For a span that size, I recommend a 2X8 top frame to minimize deflection. The uprights and base can be 2X4. I recommend stabilizing boards between the front and back rails to ensure they don’t twist plus a plywood top.

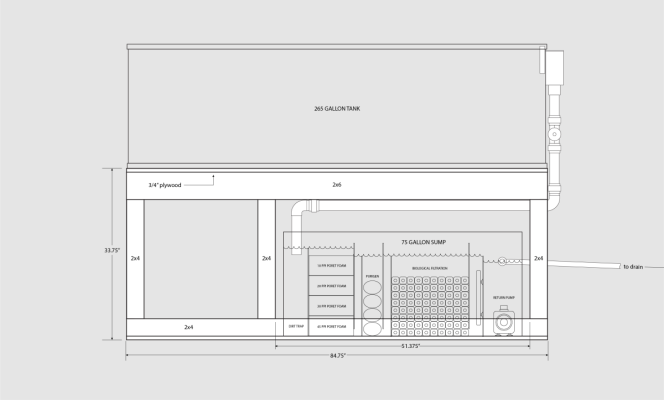

Thanks, yes I plan to add boards between the top rails to help with racking. I also plan to skin 3 sides with 3/4" ply as well as the top and bottom. I modified my design to add in 1 support at 1/3 the span and plan to have 2 on the back side. This would give me an approx. span of 51.375". Do you see any issues with this span using 2x6 and skinning. I also plan to screw and glue all my joints. I would like to avoid a 2x8 so I can get a 75 gallon sump inside comfortably and have more room to work. Speaking of that do you see any issues with having it sitting directly on a 3/4" plywood base? I will need to shim up on side about 1/4" as my floor slopes to my drain. Will that amount of weight cause the plywood to bend?