Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Screen Net Tops: Tips, Tricks, and Pics!

- Thread starter Bulk Reef Supply

- Start date

- Tagged users None

- Joined

- Jun 3, 2017

- Messages

- 181

- Reaction score

- 181

I used BRS 1/8" netting and the spline in a DIY frame made of a solid 1/4" thick sheet of acrylic. Works much better on complex shapes and a whole lot stronger.

This is genius.....pure genius!!! Thank you for the new idea for my curved corners QT tank cover!!

- Joined

- Mar 11, 2017

- Messages

- 468

- Reaction score

- 301

My trick is that the back 3" of my tank is covered by black eggcrate, which is easy to make cutouts in for power cords (powerheads etc). The rest is a screen a la BRS window frame. I then made a tab (clear packing tape) that sticks up from the back of the window screen part. When it's feeding time, I pick the back edge of the lid by the tape tab and slide it back 3". I now have open space that's easy to get to, and the top then slides right back into place when I'm done.

- Joined

- Mar 14, 2017

- Messages

- 171

- Reaction score

- 139

Nice to see all these very nicely crafted aquarium covers! Great work.

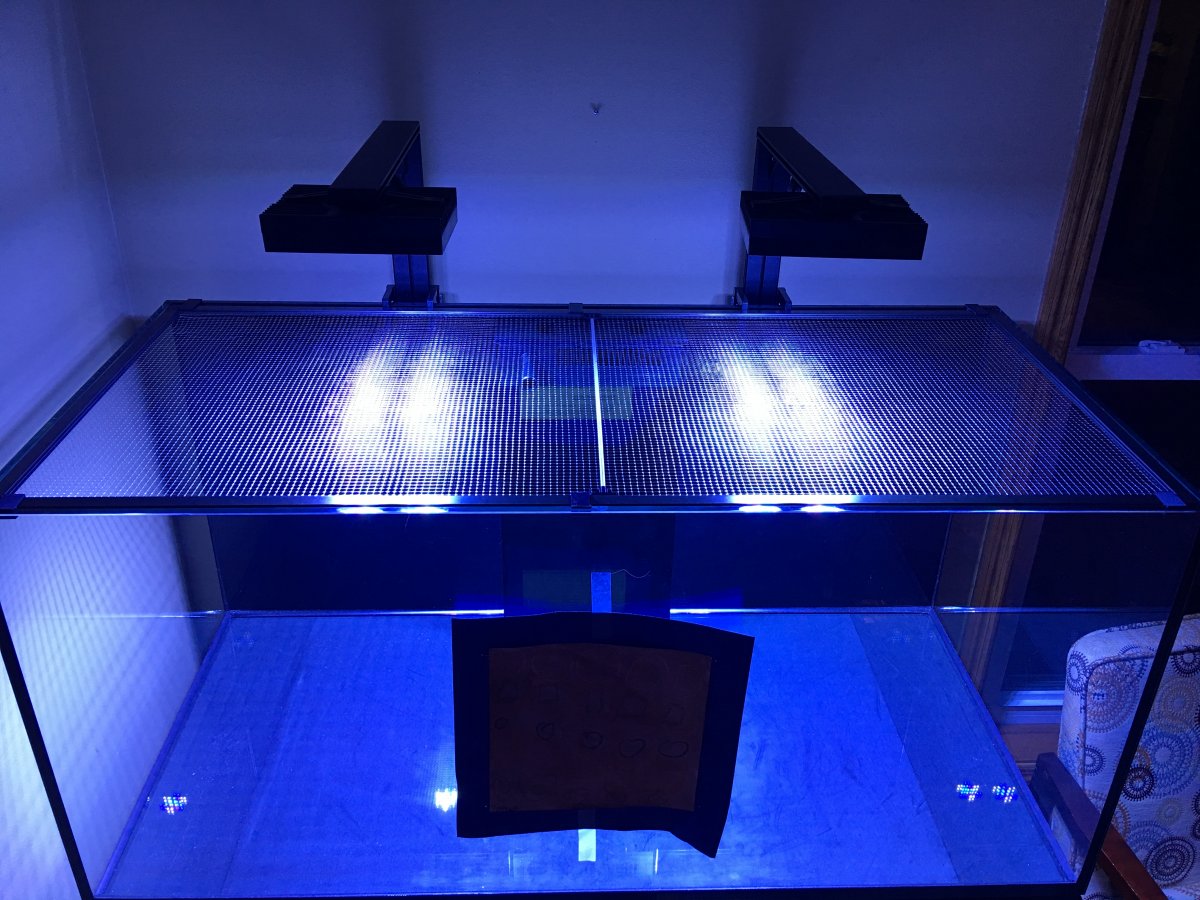

I have installed this cover to my aquarium, extremely effective, and it is barely visible with the lights on!

It looks like your edge netting is the exact FishGuard product from Bananaquarium, but it isn't available to buy yet on their website. Perhaps you are involved with the company or testing it. Is there a way to get one early? Or is there an update on when it will be available? I've read most jumps happen along the edge of the tank, so I've been looking for such a solution as a balanced compromise.

Watching...

Cuple of tips.

1/ My tank is 4'6"long and 2 screens are easier to manage than one.

2/ I glued an RO cartridge sealing ring to the mesh then cut the centre out and covered it with a large sucker now I don't have to lift a cover to feed.

1/ My tank is 4'6"long and 2 screens are easier to manage than one.

2/ I glued an RO cartridge sealing ring to the mesh then cut the centre out and covered it with a large sucker now I don't have to lift a cover to feed.

Everything has to look top quality. No saggy screens or misalignment to the grid pattern, it all has to be perfect especially for how much it cost. Even now, I'm going to flame polish the edge to give it a glass like finish vs a machine cut.That was my first thought too.

Stop looking at your lid and look at your fish and coral more.

I understand when you spot something that bugs you and you can't avoid seeing it.

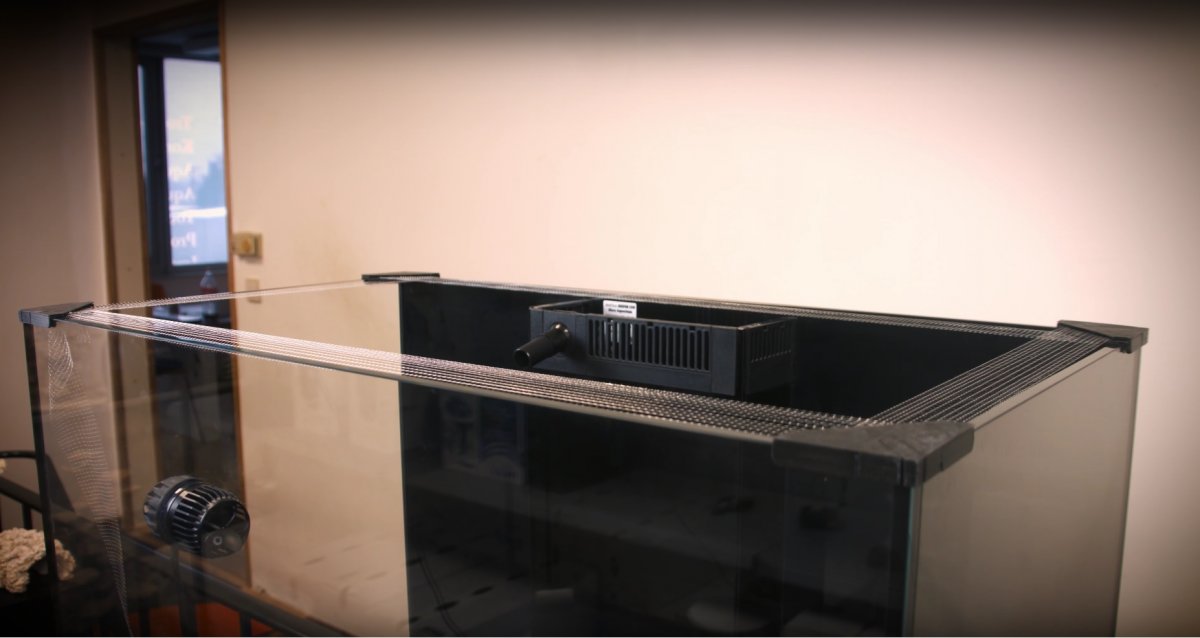

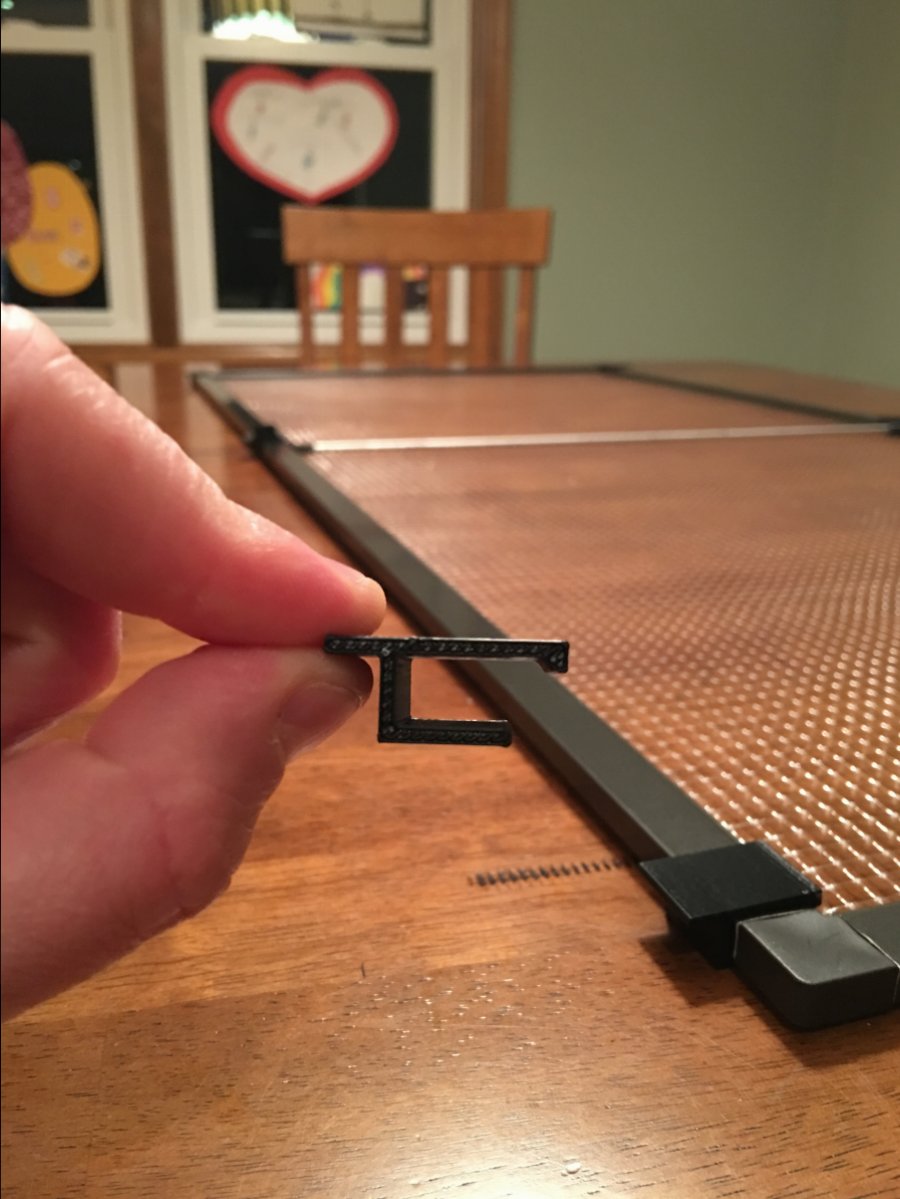

here is my solution for screens on a eurobraced tank. I used "polycarbonate h jamb" in the size that matched my screen frame thickness. This is the stuff you use on frameless glass shower enclosures for the door to seal against. I was looking for a solution because I couldn't stand the idea of having this beautiful eurobraced tank and just having a screen sit on top. the screen sits flush with the top of the glass. The screen is the BRS stuff.

The polycarbonate h jamb works pretty good.

I found it on amazon for $15 for a 8' piece.

Is that a Neptune feeder? I assume you don't have to cut a hole for it and the food falls through the netting.

I made mine from 1/4" acrylic too. It was what I had left over from building my sump. Acrylic absorbs water so it starts to pull up from the corners over time. It's symmetrical though so I simply flip it over and it starts over.

My tank is 48"x30" so I wanted the center "brace" to hold up the screen over the length. I also set up my auto feeder on top of it to drop pellets through the screen. The auto feeder sits over the top of the overflow. I have the apex turn off the return pump a couple mins before it feeds so that the food doesn't just go down the overflow.

I used an 1/8" bit as well to route the groove for the spline. There are different thickness splines so make sure you match up your groove with the spline you get. Also routing an 1/8" into the side of 1/4" material isn't the easiest thing to do. It leaves only 1/16" on either side.

Exactly.Is that a Neptune feeder? I assume you don't have to cut a hole for it and the food falls through the netting.

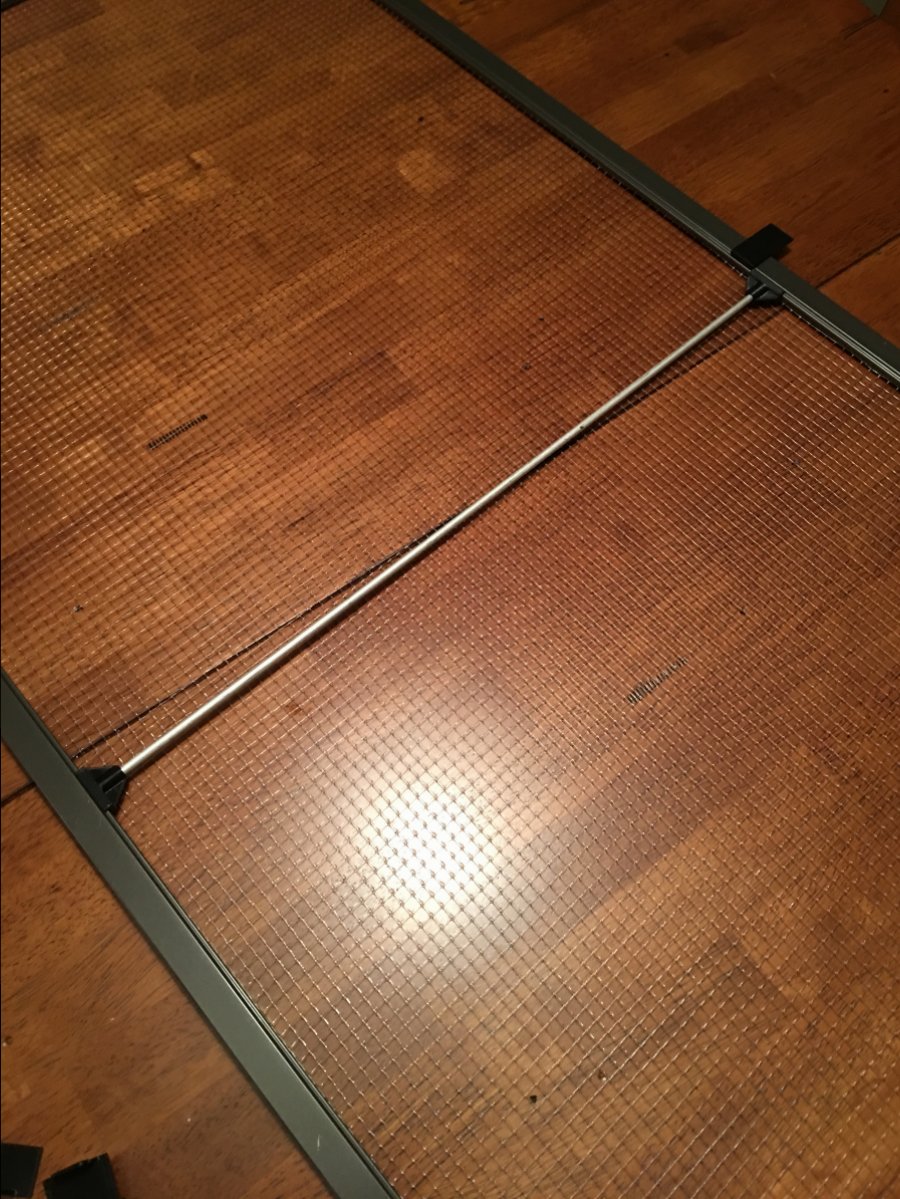

I had trouble keeping the frame from bowing when I got the mesh tight enough to prevent sagging. It took a couple tries but I finally achieved a nice result by adding a center brace. Also designed and 3D printed some supports to hold the frame flush.

I had trouble keeping the frame from bowing when I got the mesh tight enough to prevent sagging. It took a couple tries but I finally achieved a nice result by adding a center brace. Also designed and 3D printed some supports to hold the frame flush.

Great solution!!

This thread has been dormant for a couple of months buy I have a question: I'm doing an upgrade to a 120 and I decided to go over the top with the return. I need to figure out an inside corner for a frame, since the return pipe will have to be accomodated for. I've never worked with acrylic and I'm not sure that the screen door corner pieces can be manipulated to work in the manner that I need.

- Joined

- Sep 7, 2016

- Messages

- 1,425

- Reaction score

- 990

This thread has been dormant for a couple of months buy I have a question: I'm doing an upgrade to a 120 and I decided to go over the top with the return. I need to figure out an inside corner for a frame, since the return pipe will have to be accomodated for. I've never worked with acrylic and I'm not sure that the screen door corner pieces can be manipulated to work in the manner that I need.

I did do reverse turns on mine as a cut out for my HOB stuff, but it requires shaving away like half of the angle adapter and it's not super confidence inspiring in the rigidity department.

- Joined

- Mar 11, 2017

- Messages

- 468

- Reaction score

- 301

This thread has been dormant for a couple of months buy I have a question: I'm doing an upgrade to a 120 and I decided to go over the top with the return. I need to figure out an inside corner for a frame, since the return pipe will have to be accomodated for. I've never worked with acrylic and I'm not sure that the screen door corner pieces can be manipulated to work in the manner that I need.

Just use a regular rectangle for most of the lid, and a strip of eggcrate in the back for the cutouts. That's what I did after seeing someone else do the same thing

I thought about this and was concerned about the structural integrity as well.I did do reverse turns on mine as a cut out for my HOB stuff, but it requires shaving away like half of the angle adapter and it's not super confidence inspiring in the rigidity department.

I guess this would work albeit a last resort.Just use a regular rectangle for most of the lid, and a strip of eggcrate in the back for the cutouts. That's what I did after seeing someone else do the same thing

Thanks guys, anyone else?

I don't mind the idea of the egg crate on the back for power cords, it's pretty smart. But can you not just cut a small square into the screen close to the corner for cords? or does that compromise the integrity of the screen too much? The other question is for ell owners. How do you secure the lid to the tank to help prevent them from pushing up on the lid?

For the cable management, I would suggest the 'Bananaquarium Fishguard': some system that prevents a big portion of jumping fish, and which can be combined with a total cover screen: the screen can be placed on top of the fishguard corner pieces.

Similar threads

- Replies

- 4

- Views

- 246

- Replies

- 26

- Views

- 1,097

- Replies

- 4

- Views

- 236

TOP 10 Trending Threads

- Replies

- 82

- Views

- 1,601

- Replies

- 54

- Views

- 453

- Replies

- 28

- Views

- 250

- Replies

- 107

- Views

- 1,658

- Replies

- 20

- Views

- 378

- Replies

- 52

- Views

- 1,144

- Replies

- 36

- Views

- 571

- Replies

- 22

- Views

- 386

-

- Poll

- Replies

- 28

- Views

- 376