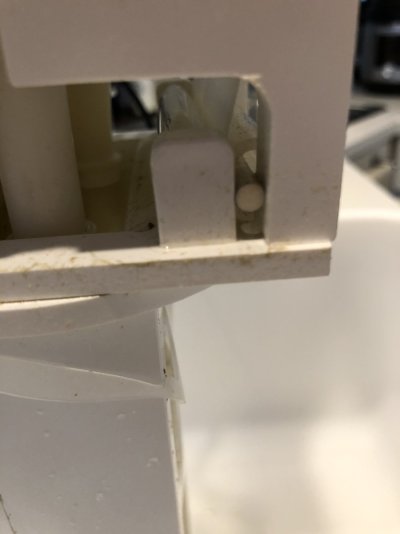

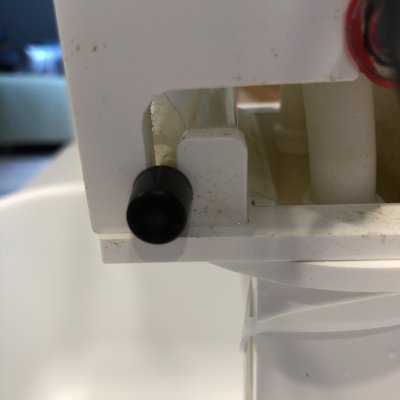

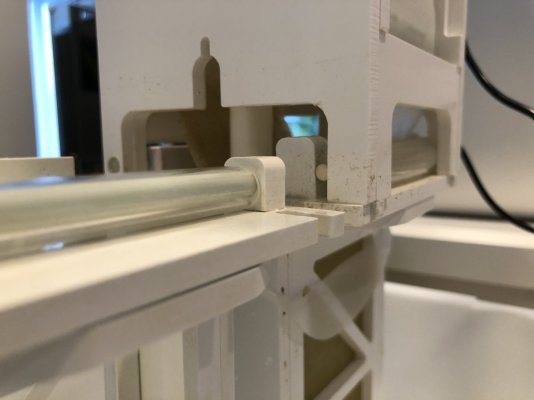

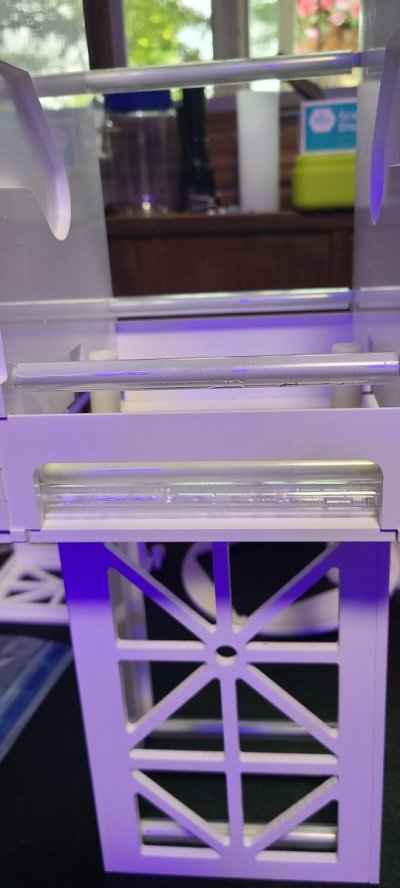

It's the 2nd roller guide before the fleece goes down into the cage portion. Might be a few days before I can get you a pic.

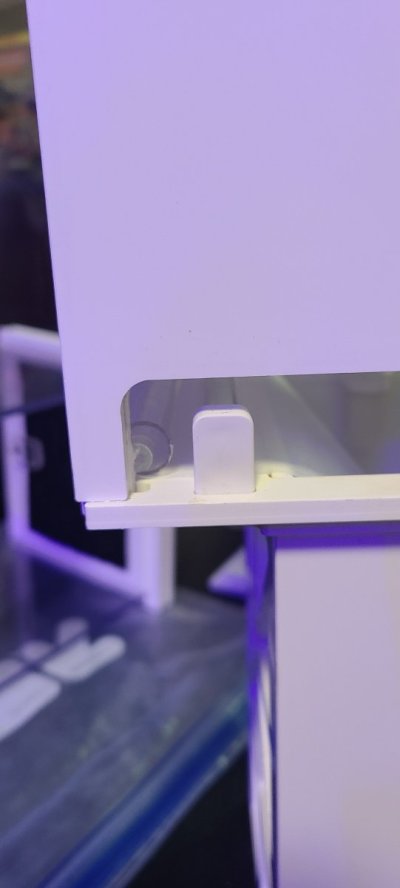

Basically, you are trying to provide some tension there so that when the water starts to rise from dirty fleece, the fleece stays taunt to keep the water area in the cage from seeping out the sides which usually happens on the clean roll side of the cage near the top portion. (If this happens to your unit)

Basically, you are trying to provide some tension there so that when the water starts to rise from dirty fleece, the fleece stays taunt to keep the water area in the cage from seeping out the sides which usually happens on the clean roll side of the cage near the top portion. (If this happens to your unit)