD cards, there are actually slight differences between brands, so sometimes after cloning the IMG file, it will not work. I had this happen and had to switch to a 64GB card. Raspberry Pi 3 or 3+ works fine, but my Raspberry Pi 4 cannot, even though I check the router connection, I cannot access the configuration web. So I use Raspberry Pi 3 for cheap.

2. The author said the KH pump code is faulty, so the KH compensation pump feature does not work. I don't know anything about coding so I decided to remove this pump and use the voltage of this motor for the acid pump motor.

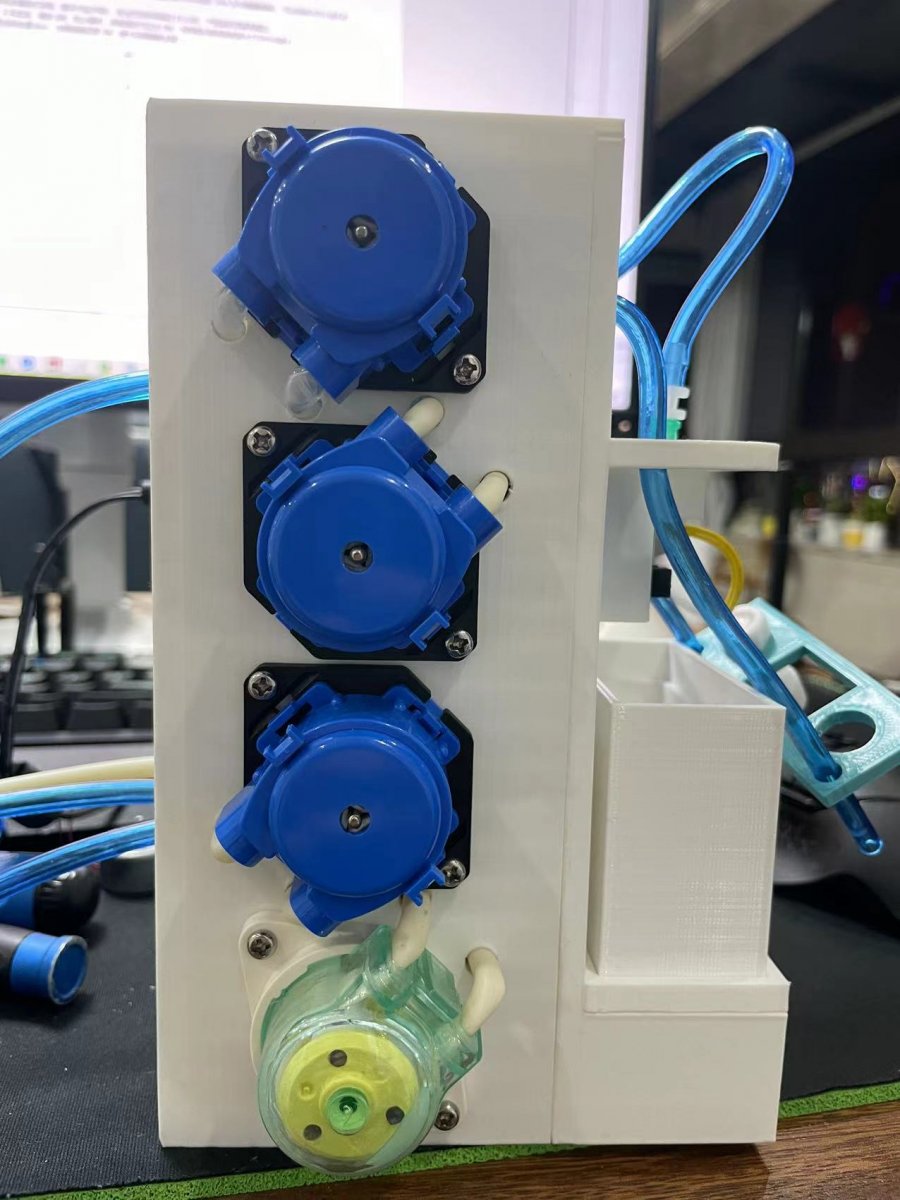

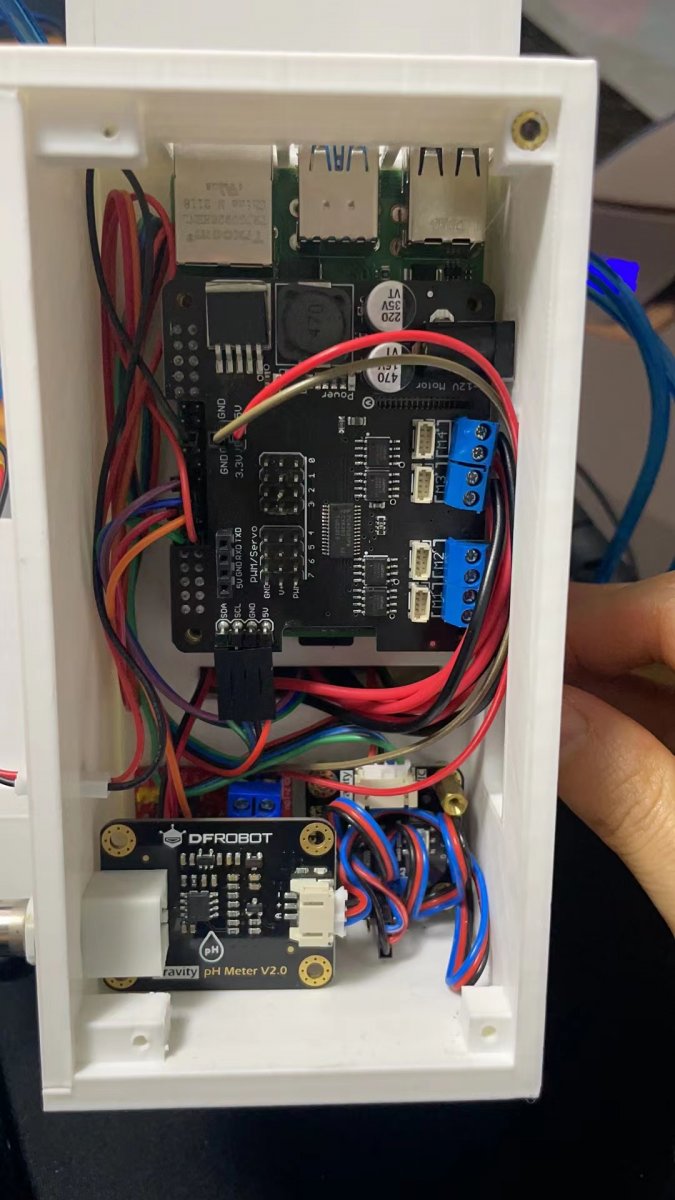

3. The acid pump gives an unstable voltage, especially when the stirring motor is turned on, so sometimes the acid pump will not run or run unstable. In addition, because the DC pump rotates quite fast, the volume of 100 drops of acid is not stable, sometimes a little bit splashes out, sometimes a whole stream of spray. I decided to use this unstable current to supply the stirring motor. I took the KH pump voltage that I removed above and supplied it to the TB6600 stepper motor driver, added the MKS OSC V1.0 pulse chopper circuit as shown and switched to using the Nema 17 stepper motor. Although I don't know anything about coding, with the TB6600 and the MKS circuit, I can change the rotation direction and the acid pump speed from fast to super slow very easily, and I will always get the exact volume of 100 drops of acid.

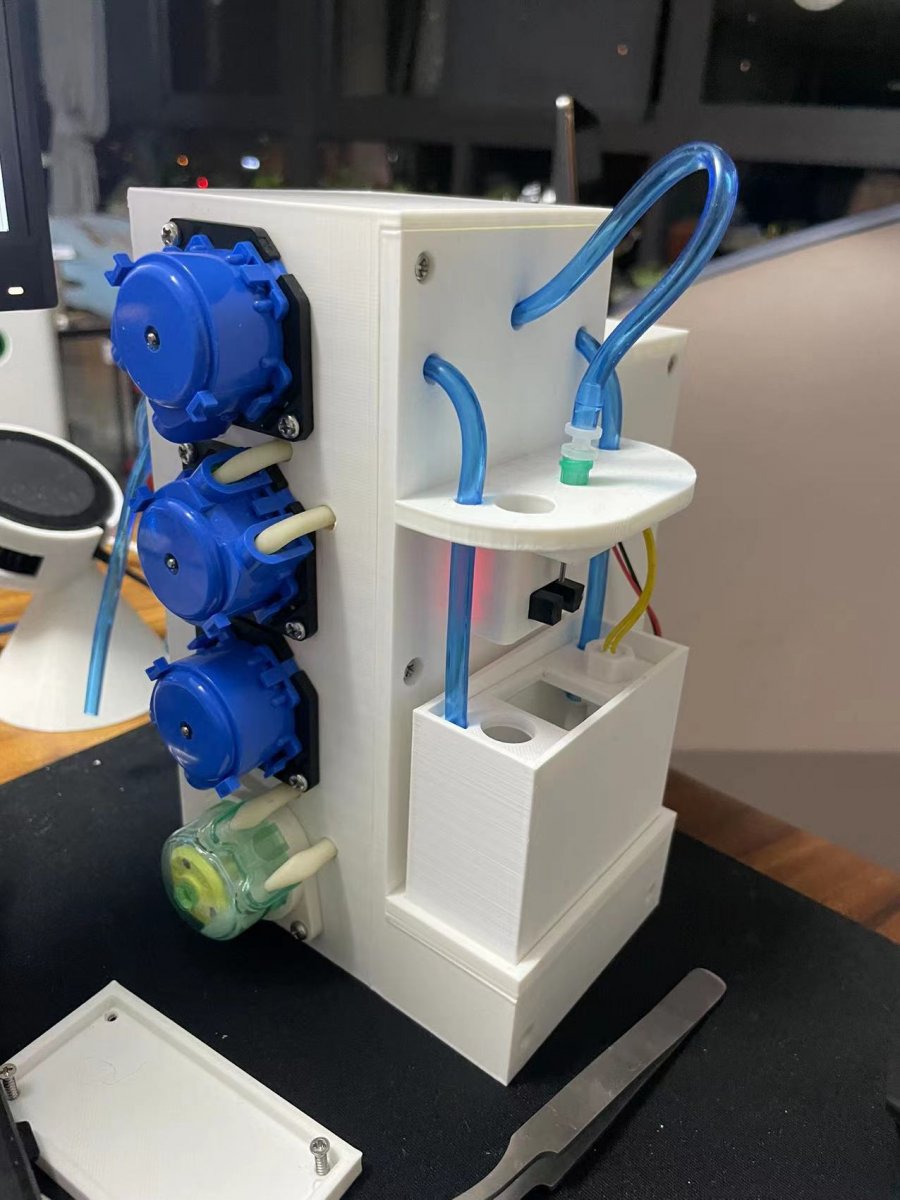

4. The stirring motor rotates too fast, causing the stirrer to often bounce. I had to edit the stl file for a larger stirring chamber (from 50ml to about 70ml), I also removed the stirring motor as well as the 3.3V/5V supply circuit. I took the unstable voltage from the acid pump, supplied the step-down circuit from 12V to about 8V, supplied the 12V cooling fan (size 40x40x20mm that I cut off the frame to leave only the motor), with 8V, the motor worked perfectly, rotated moderately and silently. When increasing the volume of the stirring chamber, it is necessary to adjust in the code the waiting time for the chamber to be full or the emptying time from 90 seconds to about 140 seconds or more, otherwise the error will not be tested because the circuit will disconnect before the chamber is full, activating the electric float. The codes of the motors also need to be adjusted or removed from the code.

5. For accurate measurement, it is necessary to satisfy:

a. The HCl acid solution must have the correct concentration of 0.1M. Where I live (Vietnam), 1 liter of 1M and 0.1M HCl acid costs the same, about 12USD, I choose to buy the 1M type, take 450ml of RO water and add 50ml of 1M acid to get 0.1M. For the most accurate, I use a Hanna pH meter (calibrated) to check my solution again, I can add RO water or acid to make sure the pH of the solution is 1.

b. I adjusted the stepper motor circuit to run very slowly for 100 drops of acid, do it 3 times. Measure the volume with a 1ml syringe (with 100 lines). My 100 drops are only 1.22ml. About the needle, I don't use metal, I'm a pediatrician so I have a lot of needles for patients, it has a metal barrel but a plastic shell on the outside, this shell is equivalent to 24G, very very small so it's great to use.

c. I don't check the chamber volume with a scale or a syringe. I plugged the pH electrode, stirrer, and silicone tubes into the correct position close to the bottom, let the IN pump run until the float activates, then use the OUT pump to run back to the measuring cup outside until there is nothing left. Do this several times to get the most accurate ml number. With all my efforts, I can now measure accurately with a deviation of only 0.1-0.2dKH compared to Hanna.

6. Since I don't know Chinese, I also changed the web interface to English for ease of use.

7. I also edited the code to remove the process of pumping out and refilling the tank after each test because it's just a waste of tank water, plus it's better to do this so the electrode will be stored in a chamber with a pH of about 4.5.

8. I also 3D printed the parts in multiple colors to make it look more fun

First of all, I must say thank you very much to the author axlzys, the project is great and your efforts are truly valuable.

I followed your project and to be successful, it took me months to edit and find solutions to the errors I encountered. Now I want to present the errors I encountered as well as the solutions so that others in the future can refer to them.

1. Although they are all 32GB microSD cards, there are actually slight differences between brands, so sometimes after cloning the IMG file, it will not work. I had this happen and had to switch to a 64GB card. Raspberry Pi 3 or 3+ works fine, but my Raspberry Pi 4 cannot, even though I check the router connection, I cannot access the configuration web. So I use Raspberry Pi 3 for cheap.

2. The author said the KH pump code is faulty, so the KH compensation pump feature does not work. I don't know anything about coding so I decided to remove this pump and use the voltage of this motor for the acid pump motor.

3. The acid pump gives an unstable voltage, especially when the stirring motor is turned on, so sometimes the acid pump will not run or run unstable. In addition, because the DC pump rotates quite fast, the volume of 100 drops of acid is not stable, sometimes a little bit splashes out, sometimes a whole stream of spray. I decided to use this unstable current to supply the stirring motor. I took the KH pump voltage that I removed above and supplied it to the TB6600 stepper motor driver, added the MKS OSC V1.0 pulse chopper circuit as shown and switched to using the Nema 17 stepper motor. Although I don't know anything about coding, with the TB6600 and the MKS circuit, I can change the rotation direction and the acid pump speed from fast to super slow very easily, and I will always get the exact volume of 100 drops of acid.

4. The stirring motor rotates too fast, causing the stirrer to often bounce. I had to edit the stl file for a larger stirring chamber (from 50ml to about 70ml), I also removed the stirring motor as well as the 3.3V/5V supply circuit. I took the unstable voltage from the acid pump, supplied the step-down circuit from 12V to about 8V, supplied the 12V cooling fan (size 40x40x20mm that I cut off the frame to leave only the motor), with 8V, the motor worked perfectly, rotated moderately and silently. When increasing the volume of the stirring chamber, it is necessary to adjust in the code the waiting time for the chamber to be full or the emptying time from 90 seconds to about 140 seconds or more, otherwise the error will not be tested because the circuit will disconnect before the chamber is full, activating the electric float. The codes of the motors also need to be adjusted or removed from the code.

5. For accurate measurement, it is necessary to satisfy:

a. The HCl acid solution must have the correct concentration of 0.1M. Where I live (Vietnam), 1 liter of 1M and 0.1M HCl acid costs the same, about 12USD, I choose to buy the 1M type, take 450ml of RO water and add 50ml of 1M acid to get 0.1M. For the most accurate, I use a Hanna pH meter (calibrated) to check my solution again, I can add RO water or acid to make sure the pH of the solution is 1.

b. I adjusted the stepper motor circuit to run very slowly for 100 drops of acid, do it 3 times. Measure the volume with a 1ml syringe (with 100 lines). My 100 drops are only 1.22ml. About the needle, I don't use metal, I'm a pediatrician so I have a lot of needles for patients, it has a metal barrel but a plastic shell on the outside, this shell is equivalent to 24G, very very small so it's great to use.

c. I don't check the chamber volume with a scale or a syringe. I plugged the pH electrode, stirrer, and silicone tubes into the correct position close to the bottom, let the IN pump run until the float activates, then use the OUT pump to run back to the measuring cup outside until there is nothing left. Do this several times to get the most accurate ml number. With all my efforts, I can now measure accurately with a deviation of only 0.1-0.2dKH compared to Hanna.

6. Since I don't know Chinese, I also changed the web interface to English for ease of use.

7. I also edited the code to remove the process of pumping out and refilling the tank after each test because it's just a waste of tank water, plus it's better to do this so the electrode will be stored in a chamber with a pH of about 4.5.

8. I also 3D printed the parts in multiple colors to make it look more fun

Last edited:

Hi tungvuu, Can I chat with you on Facebook? I would like you to share in your process, thanks!Although I have successfully implemented this meter, I have been too busy so I only responded today.

First of all, I must say thank you very much to the author axlzys, the project is great and your efforts are truly valuable.

I followed your project and to be successful, it took me months to edit and find solutions to the errors I encountered. Now I want to present the errors I encountered as well as the solutions so that others in the future can refer to them.

1. Although they are all 32GB microSD cards, there are actually slight differences between brands, so sometimes after cloning the IMG file, it will not work. I had this happen and had to switch to a 64GB card. Raspberry Pi 3 or 3+ works fine, but my Raspberry Pi 4 cannot, even though I check the router connection, I cannot access the configuration web. So I use Raspberry Pi 3 for cheap.

2. The author said the KH pump code is faulty, so the KH compensation pump feature does not work. I don't know anything about coding so I decided to remove this pump and use the voltage of this motor for the acid pump motor.

3. The acid pump gives an unstable voltage, especially when the stirring motor is turned on, so sometimes the acid pump will not run or run unstable. In addition, because the DC pump rotates quite fast, the volume of 100 drops of acid is not stable, sometimes a little bit splashes out, sometimes a whole stream of spray. I decided to use this unstable current to supply the stirring motor. I took the KH pump voltage that I removed above and supplied it to the TB6600 stepper motor driver, added the MKS OSC V1.0 pulse chopper circuit as shown and switched to using the Nema 17 stepper motor. Although I don't know anything about coding, with the TB6600 and the MKS circuit, I can change the rotation direction and the acid pump speed from fast to super slow very easily, and I will always get the exact volume of 100 drops of acid.

4. The stirring motor rotates too fast, causing the stirrer to often bounce. I had to edit the stl file for a larger stirring chamber (from 50ml to about 70ml), I also removed the stirring motor as well as the 3.3V/5V supply circuit. I took the unstable voltage from the acid pump, supplied the step-down circuit from 12V to about 8V, supplied the 12V cooling fan (size 40x40x20mm that I cut off the frame to leave only the motor), with 8V, the motor worked perfectly, rotated moderately and silently. When increasing the volume of the stirring chamber, it is necessary to adjust in the code the waiting time for the chamber to be full or the emptying time from 90 seconds to about 140 seconds or more, otherwise the error will not be tested because the circuit will disconnect before the chamber is full, activating the electric float. The codes of the motors also need to be adjusted or removed from the code.

5. For accurate measurement, it is necessary to satisfy:

a. The HCl acid solution must have the correct concentration of 0.1M. Where I live (Vietnam), 1 liter of 1M and 0.1M HCl acid costs the same, about 12USD, I choose to buy the 1M type, take 450ml of RO water and add 50ml of 1M acid to get 0.1M. For the most accurate, I use a Hanna pH meter (calibrated) to check my solution again, I can add RO water or acid to make sure the pH of the solution is 1.

b. I adjusted the stepper motor circuit to run very slowly for 100 drops of acid, do it 3 times. Measure the volume with a 1ml syringe (with 100 lines). My 100 drops are only 1.22ml. About the needle, I don't use metal, I'm a pediatrician so I have a lot of needles for patients, it has a metal barrel but a plastic shell on the outside, this shell is equivalent to 24G, very very small so it's great to use.

c. I don't check the chamber volume with a scale or a syringe. I plugged the pH electrode, stirrer, and silicone tubes into the correct position close to the bottom, let the IN pump run until the float activates, then use the OUT pump to run back to the measuring cup outside until there is nothing left. Do this several times to get the most accurate ml number. With all my efforts, I can now measure accurately with a deviation of only 0.1-0.2dKH compared to Hanna.

6. Since I don't know Chinese, I also changed the web interface to English for ease of use.

7. I also edited the code to remove the process of pumping out and refilling the tank after each test because it's just a waste of tank water, plus it's better to do this so the electrode will be stored in a chamber with a pH of about 4.5.

8. I also 3D printed the parts in multiple colors to make it look more fun

did you change the code for using Stepper motor? instead of two DC motors you can use a Stepper motor and there should not be any issue regarding voltage. (from where did you buy the stepper pump? any link?)Although I have successfully implemented this meter, I have been too busy so I only responded today.

First of all, I must say thank you very much to the author axlzys, the project is great and your efforts are truly valuable.

I followed your project and to be successful, it took me months to edit and find solutions to the errors I encountered. Now I want to present the errors I encountered as well as the solutions so that others in the future can refer to them.

1. Although they are all 32GB microSD cards, there are actually slight differences between brands, so sometimes after cloning the IMG file, it will not work. I had this happen and had to switch to a 64GB card. Raspberry Pi 3 or 3+ works fine, but my Raspberry Pi 4 cannot, even though I check the router connection, I cannot access the configuration web. So I use Raspberry Pi 3 for cheap.

2. The author said the KH pump code is faulty, so the KH compensation pump feature does not work. I don't know anything about coding so I decided to remove this pump and use the voltage of this motor for the acid pump motor.

3. The acid pump gives an unstable voltage, especially when the stirring motor is turned on, so sometimes the acid pump will not run or run unstable. In addition, because the DC pump rotates quite fast, the volume of 100 drops of acid is not stable, sometimes a little bit splashes out, sometimes a whole stream of spray. I decided to use this unstable current to supply the stirring motor. I took the KH pump voltage that I removed above and supplied it to the TB6600 stepper motor driver, added the MKS OSC V1.0 pulse chopper circuit as shown and switched to using the Nema 17 stepper motor. Although I don't know anything about coding, with the TB6600 and the MKS circuit, I can change the rotation direction and the acid pump speed from fast to super slow very easily, and I will always get the exact volume of 100 drops of acid.

4. The stirring motor rotates too fast, causing the stirrer to often bounce. I had to edit the stl file for a larger stirring chamber (from 50ml to about 70ml), I also removed the stirring motor as well as the 3.3V/5V supply circuit. I took the unstable voltage from the acid pump, supplied the step-down circuit from 12V to about 8V, supplied the 12V cooling fan (size 40x40x20mm that I cut off the frame to leave only the motor), with 8V, the motor worked perfectly, rotated moderately and silently. When increasing the volume of the stirring chamber, it is necessary to adjust in the code the waiting time for the chamber to be full or the emptying time from 90 seconds to about 140 seconds or more, otherwise the error will not be tested because the circuit will disconnect before the chamber is full, activating the electric float. The codes of the motors also need to be adjusted or removed from the code.

5. For accurate measurement, it is necessary to satisfy:

a. The HCl acid solution must have the correct concentration of 0.1M. Where I live (Vietnam), 1 liter of 1M and 0.1M HCl acid costs the same, about 12USD, I choose to buy the 1M type, take 450ml of RO water and add 50ml of 1M acid to get 0.1M. For the most accurate, I use a Hanna pH meter (calibrated) to check my solution again, I can add RO water or acid to make sure the pH of the solution is 1.

b. I adjusted the stepper motor circuit to run very slowly for 100 drops of acid, do it 3 times. Measure the volume with a 1ml syringe (with 100 lines). My 100 drops are only 1.22ml. About the needle, I don't use metal, I'm a pediatrician so I have a lot of needles for patients, it has a metal barrel but a plastic shell on the outside, this shell is equivalent to 24G, very very small so it's great to use.

c. I don't check the chamber volume with a scale or a syringe. I plugged the pH electrode, stirrer, and silicone tubes into the correct position close to the bottom, let the IN pump run until the float activates, then use the OUT pump to run back to the measuring cup outside until there is nothing left. Do this several times to get the most accurate ml number. With all my efforts, I can now measure accurately with a deviation of only 0.1-0.2dKH compared to Hanna.

6. Since I don't know Chinese, I also changed the web interface to English for ease of use.

7. I also edited the code to remove the process of pumping out and refilling the tank after each test because it's just a waste of tank water, plus it's better to do this so the electrode will be stored in a chamber with a pH of about 4.5.

8. I also 3D printed the parts in multiple colors to make it look more fun

also can you explain about the needle you used? i think it is simillar to the photo I attached but it has some extra parts.

Thanks

@tosla As I said, I don't know anything about coding so I can't edit code compatible with stepper motors.

So to be able to use stepper motors, I have to go through the TB6600 driver circuit and the MKS circuit.

According to the author's diagram, I kept the IN and OUT pumps, the acid pump has an unstable voltage when the stirring motor is working, so I removed the 5V/3V line, took 12V from the acid pump and fed it through the LM2596 step-down circuit to 8V to supply a 12V cooling fan (the motor retention frame was cut off, and a magnet was glued to make a stirring motor). The voltage from the KH pump was removed, I supplied it to TB6600 and MKS, at this time the stepper motor control is completely handled by TB6600 and MKS, it is no longer related to the code, so I deleted it in the code. I printed a box for TB6600 and MKS, connect to body with 2 scews, you can see a green box on top of my machine I posted. You can see the wiring method I posted above or there are many on youtube. The stepper motor is Nema 17, just buy an additional Dosing head.

Amazon product

As for the needle used, you can watch this video, mine is exactly the same but smaller, size 24G, just remove the metal core and keep the plastic part outside

So to be able to use stepper motors, I have to go through the TB6600 driver circuit and the MKS circuit.

According to the author's diagram, I kept the IN and OUT pumps, the acid pump has an unstable voltage when the stirring motor is working, so I removed the 5V/3V line, took 12V from the acid pump and fed it through the LM2596 step-down circuit to 8V to supply a 12V cooling fan (the motor retention frame was cut off, and a magnet was glued to make a stirring motor). The voltage from the KH pump was removed, I supplied it to TB6600 and MKS, at this time the stepper motor control is completely handled by TB6600 and MKS, it is no longer related to the code, so I deleted it in the code. I printed a box for TB6600 and MKS, connect to body with 2 scews, you can see a green box on top of my machine I posted. You can see the wiring method I posted above or there are many on youtube. The stepper motor is Nema 17, just buy an additional Dosing head.

Amazon product

As for the needle used, you can watch this video, mine is exactly the same but smaller, size 24G, just remove the metal core and keep the plastic part outside

did you change the code for using Stepper motor? instead of two DC motors you can use a Stepper motor and there should not be any issue regarding voltage. (from where did you buy the stepper pump? any link?)

also can you explain about the needle you used? i think it is simillar to the photo I attached but it has some extra parts.

Thanks

Last edited:

I am very busy because I work in the ICU of the hospital, I also rarely go on Facebook, probably because of the time difference with you. So if you need anything, just email me [email protected], I would be very happy if I could help youHi tungvuu, Can I chat with you on Facebook? I would like you to share in your process, thanks!

Hello, I’m also from Vietnam, currently in Hanoi. I’m planning to work on this project soon, and I’d greatly appreciate your support. Thank you!I am very busy because I work in the ICU of the hospital, I also rarely go on Facebook, probably because of the time difference with you. So if you need anything, just email me [email protected], I would be very happy if I could help you

You’ll need a bit of programming knowledge—are you ready to learn? I plan to port the project’s code to the ESP8266 module soon, which will make uploading the code easier. However, it probably won’t be ready until mid-next year.can anyone telll me how to upload code to rasberry pi, did not understand the github page

ok thanks, the new tank will come by mid next year so im fineYou’ll need a bit of programming knowledge—are you ready to learn? I plan to port the project’s code to the ESP8266 module soon, which will make uploading the code easier. However, it probably won’t be ready until mid-next year.

- Joined

- Aug 14, 2019

- Messages

- 21

- Reaction score

- 5

yeaaaah would love to try it out but its asking for location and credit card details ..... seems a bit scetchhello everyone,

I made a KH tester machine at home.Control with Raspberry Pi.

For the benefit of aquarists around the world, I decided to open source it.

I upload all details to the github.com, here it is : https://github.com/axlzys/KH-Tester

The case made by 3D Print,

The print time of main body and front cover are more than 10 hours, you may need a encloses naturally 3D printer.

About test accuracy:The test accuracy is 0.1dkh,and with 2 month tested,it has 0.1-0.3 difference from Hanna.

If you have any questions. Please tell me.

Here is some pics of this DIY

What's asking for your credit card? github?yeaaaah would love to try it out but its asking for location and credit card details ..... seems a bit scetch

Traceback (most recent call last):

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 172, in __probe_for_device

self.i2c.writeto(self.device_address, b"")

File "/home/pi/.local/lib/python3.7/site-packages/busio.py", line 215, in writeto

return self._i2c.writeto(address, buffer, stop=True)

File "/home/pi/.local/lib/python3.7/site-packages/adafruit_blinka/microcontroller/generic_linux/i2c.py", line 60, in writeto

self._i2c_bus.write_bytes(address, buffer[start:end])

File "/usr/local/lib/python3.7/dist-packages/Adafruit_PureIO/smbus.py", line 314, in write_bytes

self._device.write(buf)

OSError: [Errno 121] Remote I/O error

During handling of the above exception, another exception occurred:

Traceback (most recent call last):

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 178, in __probe_for_device

self.i2c.readfrom_into(self.device_address, result)

File "/home/pi/.local/lib/python3.7/site-packages/busio.py", line 205, in readfrom_into

return self._i2c.readfrom_into(address, buffer, stop=True)

File "/home/pi/.local/lib/python3.7/site-packages/adafruit_blinka/microcontroller/generic_linux/i2c.py", line 67, in readfrom_into

readin = self._i2c_bus.read_bytes(address, end - start)

File "/usr/local/lib/python3.7/dist-packages/Adafruit_PureIO/smbus.py", line 181, in read_bytes

return self._device.read(number)

OSError: [Errno 121] Remote I/O error

During handling of the above exception, another exception occurred:

Traceback (most recent call last):

File "main.py", line 22, in <module>

from Tester import tester

File "/home/pi/APP/examples/examples/Tester.py", line 40, in <module>

kit = MotorKit(i2c=board.I2C())

File "/home/pi/APP/examples/examples/adafruit_motorkit.py", line 80, in __init__

self._pca = PCA9685(i2c, address=address)

File "/home/pi/APP/examples/examples/adafruit_pca9685.py", line 137, in __init__

self.i2c_device = i2c_device.I2CDevice(i2c_bus, address)

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 68, in __init__

self.__probe_for_device()

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 181, in __probe_for_device

raise ValueError("No I2C device at address: 0x%x" % self.device_address)

ValueError: No I2C device at address: 0x60

-------------------------------------------------------------

After boot up I check aaa.services status and it failed to run. I execute main.py and the error code was show up. Anyone know how to fix this?

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 172, in __probe_for_device

self.i2c.writeto(self.device_address, b"")

File "/home/pi/.local/lib/python3.7/site-packages/busio.py", line 215, in writeto

return self._i2c.writeto(address, buffer, stop=True)

File "/home/pi/.local/lib/python3.7/site-packages/adafruit_blinka/microcontroller/generic_linux/i2c.py", line 60, in writeto

self._i2c_bus.write_bytes(address, buffer[start:end])

File "/usr/local/lib/python3.7/dist-packages/Adafruit_PureIO/smbus.py", line 314, in write_bytes

self._device.write(buf)

OSError: [Errno 121] Remote I/O error

During handling of the above exception, another exception occurred:

Traceback (most recent call last):

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 178, in __probe_for_device

self.i2c.readfrom_into(self.device_address, result)

File "/home/pi/.local/lib/python3.7/site-packages/busio.py", line 205, in readfrom_into

return self._i2c.readfrom_into(address, buffer, stop=True)

File "/home/pi/.local/lib/python3.7/site-packages/adafruit_blinka/microcontroller/generic_linux/i2c.py", line 67, in readfrom_into

readin = self._i2c_bus.read_bytes(address, end - start)

File "/usr/local/lib/python3.7/dist-packages/Adafruit_PureIO/smbus.py", line 181, in read_bytes

return self._device.read(number)

OSError: [Errno 121] Remote I/O error

During handling of the above exception, another exception occurred:

Traceback (most recent call last):

File "main.py", line 22, in <module>

from Tester import tester

File "/home/pi/APP/examples/examples/Tester.py", line 40, in <module>

kit = MotorKit(i2c=board.I2C())

File "/home/pi/APP/examples/examples/adafruit_motorkit.py", line 80, in __init__

self._pca = PCA9685(i2c, address=address)

File "/home/pi/APP/examples/examples/adafruit_pca9685.py", line 137, in __init__

self.i2c_device = i2c_device.I2CDevice(i2c_bus, address)

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 68, in __init__

self.__probe_for_device()

File "/home/pi/APP/examples/examples/adafruit_bus_device/i2c_device.py", line 181, in __probe_for_device

raise ValueError("No I2C device at address: 0x%x" % self.device_address)

ValueError: No I2C device at address: 0x60

-------------------------------------------------------------

After boot up I check aaa.services status and it failed to run. I execute main.py and the error code was show up. Anyone know how to fix this?

Similar threads

- Price: 550

- Shipping Available

- Replies

- 1

- Views

- 648

TOP 10 Trending Threads

- Replies

- 28

- Views

- 341

- Replies

- 91

- Views

- 1,232

- Replies

- 172

- Views

- 1,163

- Replies

- 20

- Views

- 213

- Replies

- 32

- Views

- 259

- Replies

- 23

- Views

- 279