I’ve done numerous tests myself with solvent and 40/42… I’ve found personally that nothing is stronger than a solvent weld honestly no matter what that paper says from Weld-On… you can try this yourself.. glue up 2 pieces at a 90* angle and let them set for a couple days.. flip over on the ground so it’s like a teepee and smash it with a sledge hammer… solvent will break the plastic and the weld is left in full tact… 40/42 is comparable no doubt but much more material is left with solvent vs adhesive glues… now if you bake the 40-42 properly it gives the same affects as solvent welding..Thanks for posting their thoughts. Without seeing some lab work shoing there's no difference in strength I'd stick with Weldon's published data. That being said when I first started working with #40 I tried breaking joints. Properly prepped joints glued with either #3 or #40 had acrylic breaking before the joint broke.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic Thickness 30” tall

- Thread starter piranhaman00

- Start date

- Tagged users None

. . . when I first started working with #40 I tried breaking joints. Properly prepped joints glued with either #3 or #40 had acrylic breaking before the joint broke.

… you can try this yourself.. glue up 2 pieces at a 90* angle and let them set for a couple days..

I did, well, I used a 60# piece of railroad track, not a sledge hammer. Maybe that's the difference in results.

I’ll run the next one over with a fork lift or my 20 ton crane haha!I did, well, I used a 60# piece of railroad track, not a sledge hammer. Maybe that's the difference in results.

Same experience here with 40 and 42 as well as 3. Mix my own solvent after discussing with plastic engineer years ago.Thanks for posting their thoughts. Without seeing some lab work shoing there's no difference in strength I'd stick with Weldon's published data. That being said when I first started working with #40 I tried breaking joints. Properly prepped joints glued with either #3 or #40 had acrylic breaking before the joint broke.

Of what? Lol.. this thread is derailed! HahahahahaI want to see more pictures!

I’ll run the next one over with a fork lift or my 20 ton crane haha!

Now you're just bragging!

James explains this as well in a way that makes a lot of sense. You can't just look at the numbers that the manufacturers provide with respect to this issue. It's more than that.Same experience here with 40 and 42 as well as 3. Mix my own solvent after discussing with plastic engineer years ago.

So, from James:

Quote from email posted with permission, additionally

Go to about the 7:15 mark in the video. That's I believe 2" acrylic

He also included a few other pics of tanks he's built

Meh, this is why I walked away from the world..

Yes, you can solvent glue whatever thickness you want. The theoretical limitations are tooling, material chemistry, and really - how far you can get the solvent to flow well. The practical limit is 1.5"-2" for a variety of reasons. The main reason is tooling as cutter flex becomes problematic. Another is the material availability; not many companies left that make large sheets suitable. The only good one left is Polycast and their limits become my limits. Getting solvent to flow well gets harder and harder past that 2" range - imagine trying to "push" a bubble in a 4" joint.. rather tough. You really can't shim effectively and clamping much can bring other issues.

On strength; it's only theoretical. 40/42 still has to "bite" into material and this bite varies with acrylic chemistry, edge prep, etc.

https://www.opb.org/article/2021/02/05/sea-jellies-jellyfish-oregon-coast-aquarium/

The above is a 6×10' tank I did in '97 and has been in continuous operation to this day. All solvent. This photo has been published so I don't mind it being online, I included a coupla others that are common enough.

I guess I make unicorns for a living

James

Quote from email posted with permission, additionally

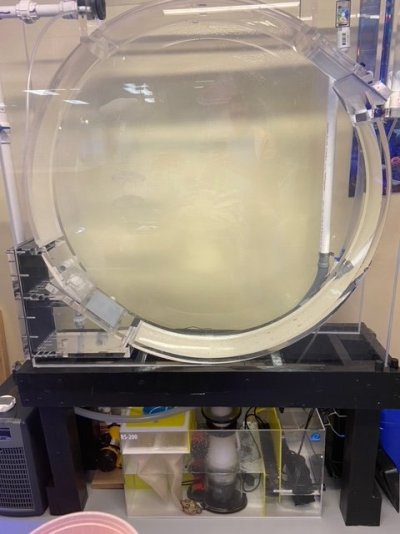

No problem.. only thing I’d add was that drop tank was 1.25" acrylic on the verticals and 1" top and bottoms. 90" long and 48" tall... if you post those.

Even the little kreisel pic I sent was 48" tall

Go to about the 7:15 mark in the video. That's I believe 2" acrylic

He also included a few other pics of tanks he's built

Attachments

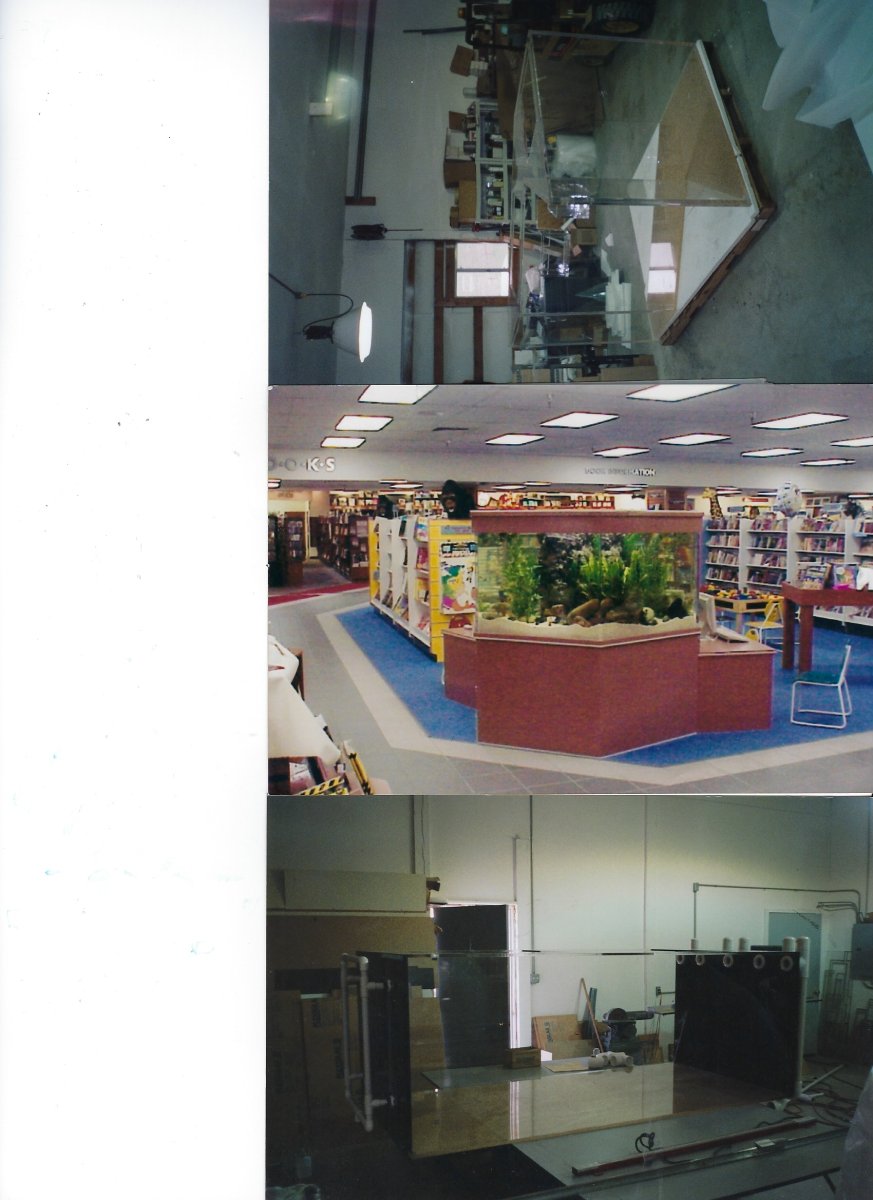

Top picture is 1 1/2" with picture sideways delivered to Guam public aquarium. 42 and Solvent weld. 7 sides.

2nd picture with Corian stand and table is 1" Hexagon 72" on the points (used Weldon 42 to control seams)

3rd picture is 96" x 48" x 30" all 1" solvent weld. In the Stanley Hotel (where they filmed The Shining)

4 picture Guam aquarium with proper orientation. Combination of 42 and solvent welds due to angles.

5 One of two aquariums 16' x 3' x 4' tall all 2" with butt seam in middle of 2-inch panels. 1 1/2" tops and bottoms shown during required static load test. All solvent welds all seams including the butt seam. 8' table in from for scale.

6 48" x 48" x 30" all 1" solvent welds all seams with custom Corian base and top skirt. I was in the process of repo of the set up due to bounced checks from the buyer LOL. They finally paid off and kept the tank.

Just a few old Unicorns before digital photos.

Backyard Cowboy.

Last edited:

How did you butt seam with solvent?

Top picture is 1 1/2" with picture sideways delivered to Guam public aquarium. 42 and Solvent weld. 7 sides.

2nd picture with Corian stand and table is 1" Hexagon 72" on the points (used Weldon 42 to control seams)

3rd picture is 96" x 48" x 30" all 1" solvent weld. In the Stanley Hotel (where they filmed The Shining)

4 picture Guam aquarium with proper orientation. Combination of 42 and solvent welds due to angles.

5 One of two aquariums 16' x 3' x 4' tall all 2" with butt seam in middle of 2-inch panels. 1 1/2" tops and bottoms shown during required static load test. All solvent welds all seams including the butt seam. 8' table in from for scale.

6 48" x 48" x 30" all 1" solvent welds all seams with custom Corian base and top skirt. I was in the process of repo of the set up due to bounced checks from the buyer LOL. They finally paid off and kept the tank.

Just a few old Unicorns before digital photos.

Backyard Cowboy.

That is a trick. Send me a check and I'll give you the trick LOL! Laird Plastics requested a white paper and I respectfully declined. Tell you what I will trade for the compression bits you use that polish the edge as you hand router the tanks after assembly. PM me and we can get the details going. Have a great day!How did you butt seam with solvent?

Backyard Cowboy.

Giddyup! The only way I can see that happening is using polyester tape. Nice work.That is a trick. Send me a check and I'll give you the trick LOL! Laird Plastics requested a white paper and I respectfully declined. Tell you what I will trade for the compression bits you use that polish the edge as you hand router the tanks after assembly. PM me and we can get the details going. Have a great day!

Backyard Cowboy.

Will the panels on stands be interchangeable?Did you get a chance to see the new stand designs? Pretty much finalized and all we are waiting on is the equipped

Sorry. I don't follow. If you mean can you swap out one color for another then the answer is yesWill the panels on stands be interchangeable?

A swing and a miss. Happy trails to you until we meet again! LOLGiddyup! The only way I can see that happening is using polyester tape. Nice work.

Agreed when solvent welding 2" thick panels it was a two-person job. That is how we did it anyway. Three people might not be bad even. One of us ran the solvent and the other removed the pins at a certain time interval. Worked great.Of course you can solvent weld it! You can solvent weld 6” if you want it’s all acrylic.. it’s trying to get a good clean joint at that thick is very tricky.. almost impossible to get it Bubble free so we switch over to 2 part glues and centrifugal vacuums etc. I solvent weld 1” all the time with no issues for the most part.. if I’m gluing a bottom on a 4x8 tank that’s 1” thick I switch to 40-42 myself.. I’ve solvent welded a couple that size and they came out fine but had a few bubbles here or there.. almost need a second person wicking the joints if they know what they’re doing lol..

James does some great work. I think I have seen his some of his aquariums at Newport Aquarium on the Oregon coast. A very skilled fabricator to be sure! Love Polycast Acrylic but the price....just wow!So, from James:

Quote from email posted with permission, additionally

Go to about the 7:15 mark in the video. That's I believe 2" acrylic

He also included a few other pics of tanks he's built

Yes , for example, if you get blue doors and want to change to black. Or change all panels and doors to white .Sorry. I don't follow. If you mean can you swap out one color for another then the answer is yes

So 4 pages later what is the general consensus or did we all reach one? I personally tend to error on the side of overbuild for safety. I don't want 400 gallons of water raging through my house. Just like I wouldn't fly a single engine plane across the Atlantic.

Similar threads

- Replies

- 6

- Views

- 193

- Replies

- 26

- Views

- 347