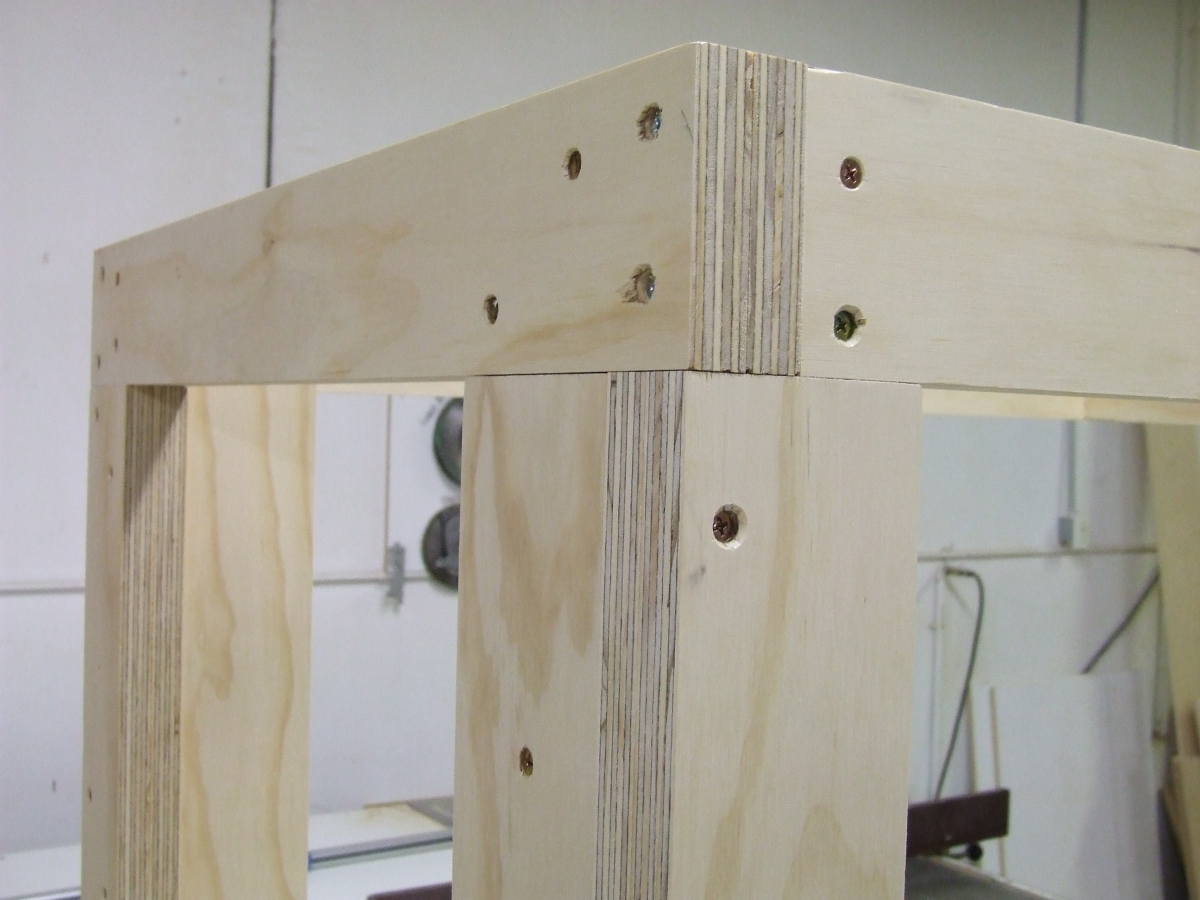

I created a mockup out of 1x2's. It will be slid down the stairs which are carpeted and then stood up briefly to make the turn at the bottom. It'll be a little awkward but it'll fit. (gulp)I was actually wondering how you were going to get the tank down there

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Structural engineers: Please HELP with 7 foot DIY stand build.

- Thread starter mjovic

- Start date

- Tagged users None

Interesting idea. Hadn't considered installing on site. What do you mean by a slip joint?You can have them build it to be assembled on site with slip joints and bolts.

I did that with the stand on my 150 gallon frag tank. Was too wide and tall to make it through an interior door.

This looks amazing! Why did you choose not to go this route? Also, where can I find plans to this build and has anyone run analysis on height of the beam and spans for taking this approach? Is there a thread that discusses this type of build? @RocketEngineer your thoughts? I don't have a great table saw (just a mini portable jobsite one) so the 2x construction method was more appealing, but maybe I just need to man up, haha.If you are dead set on wood, I would recommend you also consider this plywood design; which was my original choice.

Interesting idea. Hadn't considered installing on site. What do you mean by a slip joint?

Basically the stand was in 2 pieces.

The stand was built were the connections were that a slightly larger sleeve was on one part of the stand, that the other part could be slipped into and then bolted together.

I would never put two pieces of wood together to make it stronger. I would always go for a thick piece of wood. I used 4X4sWhat do you think about "engineering" the 4x4 w2x4's? Glue and screw ..

Maybe plywood but I wouldn't glue 2x4s together to make a 4x4.I would never put two pieces of wood together to make it stronger. I would always go for a thick piece of wood. I used 4X4s

Ahh. I think I understand. Kind of like how plastic modular shelving slips over the legs? That's actually a pretty viable option. Looking to keep costs in the sub $1k range which is why DIY is appealing. Wondering how much a fabrication shop would charge for something like that.Basically the stand was in 2 pieces.

The stand was built were the connections were that a slightly larger sleeve was on one part of the stand, that the other part could be slipped into and then bolted together.

Ahh. I think I understand. Kind of like how plastic modular shelving slips over the legs? That's actually a pretty viable option. Looking to keep costs in the sub $1k range which is why DIY is appealing. Wondering how much a fabrication shop would charge for something like that.

I paid way under that, just found local welders.

Second person I used was also into the hobby.

@RocketEngineer can you please calculate the deflection in the three scenarios below? I've read through all 230+ pages of the split thread in the other forum but amazingly I'm still not sure! Better to be safe than sorry. Thank you!

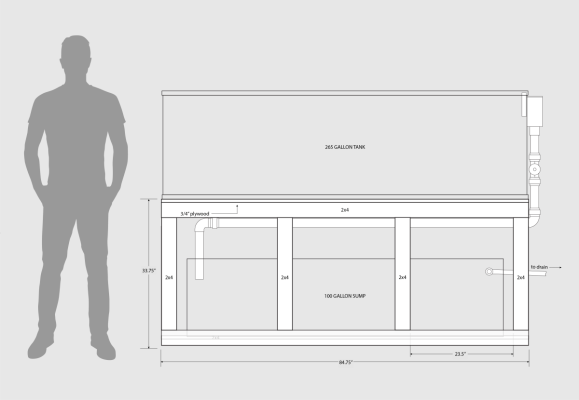

Stand Dimensions: 84.75" L x 30.75" W x 34" H

Tank Dimensions: 84" L x 30" W x 24" H (265 gallons)

Option 1

2x8 top rail. 74.75" opening (84.75" - 3.5" - 3.5" - 1.5" - 1.5")

Deflection:

Option 2

2x8 top rail. 66.75" opening (with adding 2x4 uprights inward 4" on either side to lessen the opening)

Deflection:

Option 3

2x6 top rail. 51.25" opening (adding one offset upright at 1/3 the distance 84.75" x .667 - 3.5" - 1.75")

Deflection:

Stand Dimensions: 84.75" L x 30.75" W x 34" H

Tank Dimensions: 84" L x 30" W x 24" H (265 gallons)

Option 1

2x8 top rail. 74.75" opening (84.75" - 3.5" - 3.5" - 1.5" - 1.5")

Deflection:

Option 2

2x8 top rail. 66.75" opening (with adding 2x4 uprights inward 4" on either side to lessen the opening)

Deflection:

Option 3

2x6 top rail. 51.25" opening (adding one offset upright at 1/3 the distance 84.75" x .667 - 3.5" - 1.75")

Deflection:

- Joined

- Sep 18, 2017

- Messages

- 5,604

- Reaction score

- 3,450

Wood Beam Span Calculator

Use this wood beam span calculator to check a wood beam of a particular size and length to see if it can support a given uniform linear load by comparing its allowable and required bending and shear stress.

Kind of all there.....

8.554 lbs / gallon saltwater

261.82gal = 2239.6lbs

300lbs 2" sand

Suppose one needs to add glass and rock though rock will displace water.

3500lbs if I guess at 1000lbs of glass

(see correction below)

Rimless est. w/ 3.8 safety factor

1/2" glass sides, (10sq ft + 28.2) 38sq ft 6.36#/sq ft = 242#

3/4" glass bottom 17.4 sq ft

17.5sq ft 9.1# sq ft 159#

TOTAL glass 401#

2941 total lbs

17.5 sqft

169 lbs/sqft

make it simple-ish

200lbs/ sqft

Example: spf grade2 2x8 weight calc of 200 lbft/ft

Beam span of 84( why not)

Any other scenario will be less since you are dividing the span.

0.146".deflection.

2x6 @54" 0.063"

Option 2 0.059"

you can double check the calcs.no guarantee.

"In my opinion" if you do full free span a 2x10 is best.

- Joined

- Sep 18, 2017

- Messages

- 5,604

- Reaction score

- 3,450

A tank glass plus water calc.

www.hamzasreef.com

www.hamzasreef.com

2482.1#

/17.5 = 142#/sq ft

Tank Weight Calculator

Aquarium calculator; Calculate both the full and empty weights for various shapes and sizes of aquariums.

2482.1#

/17.5 = 142#/sq ft

Last edited:

Wood Beam Span Calculator

Use this wood beam span calculator to check a wood beam of a particular size and length to see if it can support a given uniform linear load by comparing its allowable and required bending and shear stress.www.omnicalculator.com

Kind of all there.....

8.554 lbs / gallon saltwater

261.82gal = 2239.6lbs

300lbs 2" sand

Suppose one needs to add glass and rock though rock will displace water.

3500lbs if I guess at 1000lbs of glass

(see correction below)

Rimless est. w/ 3.8 safety factor

1/2" glass sides, (10sq ft + 28.2) 38sq ft 6.36#/sq ft = 242#

3/4" glass bottom 17.4 sq ft

17.5sq ft 9.1# sq ft 159#

TOTAL glass 401#

2941 total lbs

17.5 sqft

169 lbs/sqft

make it simple-ish

200lbs/ sqft

Example: spf grade2 2x8 weight calc of 200 lbft/ft

Beam span of 84( why not)

Any other scenario will be less since you are dividing the span.

0.146".deflection.

2x6 @54" 0.063"

Option 2 0.059"

you can double check the calcs.no guarantee.

"In my opinion" if you do full free span a 2x10 is best.

You are correct in calculating tank weight of approx. 400 lbs. I have been estimating total weight to be ~3000 lbs for a margin of safety.

As far as using a 2x10, I am height constrained by low ceilings so I can only really make the stand 34" tall before I run into issues servicing the tank from above and I would like to fit a 60g or 100g long sump. I basically have 3 options...2x4 header with 2 center supports front and 2 rear, 2x6 with 1 center support (likely offset to 1/3 length of the front) or a 2x8 with 2 additional 2x4's brought in a few inches from the edges to reduce the required front span. This is the calculation I am most interested in and one I don't believe you provided above? Looks like you ran a calculation with 84" span...I was thinking more like 67". Would it be possible to run that calc and provide the output?

I suppose that there could be a 4th option where I double up the 2x8 header...would it be possible to run a calculation using this scenario as well? Both at 74" and 67" spans? Thanks!

P.S. For consistency in measurement, how does your calculation compare to the formula @RocketEngineer uses? That has been the one I have based a lot of my assumptions on thus far. Thanks!

Last edited:

- Joined

- Sep 18, 2017

- Messages

- 5,604

- Reaction score

- 3,450

Doubling isn't that effective.

67" is .043" using #2 spf and 200 lbs/sq ft

Actually a 4x8 is 0.019. More than I pictured. Though that is solid wood.

.032 at 150 lbs/sqft

Keep in mind I just consider the lowest possible deflection not what is permissable.

Did find this:

www.reef2reef.com

www.reef2reef.com

For example, if you double the thickness or number of joists in a floor, the distance the boards can span will increase by approximately 25%. But if you double the width of the boards, the distance the joists can span increases between 80% to 100%, even though you're using the same board feet of lumber.Feb 25, 2014

67" is .043" using #2 spf and 200 lbs/sq ft

Actually a 4x8 is 0.019. More than I pictured. Though that is solid wood.

.032 at 150 lbs/sqft

Keep in mind I just consider the lowest possible deflection not what is permissable.

Did find this:

So the rule I was always told is no more than 3mm of deflection in the middle of any span, of any length, for a tank. That's just a hair under 1/8th inch, around 0.118"

Stand deflection

I am working on a new stand without a center brace in the front and trying to decide what on an allowable amount of deflection is acceptable for safety over time. I'm not so much worried about my stand failing, but I don't have first hand experience with long term effects on acrylic or glass...

www.reef2reef.com

www.reef2reef.com

Last edited:

Double checking that calculation was for a single 2x8 spanning 67" yielding .043" deflection? That would be acceptable. Curious what 74" would yield?Doubling isn't that effective.

67" is .043" using #2 spf and 200 lbs/sq ft

Actually a 4x8 is 0.019. More than I pictured. Though that is solid wood.

.032 at 150 lbs/sqft

Keep in mind I just consider the lowest possible deflection not what is permissable.

Did find this:

Stand deflection

I am working on a new stand without a center brace in the front and trying to decide what on an allowable amount of deflection is acceptable for safety over time. I'm not so much worried about my stand failing, but I don't have first hand experience with long term effects on acrylic or glass...www.reef2reef.com

Thanks for the quick response. Interesting that it jumps only .022" going from 67 and 74" (+7"), but .081" going from 74" to 84" (+10"). Is that correct? Did I read that right?.065.............

So to summarize:

2x8

67" span = .043" deflection

74" span = .065" deflection

84" span = .146" deflection

2x6

54" span = .063" deflection

Can any other engineers confirm these calculations? Looking to start the build next weekend. Thanks!

This is a great idea! I think I built mine one Sunday after church. It’s for a 40gal breeder.Just find a local welder, will do it cheap... can either powder coat or spray it.

Should easily be able to cover your desired span using metal.

Cost was 50 bucks in steel

Attachments

Here it is mocked up with 2x4's. I'm not hating it. I like the head space above. What would be the deflection here with spaced out every 24" or so?

Attachments

-

tank_design 33.75%22 high - 75 gallon sump copy [email protected]44.2 KB · Views: 53

tank_design 33.75%22 high - 75 gallon sump copy [email protected]44.2 KB · Views: 53

- Joined

- Sep 18, 2017

- Messages

- 5,604

- Reaction score

- 3,450

0.018"

But at this point I personally start to consider the "legs" and bowing..

Should be fine though.

But at this point I personally start to consider the "legs" and bowing..

Should be fine though.

Different subject just for reference:a single 8 ft 2x4 column, in compression, can hold up over 2000 lbs, depending on the actual wood species. Again, ignoring bending or buckling of the 2x4

Last edited:

Similar threads

- Replies

- 24

- Views

- 753

New Posts

-

Livestock PHYTOPLANKTON AND COPEPOD CULTURE KITS

- Latest: Reef By Steele

-

-

How is a drilled overflow more reliable than siphon?

- Latest: michigan-reef