Ill check this when i get home but why do i want one to have a strong flow and the other to not? Just trying to understand the reasoning lolPut your hand under the pipe that’s not causing issues. Is it a strong full siphon?

Then feel the flow under the pipe with an air valve causing noise/ bubbles. Is it also strong flow or is it barely strong enough to feel? If this pipe has strong flow, it shouldn’t and there’s your problem.

This can be fixed by a gate (or a ball) on this channel.

I’d also experiment valving down the return pump (on the output side) and trying to tune it so that you have a full siphon in pipe 1, and just a little extra flow in pipe2( the one with the air valve)

That would also potentially solve the issue.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How can i quiet a noisy overflow?

- Thread starter Bthomas

- Start date

- Tagged users None

Ah so i could angle it down with the union.. gotcha. Not sure i have room for that tho but ill seeThe problem could be that it's horizontal with no angle to it. The air is just stuck to the roof of the pipe. With an angle the air would travel upwards and out.

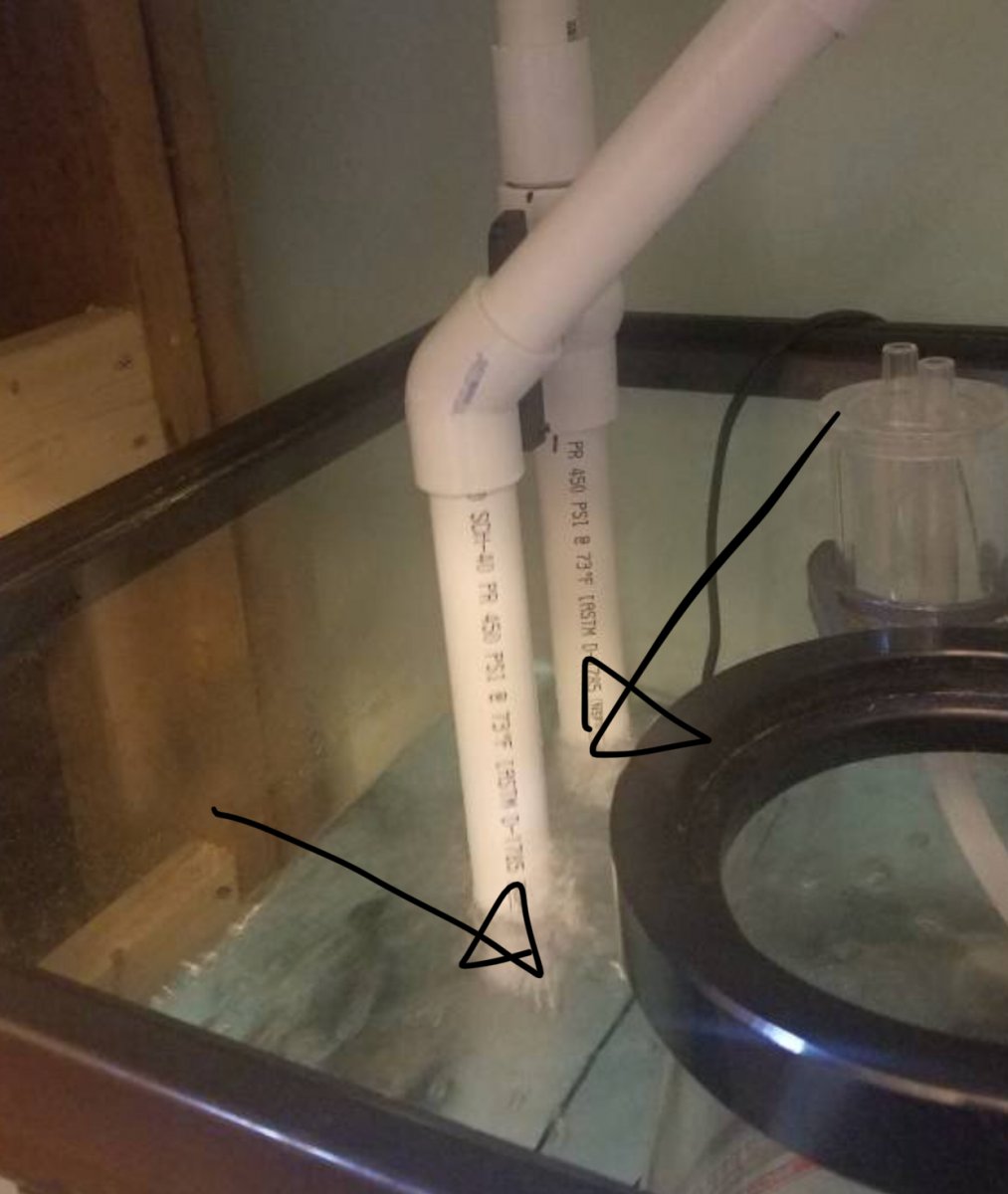

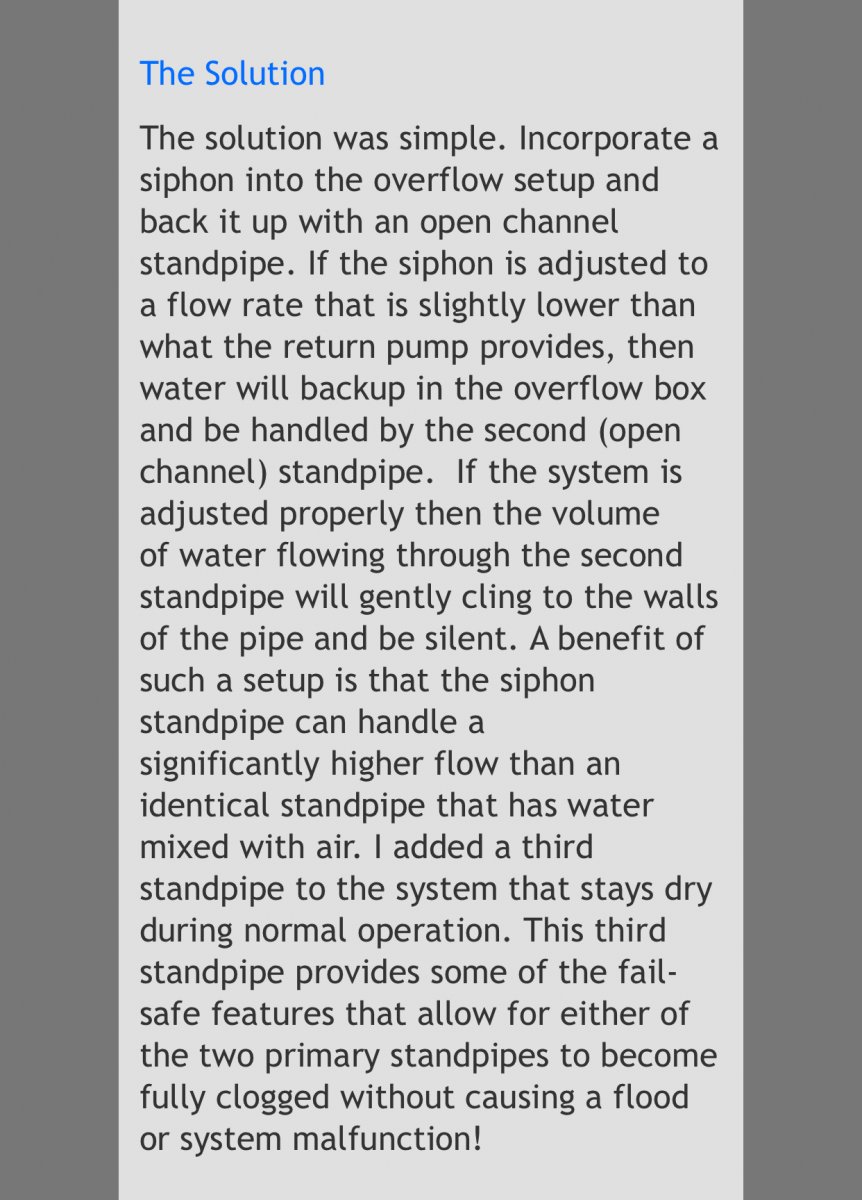

Because you’re running what is basically a Bean without the dry emergency. Unless I missed something in your photos. And for those systems to operate, your siphon handles the full load of the tank and is dead silent with any remainder flowing into the open channel. Which is what you have if you have a standpipe with an airline/ valve on it. Here’s a screenshot briefly detailing how it works.Ill check this when i get home but why do i want one to have a strong flow and the other to not? Just trying to understand the reasoning lol

Just noticed the hole on the bottom/ side of your downturned elbow. I’d remove that fitting and replace it with a new one, and ensure that the waterline comes about about an inch above the bottom of your downturned ell’s. You can adjust this by the valve on your return.

Just noticed your drains. They terminate too far into the sump. Which causes cavitation and startup issues with the siphon.

I would trim them down. Either remove the pipes and cut them, or if they’re glued( which they should be) take a hacksaw blade( without the saw) and use it to cut the bottoms of your standpipes so they terminate a half inch into the waterline. Or adjust the water level in your sump to achieve the same goal.

Can someone on here show pictures of how yours is setup. I may want to redo mine too, ha. Also pvc cutters are the best invention ever. $14 at lowes. Took me awhile to realize that, ha.

Now im confused.. im running a durso as far i know.. sorry if i sound dumb..first tank so i dont know much about thisBecause you’re running what is basically a Bean without the dry emergency. Unless I missed something in your photos. And for those systems to operate, your siphon handles the full load of the tank and is dead silent with any remainder flowing into the open channel. Which is what you have if you have a standpipe with an airline/ valve on it. Here’s a screenshot briefly detailing how it works.

Yeah I didn’t notice the vented pipe. I maintain though that your issue will be likely be solved by ditching the side-vented pipe and making it an open channel( keep the air valve in the top cap) and keep your full siphon, valve your return output appropriately and cut your standpipes shorter into the sump. That’s what I would do and I’ve plumbed probably a couple dozen similar setups. The only thing you’d be missing is the dry emergency.Now im confused.. im running a durso as far i know.. sorry if i sound dumb..first tank so i dont know much about this

I had the same issue, two things worked. 1. reduce flow, last resort due to tank turnover rate. 2. Put an air line hose down into the vent hole (may have to drill out a little to make it work) feed 18 " or so. keep it attached to the top and that stopped the insane gurgling in the tank.

Arnt those holes there as a syphon break or something tho?Yeah I didn’t notice the vented pipe. I maintain though that your issue will be likely be solved by ditching the side-vented pipe and making it an open channel( keep the air valve in the top cap) and keep your full siphon, valve your return output appropriately and cut your standpipes shorter into the sump. That’s what I would do and I’ve plumbed probably a couple dozen similar setups. The only thing you’d be missing is the dry emergency.

So u dont think putting a gate valve on the horizontal would help any now?

You have a valve on top of your cap set up for an airline in your open channel that serves that purpose. Attach an airline and bend it over so that if water rises towards the top of your tank rim, it will trigger the open channel into a full siphon. Having it higher allows you to have more flow into your box with your downturned ell’s, which allows more turnover, while still having a Siphon break.Arnt those holes there as a syphon break or something tho?

So u dont think putting a gate valve on the horizontal would help any now?

Is there any way around replacing that piece? The whole standpipe was a kit that came together and theres a strainer that fits on the bottom of that elbow. Id rather not replace that if not necessary. Not even sure i could find an elbow that fits right on thatYou have a valve on top of your cap set up for an airline in your open channel that serves that purpose. Attach an airline and bend it over so that if water rises towards the top of your tank rim, it will trigger the open channel into a full siphon. Having it higher allows you to have more flow into your box with your downturned ell’s, which allows more turnover, while still having a Siphon break.

Is there any way around replacing that piece? The whole standpipe was a kit that came together and theres a strainer that fits on the bottom of that elbow. Id rather not replace that if not necessary. Not even sure i could find an elbow that fits right on that

What’s the clearance between the bottom of your downturned elbows and the floor of your overflow? It should be about 3/4 of an inch or so.

Oh no.. the elbow with the strainer only goes a few inches. Theres at least a foot and a half or soWhat’s the clearance between the bottom of your downturned elbows and the floor of your overflow? It should be about 3/4 of an inch or so.

No: the bottoms of your downturned elbows, in your overflow box. What’s the distance between them and the floor of the overflow box.Oh no.. the elbow with the strainer only goes a few inches. Theres at least a foot and a half or so

Right.. the tank is drilled at the bottom and the elbows only go down a few inchesNo: the bottoms of your downturned elbows, in your overflow box. What’s the distance between them and the floor of the overflow box.

Copy, my bad from the photo it looked to me like it was a shallow overflow box.Right.. the tank is drilled at the bottom and the elbows only go down a few inches

In that case, try cutting the pipes or adjusting your water level in your sump when you have the chance. You already have trouble purging air thanks to that horizontal run. Sounds trivial but terminating the pipe just into the waterline usually solves this issue.

You’re aiming for half an inch into the waterline ideally. No more than an inch.

Not trying to doubt you i just dont see how that would get rid of bubbles lolCopy, my bad from the photo it looked to me like it was a shallow overflow box.

In that case, try cutting the pipes or adjusting your water level in your sump when you have the chance. You already have trouble purging air thanks to that horizontal run. Sounds trivial but terminating the pipe just into the waterline usually solves this issue.

You’re aiming for half an inch into the waterline ideally. No more than an inch.

Lol fair enough. And no problem. Google is a helpful tool.

Here’s a similar case though.

https://www.reef2reef.com/threads/help-needed-to-quiet-down-bean-animal-overflow.280258/page-2

In your case though it sounds like it’s your vented pipe causing all the noise. Without seeing your system physically it’s hard to nail it down.

But the standpipe level into the sump is basic physics. Look it up.

Id cut the pipes regardless if it were me, but if that doesn’t work, you may just have way too much flow running through the system and valving down your return will fix it, and/ or throwing a gate valve on your vented pipe. I would play with both. Sure, you’ve got a ton of turnover through both channels which is nice, but micro bubbles and noise isn’t something I’m down with personally.

To recap I’d cut the pipes in relation to the sump/waterline, id throw a quality gate on the vented pipe and I’d play with the return pump output with a valve.

Alright I’m out Dude! Gotta take the lady out tonight.

Here’s a similar case though.

https://www.reef2reef.com/threads/help-needed-to-quiet-down-bean-animal-overflow.280258/page-2

In your case though it sounds like it’s your vented pipe causing all the noise. Without seeing your system physically it’s hard to nail it down.

But the standpipe level into the sump is basic physics. Look it up.

Id cut the pipes regardless if it were me, but if that doesn’t work, you may just have way too much flow running through the system and valving down your return will fix it, and/ or throwing a gate valve on your vented pipe. I would play with both. Sure, you’ve got a ton of turnover through both channels which is nice, but micro bubbles and noise isn’t something I’m down with personally.

To recap I’d cut the pipes in relation to the sump/waterline, id throw a quality gate on the vented pipe and I’d play with the return pump output with a valve.

Alright I’m out Dude! Gotta take the lady out tonight.

Thanks alot for all your help. Ill read through that tread you linked and play around with the pipes some. I will go ahead and cut them shorter cause i know it cant get any worse lolLol fair enough. And no problem. Google is a helpful tool.

Here’s a similar case though.

https://www.reef2reef.com/threads/help-needed-to-quiet-down-bean-animal-overflow.280258/page-2

In your case though it sounds like it’s your vented pipe causing all the noise. Without seeing your system physically it’s hard to nail it down.

But the standpipe level into the sump is basic physics. Look it up.

Id cut the pipes regardless if it were me, but if that doesn’t work, you may just have way too much flow running through the system and valving down your return will fix it, and/ or throwing a gate valve on your vented pipe. I would play with both. Sure, you’ve got a ton of turnover through both channels which is nice, but micro bubbles and noise isn’t something I’m down with personally.

To recap I’d cut the pipes in relation to the sump/waterline, id throw a quality gate on the vented pipe and I’d play with the return pump output with a valve.

Alright I’m out Dude! Gotta take the lady out tonight.

One thing tho.. both the overflow pipes are vented like that at the top. Theres 2 overflow chambers like the one pictured. Its just the one with the horizontal pipe is giving me issues..

Ok so i cut the drain line to a half inch below the water line.. no change. Still bubbling like crazy.

I did notice tho that the drain line that is not bubbling has very little water flowing through it. The bubbling one has very strong flow.

I did notice tho that the drain line that is not bubbling has very little water flowing through it. The bubbling one has very strong flow.

Similar threads

- Replies

- 5

- Views

- 142

- Replies

- 6

- Views

- 133

- Replies

- 14

- Views

- 368

- Replies

- 4

- Views

- 235

- Replies

- 7

- Views

- 127